Heat dissipation unit and heat dissipation device thereof

A heat dissipation unit and heat dissipation device technology, which is applied in the direction of electrical components, cooling/ventilation/heating transformation, instruments, etc., can solve the problems of large volume and poor heat dissipation efficiency of heat dissipation devices, and achieve the effect of small size and extremely poor heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above objects of the present invention and their structural and functional characteristics will be described with reference to the preferred embodiments of the accompanying drawings.

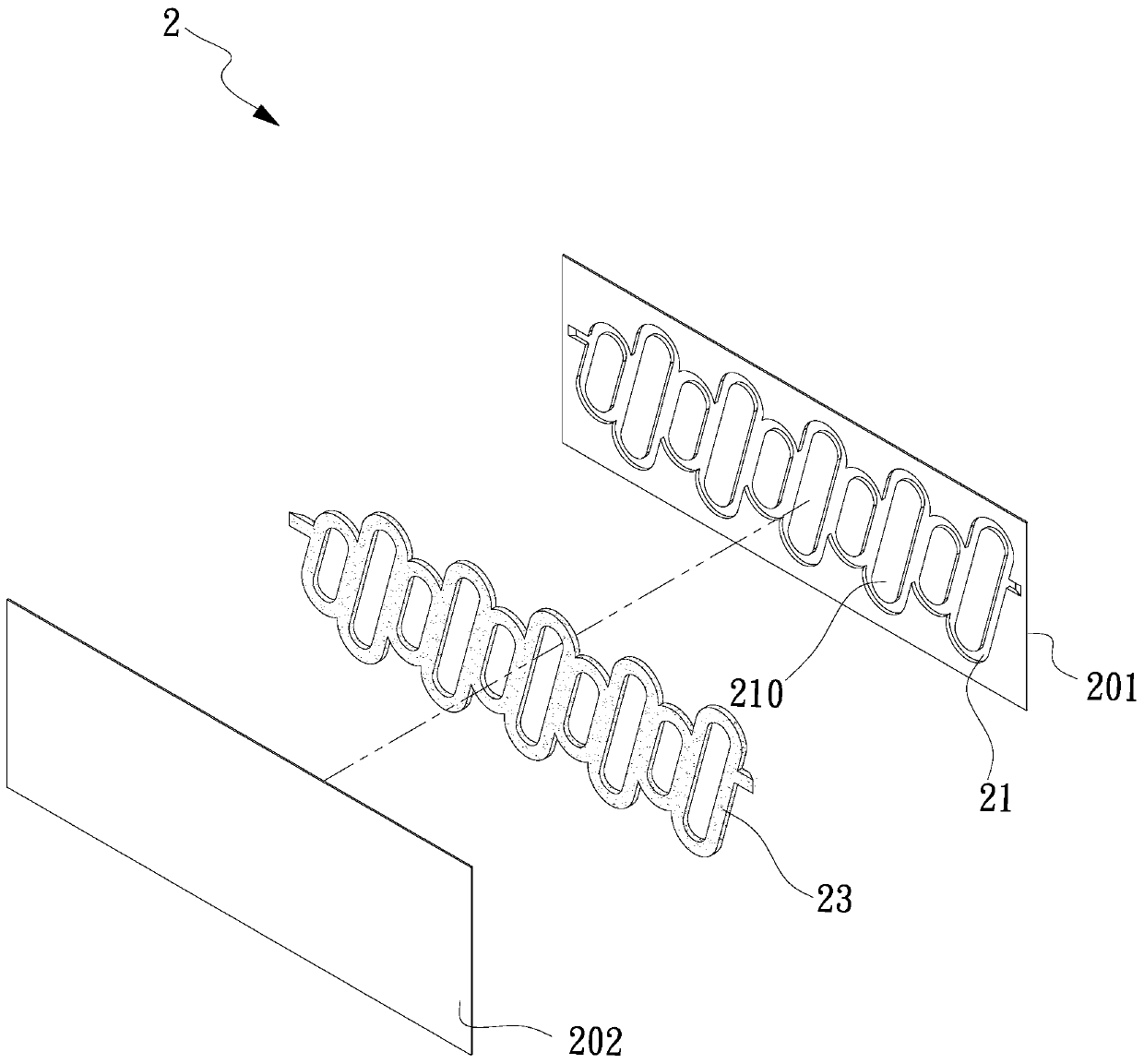

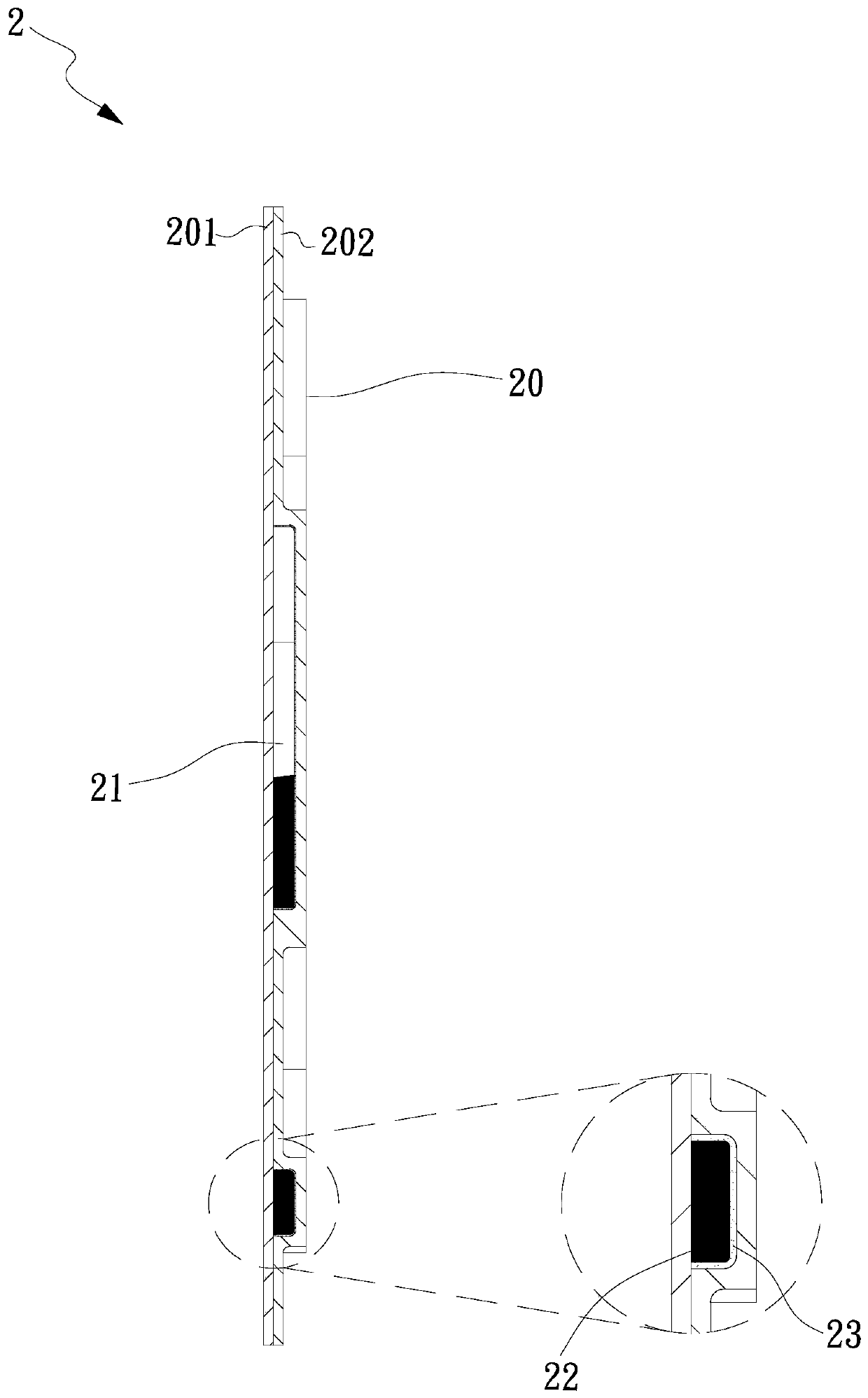

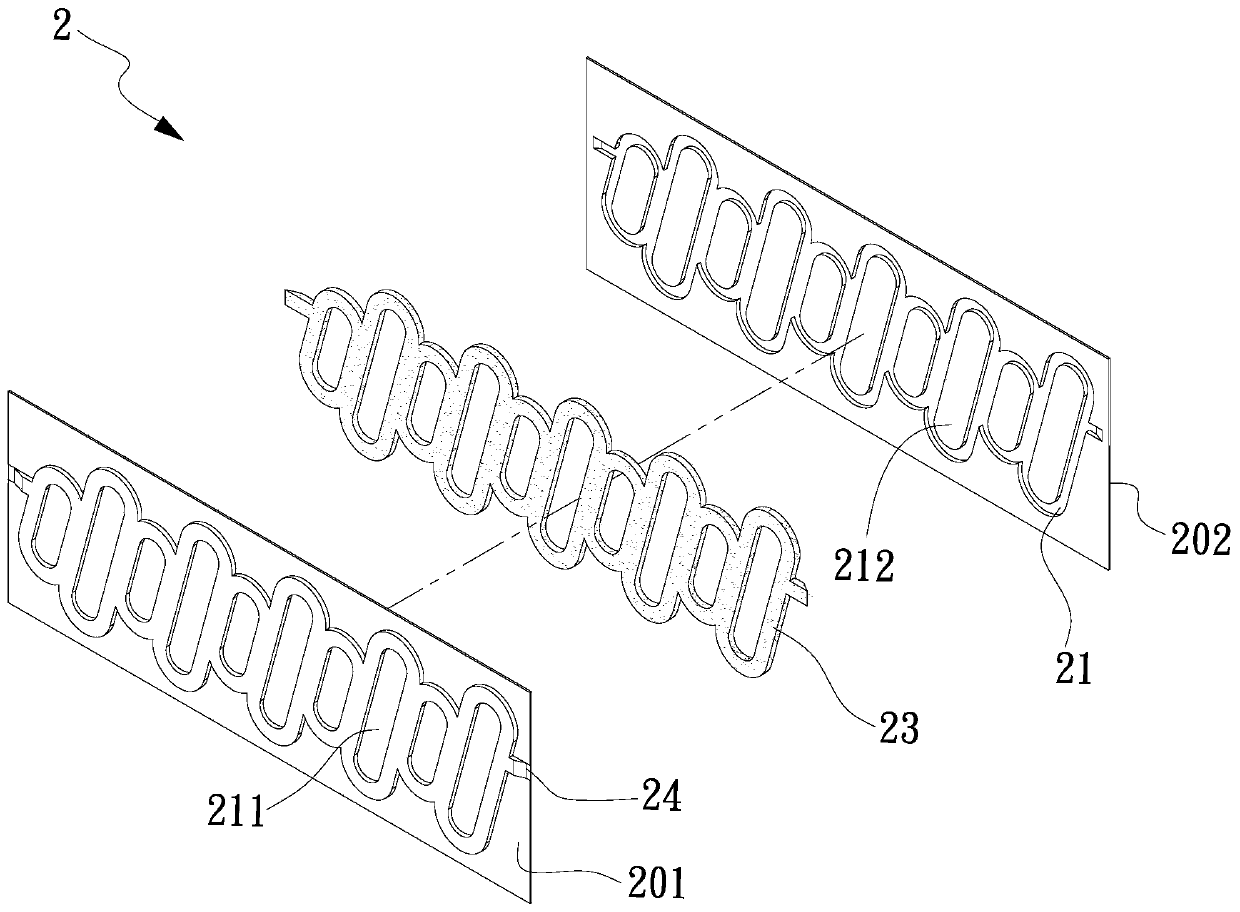

[0045] see figure 1 , figure 2 , is a perspective exploded view and a cross-sectional view of the first embodiment of the heat dissipation unit of the present invention. As shown in the figure, a heat dissipation unit 2 has at least one heat dissipation fin 20, and the heat dissipation fin 20 is formed by a first plate body 201. and a second plate body 202 correspondingly covered, in this embodiment, at least one groove 210 is formed on the first plate body 201 (of course, the second plate body 202 can be optionally formed with the above-mentioned groove 210 ). The groove 210 is described by the first plate body 201 in this embodiment). More specifically, the first plate body 201 of the heat dissipation fin 20 in this embodiment has a groove 210 structure, and the second plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com