Falling and block-cutting linked broccoli block-cutting corer with two-level self-adaptive cutting depth

A cutting depth and self-adaptive technology, applied in metal processing and other directions, can solve problems such as dense distribution of flower buds, uneven cutting of large-diameter broccoli, and uneven distribution of broccoli flower diameters, so as to improve adaptability and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

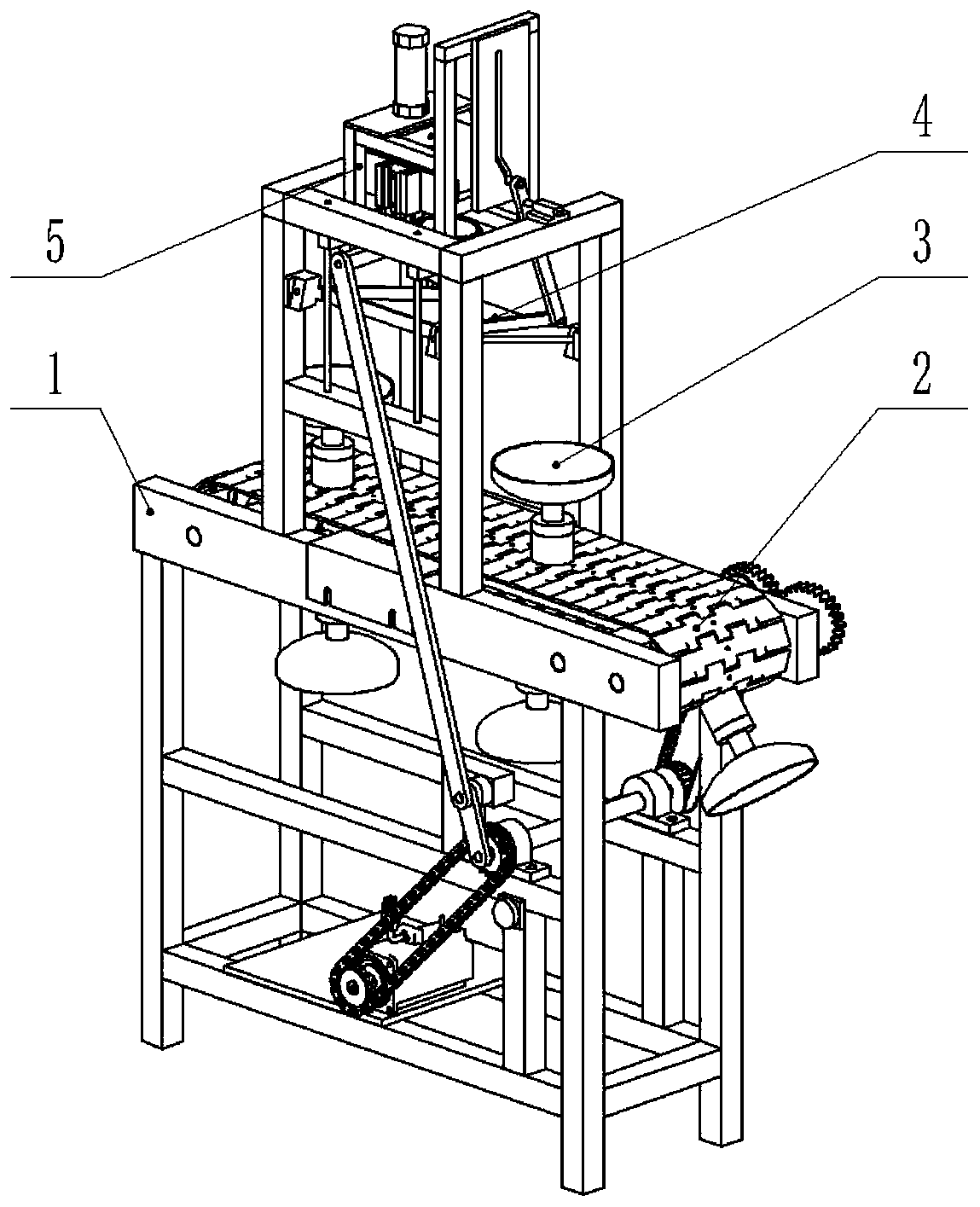

[0033] Such as figure 1 As shown, the two-stage adaptive cutting depth blanking and dicing linkage broccoli dicing and coring machine includes a frame 1 , a conveying component 2 , a tray component 3 , a blanking component 4 and a cutter component 5 .

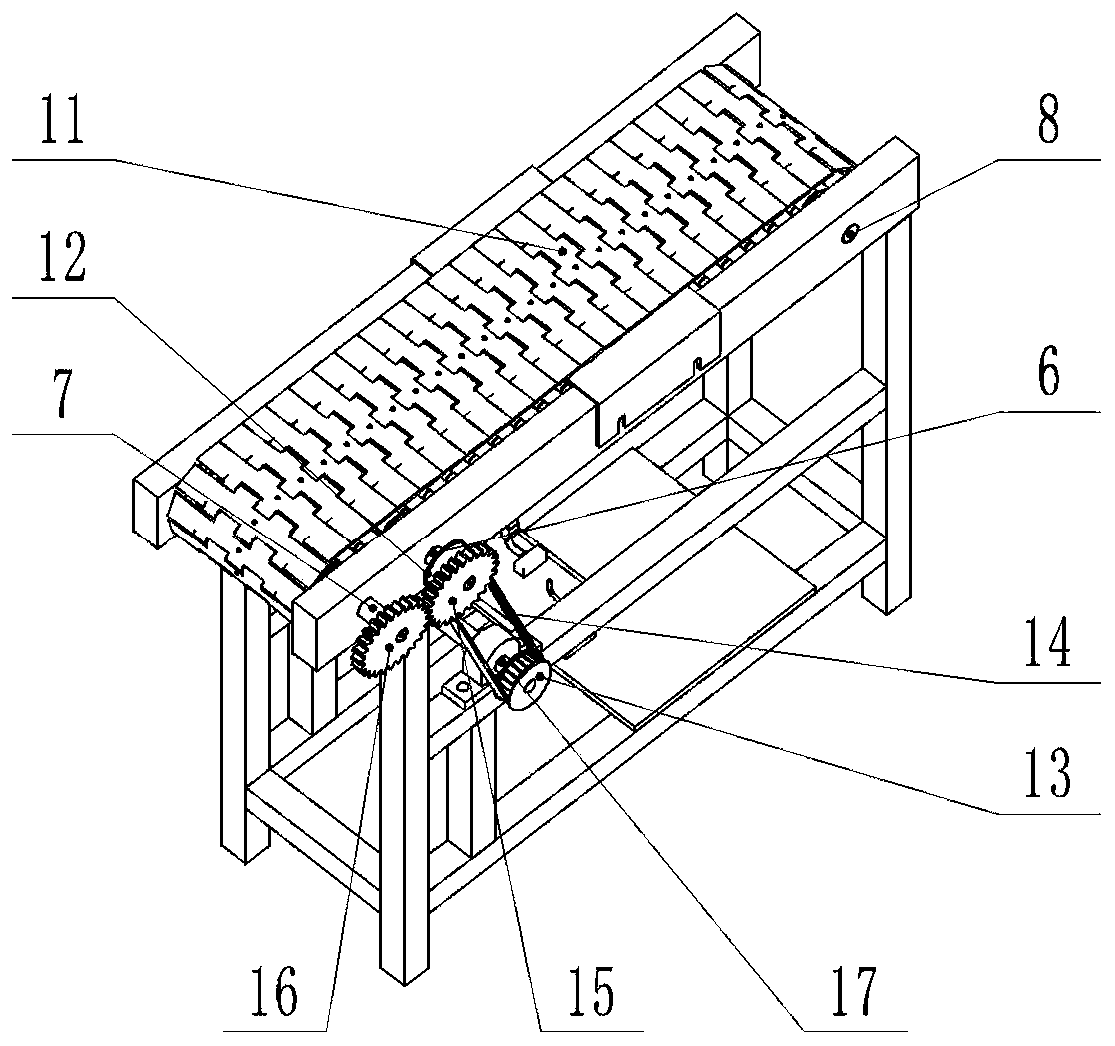

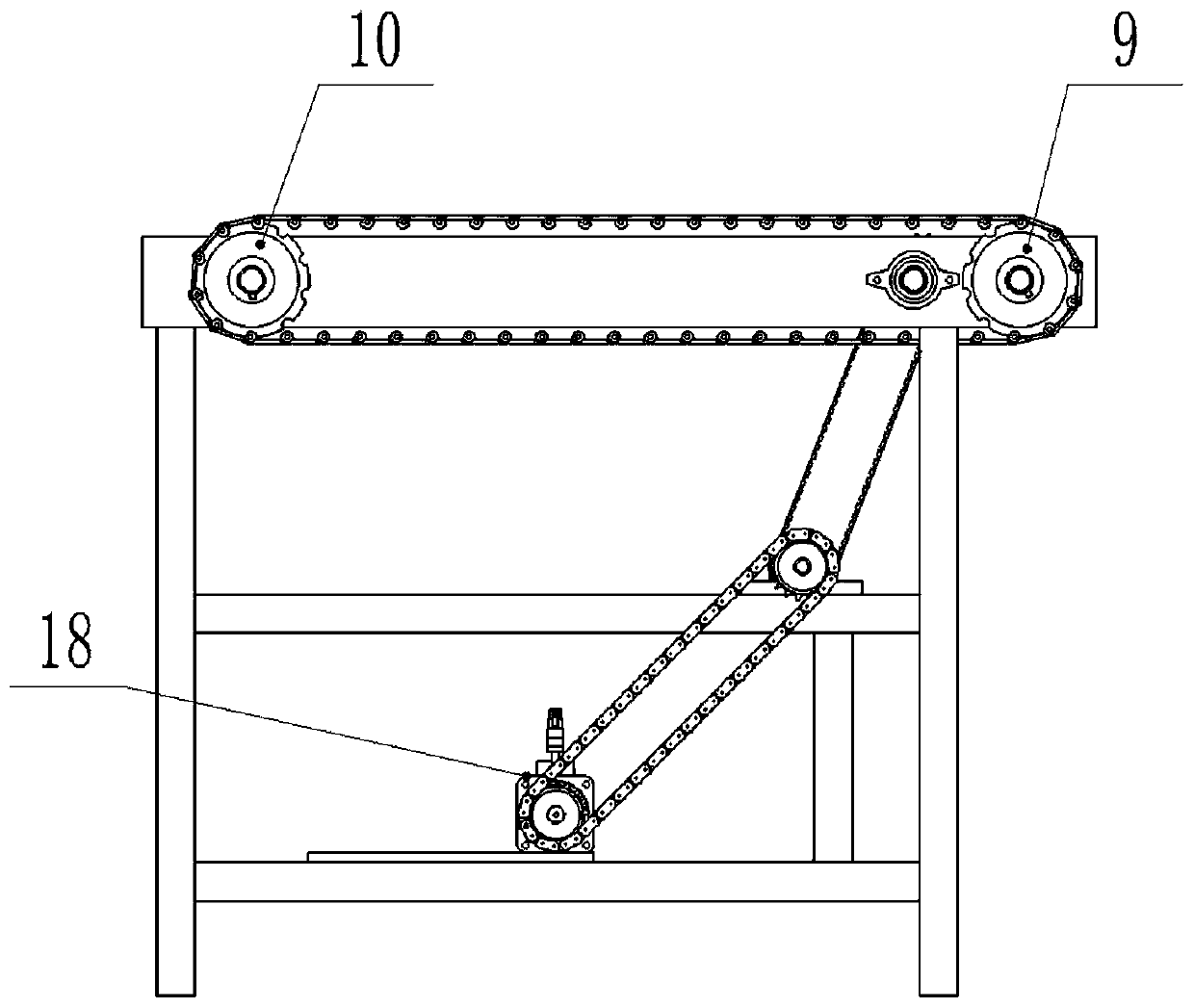

[0034] Such as figure 1 , 2As shown in and 3, the conveying assembly 2 includes a first input shaft 6, a second input shaft 7, a driven shaft 8, a conveying driving sprocket 9, a conveying driven sprocket 10, a conveying chain plate 11, a first synchronous pulley 12 , the second synchronous pulley 13, synchronous belt 14, driving non-circular gear 15, driven non-circular gear 16, drive shaft 17 and stepping motor 18; the size of the first synchronous pulley 12 and the second synchronous pulley 13 is equal One end of the frame 1 forms a revolving pair with the first input shaft 6 and the second input shaft 7, and the other...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap