Chained blow-molded bottle blank-pressing device

A preform pressing and chain-type technology, which is applied in the field of chain-type blow molding bottle preform pressing devices, can solve the problems of low processing cost, restriction of high-speed blow molding efficiency of blow molding bottles, and loose structure, so as to achieve compact structure and improve blow molding efficiency , the effect of high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

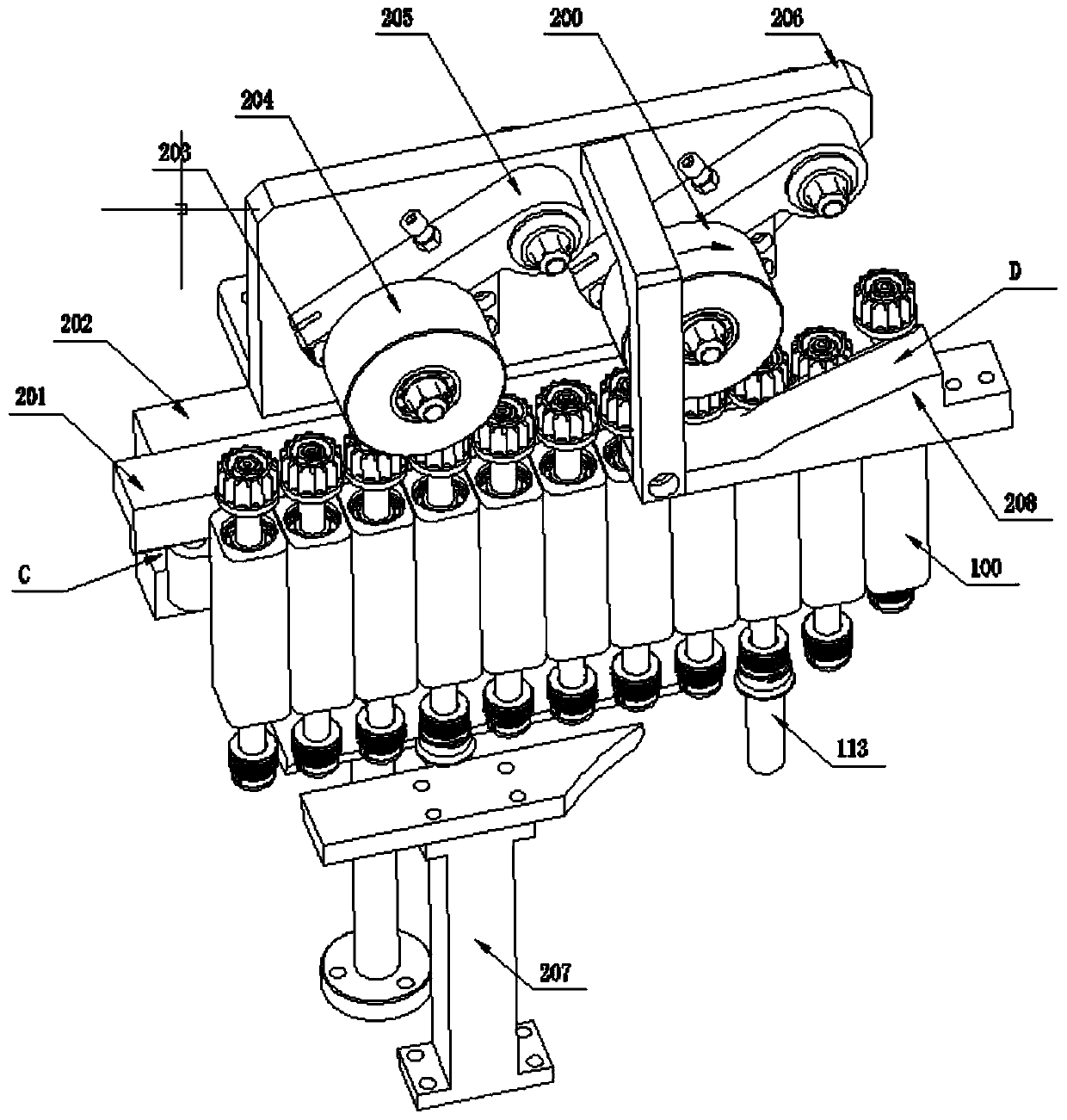

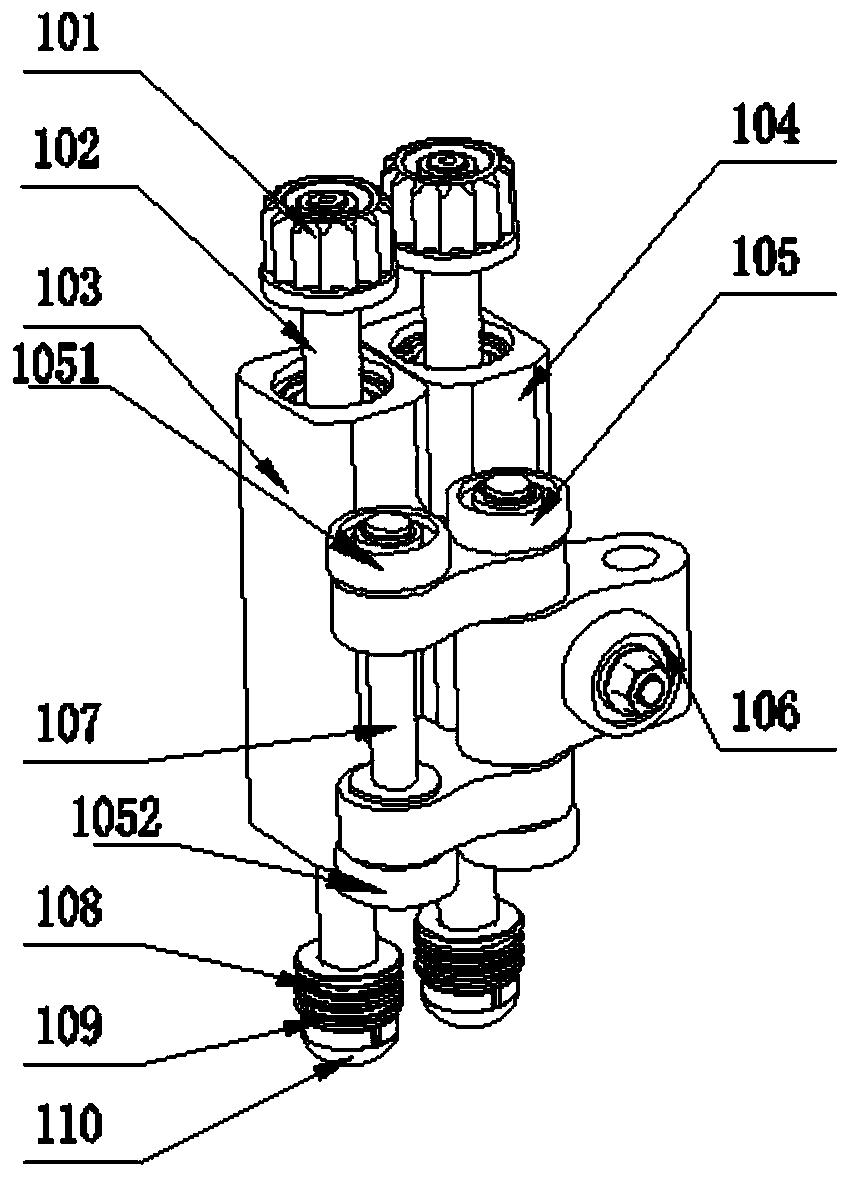

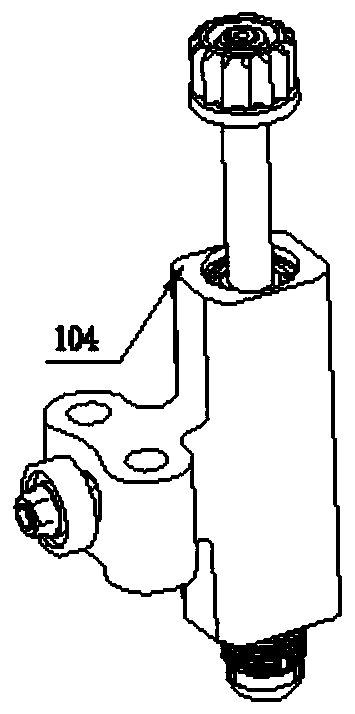

[0038] A chain-type blow molding bottle preform pressing device, comprising a chain-type embryo-solidifying mechanism 100 and a embryo-guiding mechanism 200. The chain-type embryo-solidifying mechanism 100 includes a plurality of embryo-solidifying units, and the plurality of embryo-solidifying units are arranged side by side in sequence and Connected in a row, the embryo guiding mechanism 200 includes a embryo-inserting device and a guide rail, and a plurality of the embryo-solidifying units move along the rail, and the embryo-inserting device is used to insert the embryo-solidifying unit into the corresponding preform 113 .

[0039] As a further solution of this embodiment, the embryo-solidifying unit includes an embryo head seat, a slider and a preform connecting device, the guide rail is arranged horizontally, the embryo head seat moves along the guide rail, and the slider is vertical Pass through the embryo head seat and slide up and down driven by the embryo inserting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com