Single-station and double-station dual-purpose full-automatic plastic extrusion blowing machine

A double-station, fully automatic technology, applied in the field of plastic bottle blowing, to achieve the effect of reducing pollution, increasing moving speed, and reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

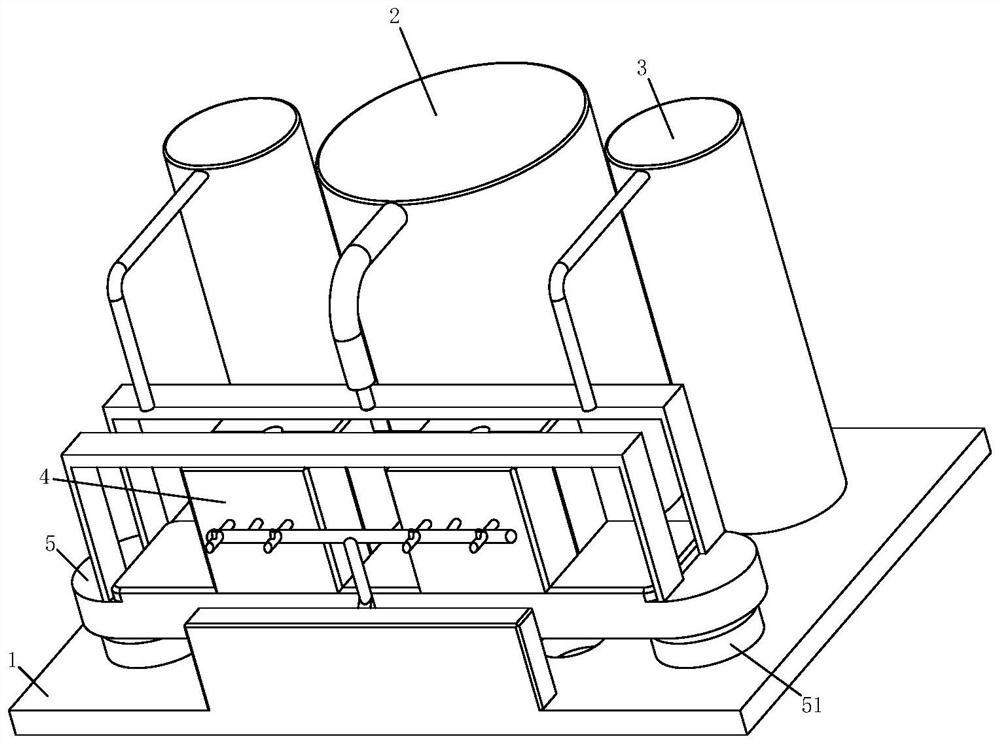

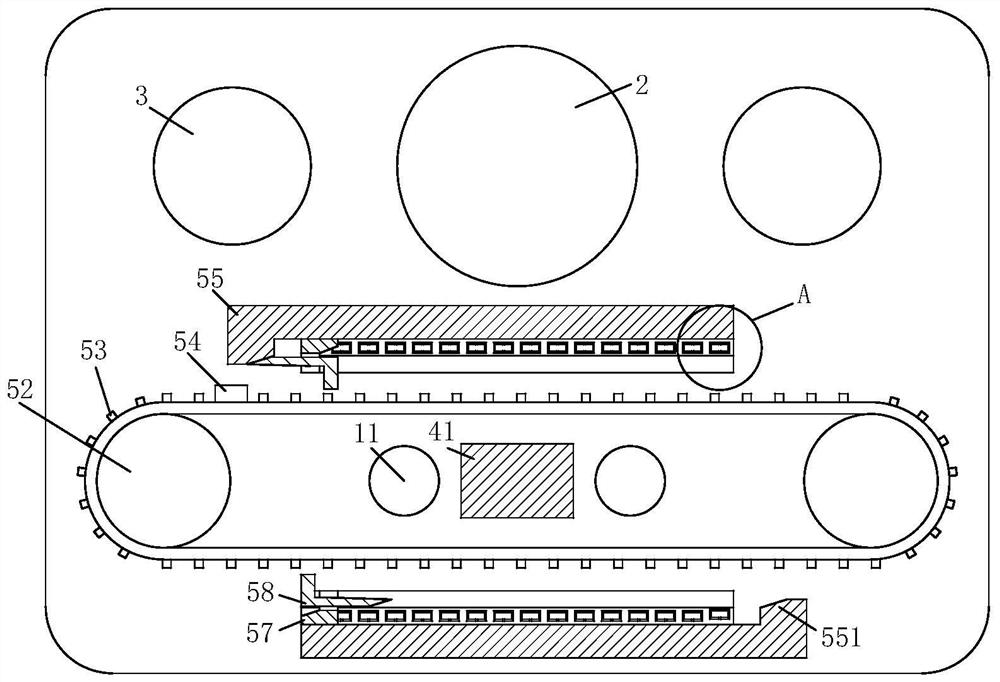

[0068] As a specific embodiment of the present invention, the driving structure 5 includes:

[0069] a base 51, the base 51 is fixed on the frame 1;

[0070] a rotating wheel 52, the rotating wheel 52 is rotatably connected with the base 51;

[0071] a chain 53, the chain 53 is engaged with the rotating wheel 52;

[0072] a top block 54, the top block 54 is fixedly connected with the chain 53;

[0073] A fixing block 55, the fixing block 55 is fixedly connected with the frame 1, and one end of the fixing block 55 is provided with a slope 551;

[0074] A chute 56, the chute 56 is set in the fixing block 55;

[0075] The slider 57, the slider 57 is arranged in the chute 56;

[0076] The clamping block 58 is fixedly connected with the slider 57 , and the clamping block 58 is L-shaped and has elasticity.

[0077] When the switch is turned on, the controller on the frame 1 controls the power supply to provide power to the motor provided in the base 51, the motor works to drive...

Embodiment approach

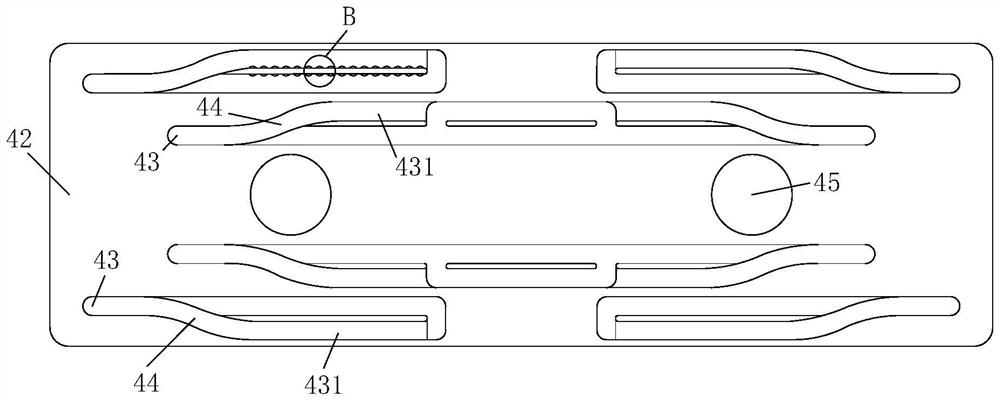

[0101] As a specific embodiment of the present invention, a ball groove 471 is provided at the bottom of the No. 1 protrusion 47 ; a ball 472 is provided in the ball groove 471 .

[0102] By arranging the ball groove 471 and the ball 472 in the No. 1 protrusion 47, the sliding friction of the mold 46 during the moving process is converted into rolling friction, and the friction between the mold 46 and the bottom of the straight chute 43 and the arc groove 44 is reduced. , to further improve the moving speed of the double-station molding mechanism 4, and further improve the blowing efficiency of the single- and double-station dual-purpose automatic plastic extrusion blowing machine.

[0103] As a specific embodiment of the present invention, the No. 1 connecting rod 49 is fixed with a No. 2 plate body 492 , and a spring 493 is fixed between the No. 2 plate body 492 and the mold 46 .

[0104] The No. 2 plate body 492 fixed to the No. 1 connecting rod 49 cooperates with the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com