Energy-saving linear bottle blowing machine

A bottle blowing machine, linear technology, applied in the field of linear bottle blowing machines, can solve the problems of limited flexibility of screw use, complex structure and action, unfavorable work efficiency, etc., to improve overall work efficiency, simple action and structure, The effect of enhancing the flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

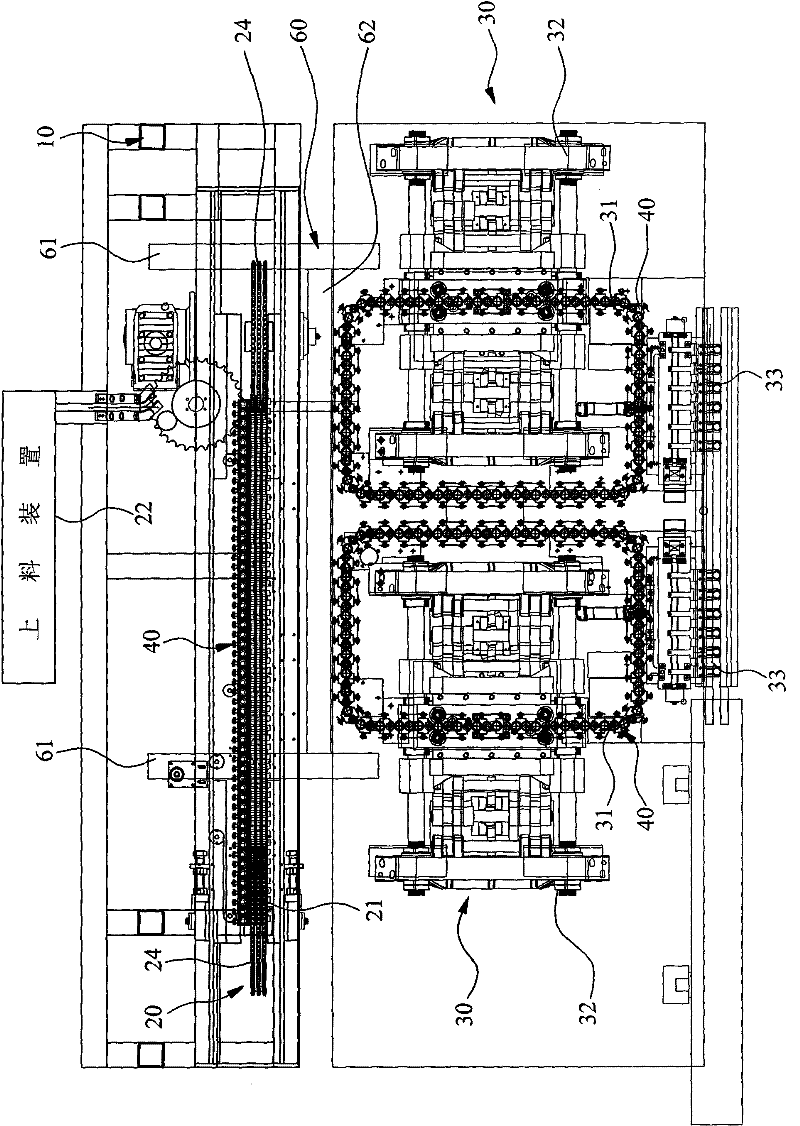

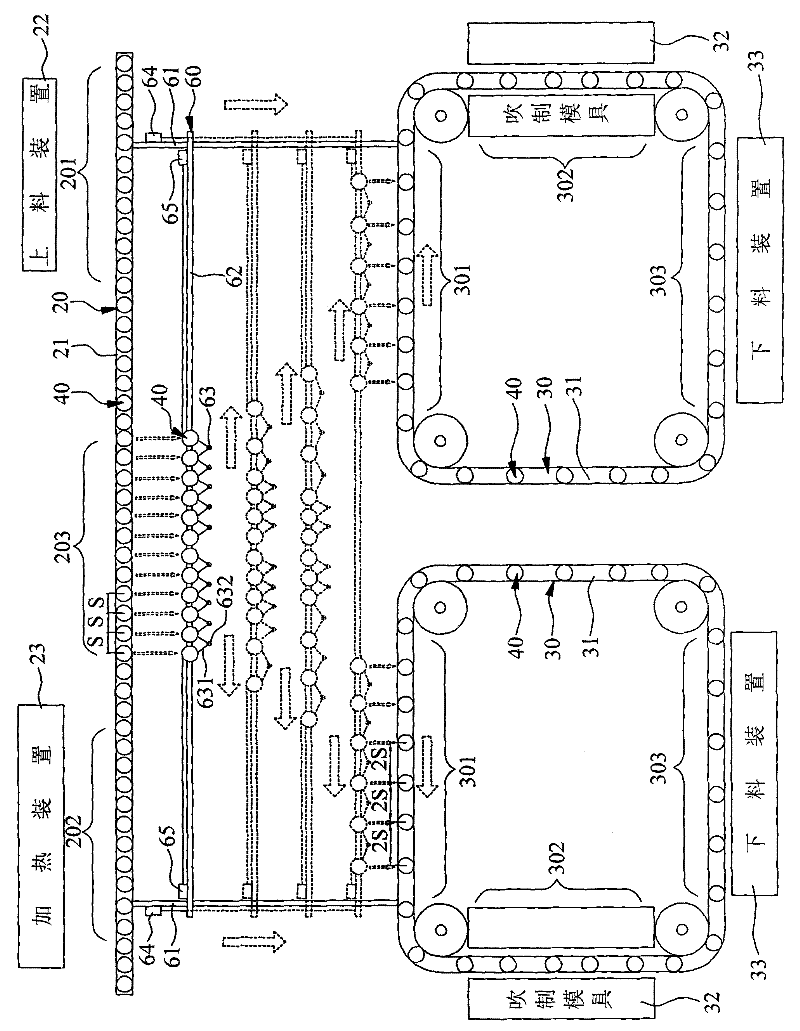

[0065] Please refer to Figure 1 to Figure 12 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a frame 10, on which a heating module 20, a blowing module 30, a preform seat 40, and an ejection mechanism are arranged. 50 and embryo transfer device 60.

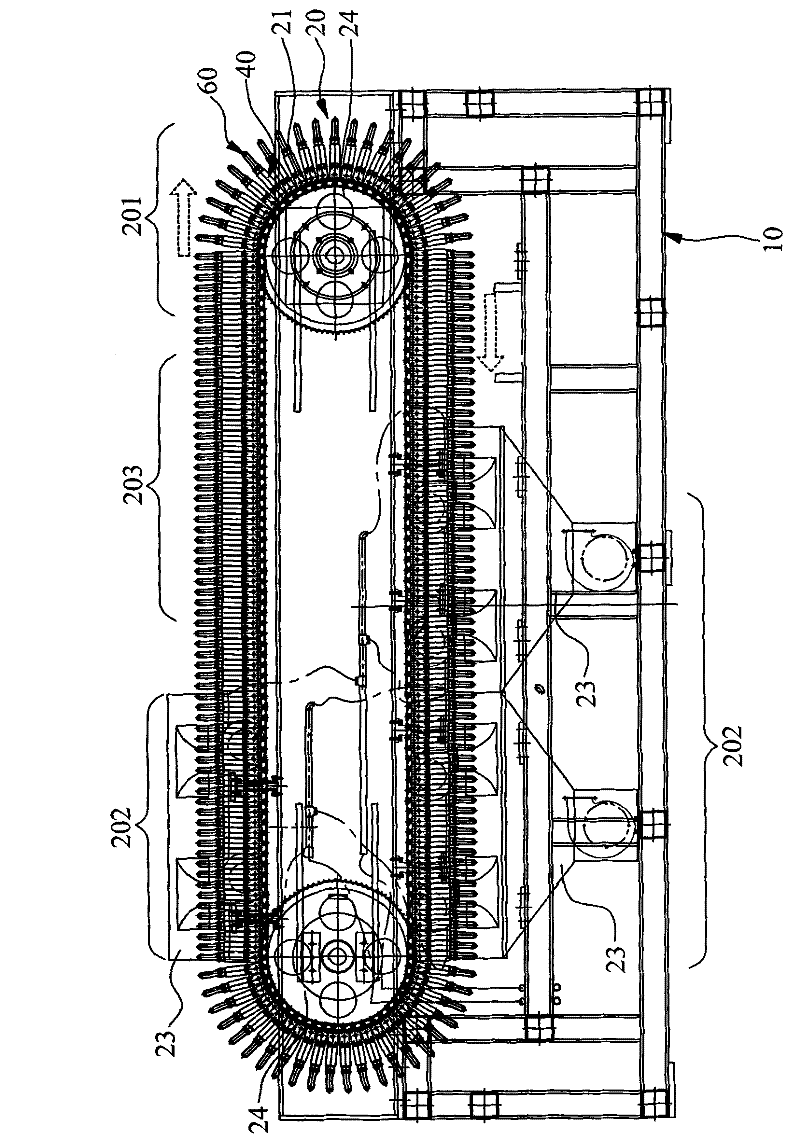

[0066] Among them, such as image 3 As shown, the heating module 20 is used to transfer the preform 70 and heat the preform 70 before blowing, which includes a heating transmission chain 21 , a feeding device 22 and a heating device 23 . A plurality of the aforementioned preform holders 40 are tightly arranged on the heating transmission chain 21, and the preform holders 40 are used for accommodating the preforms 70, and each preform holder 40 is equipped with a preform 70. The embryo bases 40 are closely arranged, so that more preforms 70 can be heated at one time, which is beneficial to make full use of heat sources, save energy and improve efficiency. The heating trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com