Blow molding device convenient to fix and for plastic bucket production and using method

A technology of blow molding device and plastic barrel, applied in the field of plastic barrel blow molding, which can solve the problems of large limitations, inconvenient use, and low efficiency, and achieve the effects of convenient disassembly, saving time, and improving blow molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

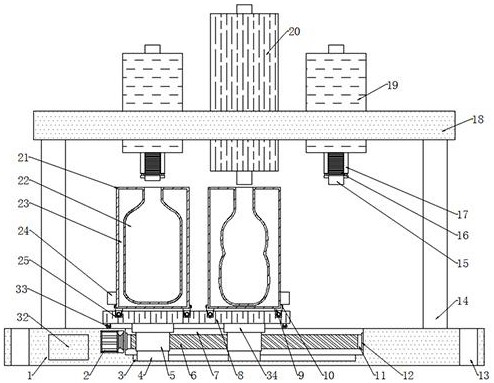

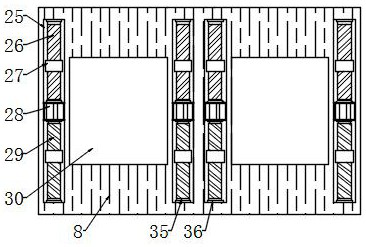

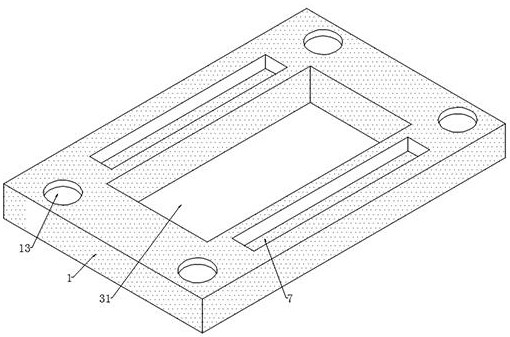

[0030] see Figure 1-3 , the present invention provides the following technical solutions: a convenient fixed blow molding device for the production of plastic barrels, including a mounting plate 1, the top of the mounting plate 1 is provided with a first groove 7, the first groove 7 The side of the inner wall is fixedly connected with a first bearing 12, and a first rotating shaft 11 is pierced in the first bearing 12, and one end of the first rotating shaft 11 is fixedly connected with a first threaded column 6, and the first rotating shaft 11 One end passes through the first bearing 12 and is fixedly connected with the driving motor 2. The driving motor 2 works and can drive the first threaded column 6 to rotate, and then the first threaded sleeve 5 can drive the movable plate 8 to move left and right, so as to realize the blow molding and The parison feeding cycle is carried out, which saves time and improves blow molding efficiency.

[0031] The surface of the first thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com