Distribution board based on modular structures

A modular structure and switchboard technology, applied in substation/distribution device housing, electrical components, substation/switch layout details, etc., can solve the problems of high maintenance cost, inconvenient use, short service life, etc., to reduce maintenance cost, Effects of improving work efficiency and preventing rust and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

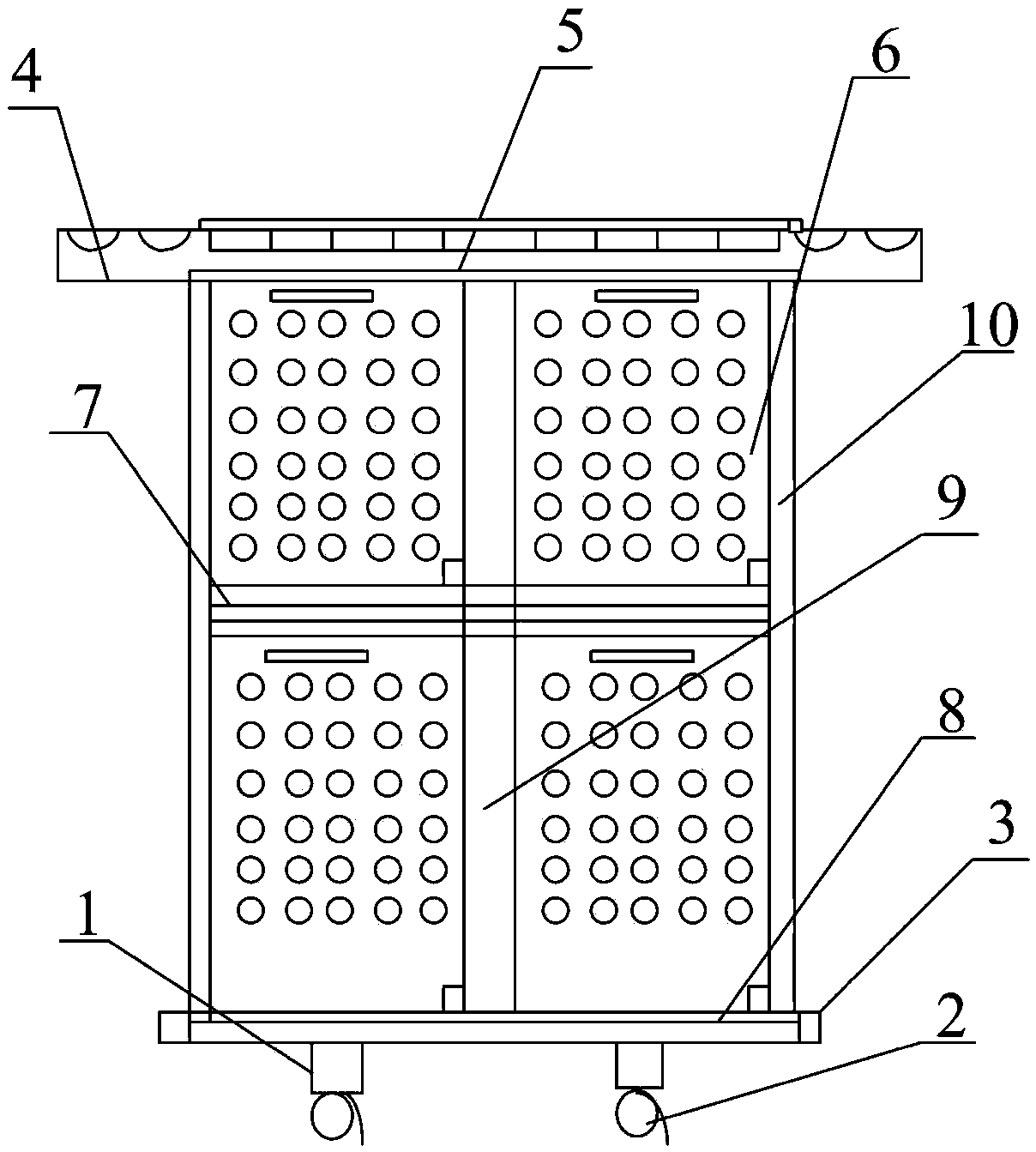

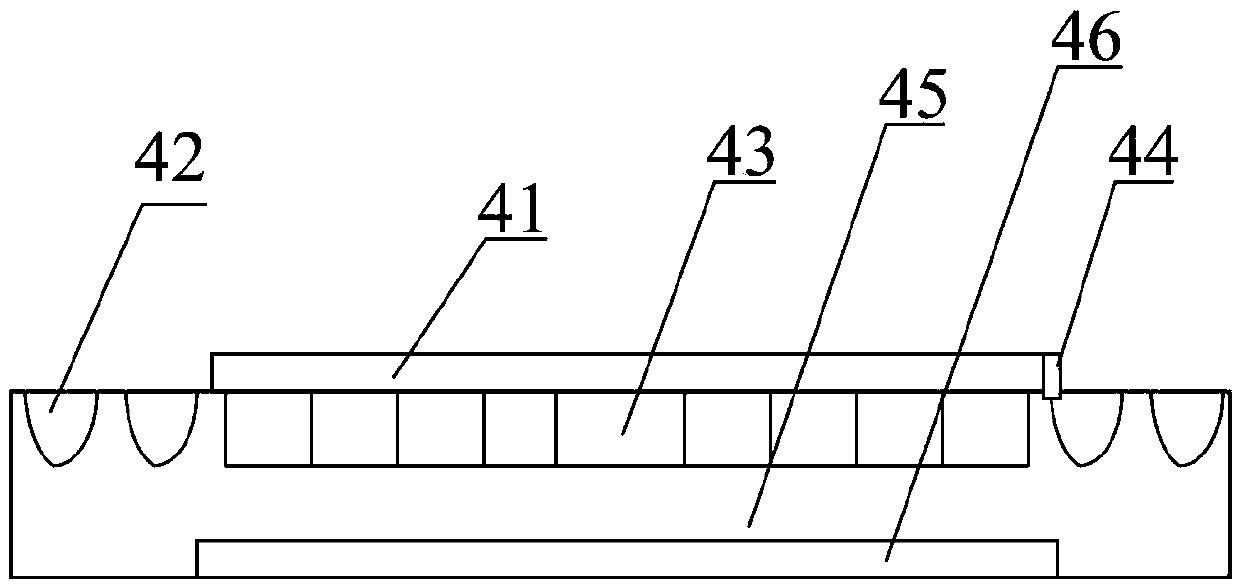

[0025] as attached figure 1 to attach image 3 shown

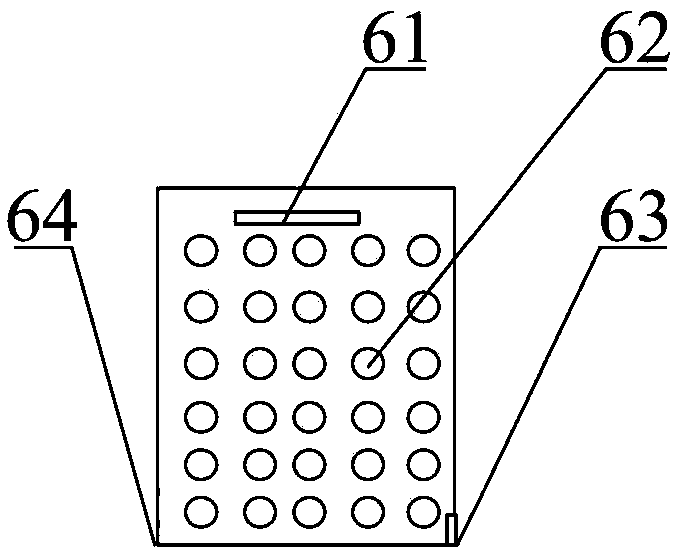

[0026] The present invention provides a switchboard based on a modular structure, including a leg 1, a universal wheel 2, a base 3, a roof structure 4, an upper rail 5, a module structure 6, a middle rail 7, a lower rail 8, a longitudinal beam 9 and a frame 10. The said leg 1 is installed on the upper part of the universal wheel 2; the said base 3 is arranged on the lower part of the lower track 8; the said top plate structure 4 is arranged on the upper part of the module structure 6; and the middle position of the module structure 6; the middle track 7 is arranged at the combination position of the upper module structure 6 and the lower module structure 6; the longitudinal beam 9 is arranged at the longitudinal middle position of the module structure 6; the described The frame 10 is arranged on both sides of the module structure 6; the module structure 6 includes a hooking groove 61, a plate mounting hole 62, a label ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com