Method for applying die-cuts to surfaces and testing methods therefor

A technology of die-cutting, die-cutting, applied in the direction of bonding methods, household components, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

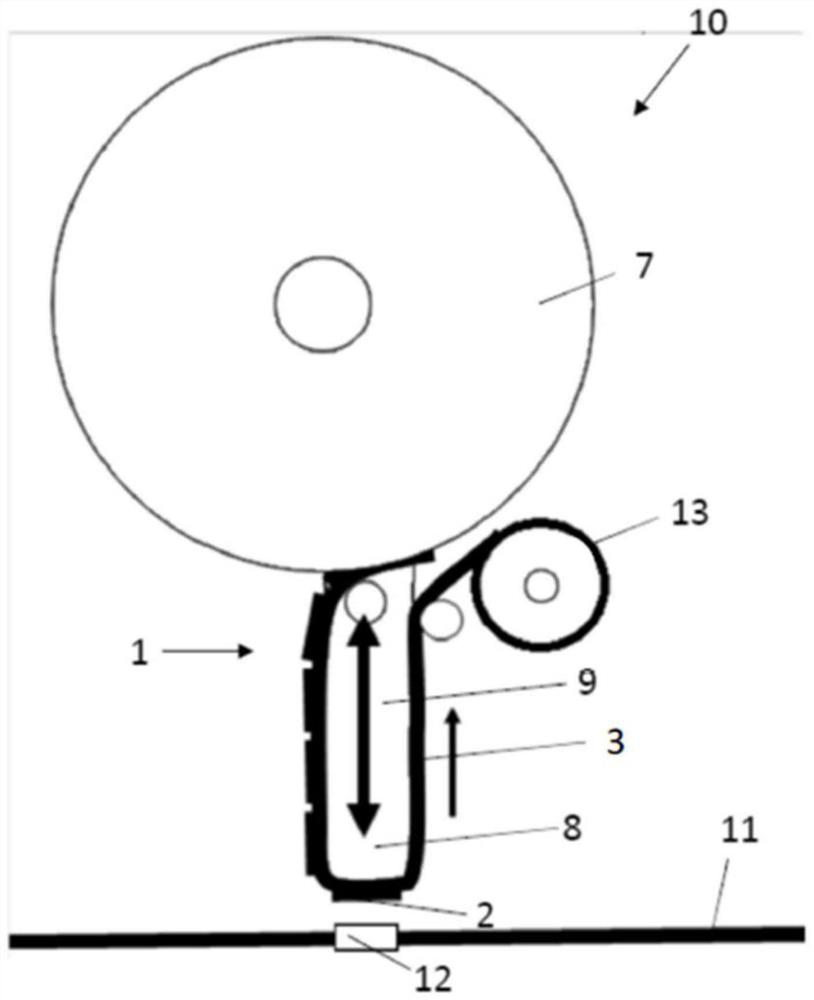

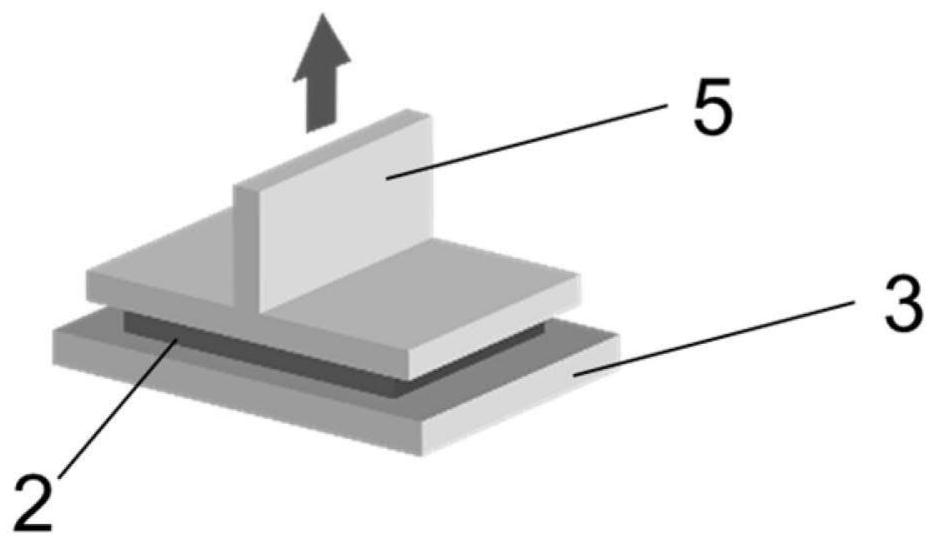

[0029] In a preferred embodiment of the method, the applicator comprises:

[0030] (i) a punching machine having a punch,

[0031] and

[0032] (iii) pad take-up rolls,

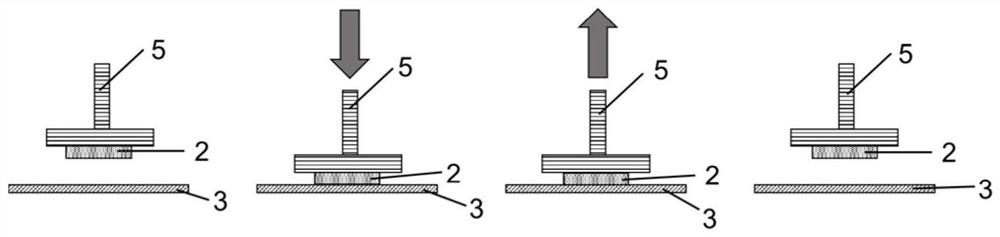

[0033] Wherein, in this method, the die-cutting belt runs on the punch of the punching machine, when one of the die-cut parts is on the punching head, the die-cutting belt is stopped, and then the punching machine sticks the die-cutting parts in an up and down motion. attached to the surface.

[0034] If the ratio of the pull-off force of the die-cut from the backing layer in z-direction to the pull-off force of the die-cut from said surface in z-direction is at most 0.15, preferably at most 0.12 and more particularly at most 0.10, then is particularly beneficial.

[0035] The method of the invention is suitable for both manual and automated application of die-cuts. In the particular case of automated application, the method according to the invention brings with it great advantages, since here special e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com