Shaping signal control method with high clock cycle fault tolerance

A technology of clock cycle and signal shaping, which is applied in the field of signal shaping control with high clock cycle error tolerance of camera voice coil motor actuators. It can solve problems such as clock cycle errors and achieve great robustness and fast stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention provides a shaping signal control method with high clock cycle error tolerance rate, which is used to control voice coil motor actuators. It has high fault tolerance for errors between the clock cycle and the voice coil motor natural oscillation cycle, and can be widely used in other In large-scale integrated circuits, especially in second-order underdamped system control chips. The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

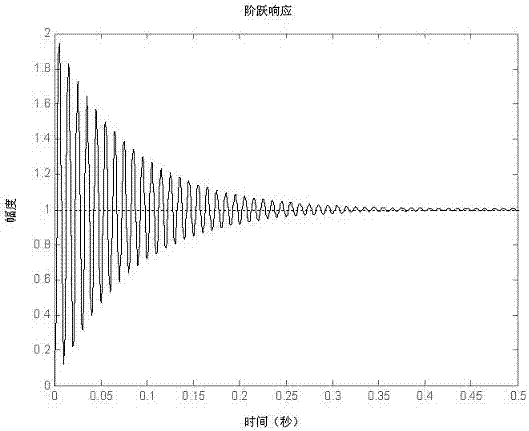

[0060] figure 1 It is the response of a common voice coil drive motor (VCM) when the input signal is a unit step signal. It can be seen from the figure that the motor system is an underdamped oscillation system, and the damped oscillation coefficient in this model is 0.02. If the oscillation amplitude of the motor is reduced to less than 5% of the final rising amplitude, the motor is considered to be basically stable. From figure 1 It can be seen that when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com