Cascade waveguide-based double-step structure end face coupler

An end-face coupling, double-step technology, used in optical waveguides, instruments, light guides, etc., can solve the problems of long size, small error tolerance, and difficult processing, and achieve small size, high error tolerance, and efficient coupling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

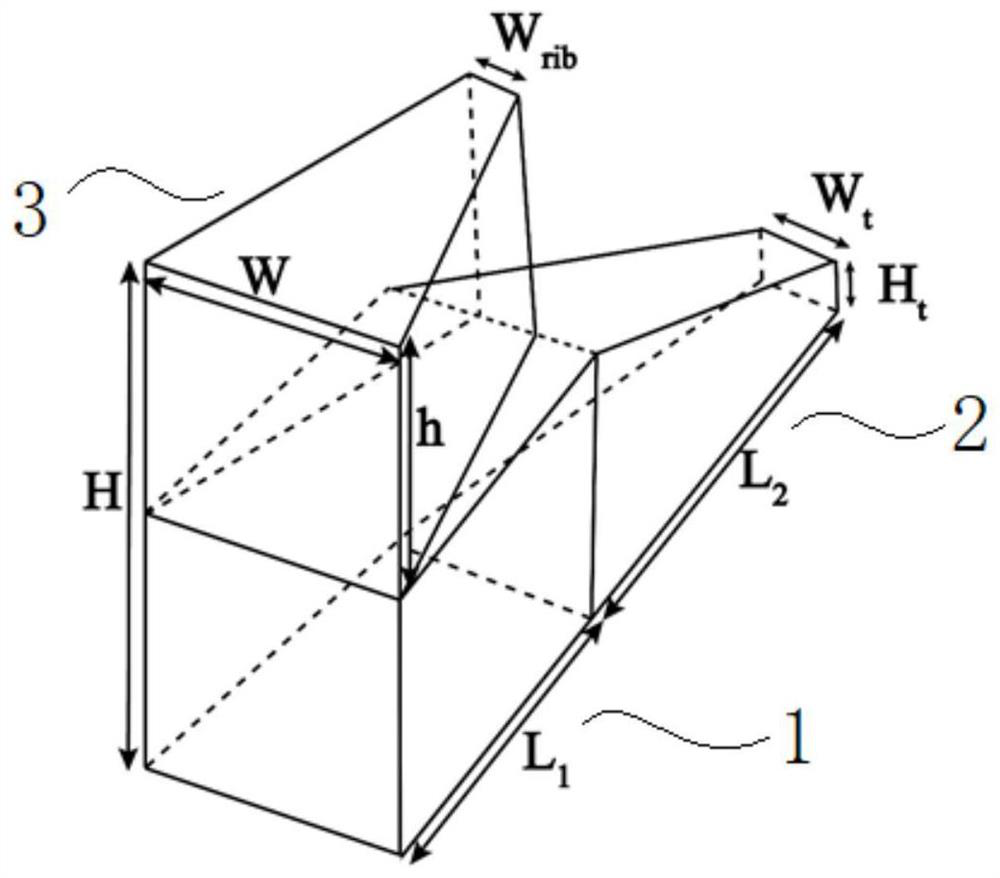

[0030] In order to better understand the technical solution, the method of the present invention will be described in detail below with reference to the accompanying drawings. As used herein, the term "coupled" refers to any connection, coupling, link, etc., and "optically coupled" refers to a coupling such that light is passed from one element to another. Such "coupling" devices do not have to be directly connected to one another, but may be separated by intervening components or devices that manipulate or modify such signals. Likewise, the term "direct coupling" or "direct optical coupling" as used herein refers to any optical connection that allows light to be passed from one element to another without intervening devices such as optical fibers.

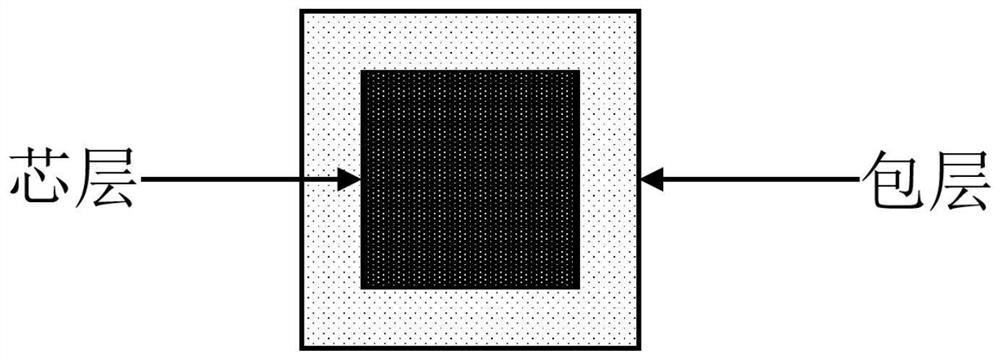

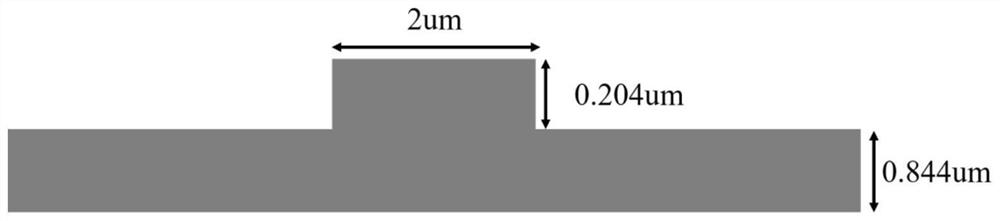

[0031] The size of the AWG output waveguide involved in the present invention is 4.5×4.5 μm, while the waveguide coupling layer of the edge-entry detector is a single-mode ridge waveguide with a size of 2×1.048 μm. There is a larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com