Driving speed change device for agricultural machinery

A technology of speed change device and agricultural machinery, which is applied in the direction of agricultural machinery and implements, transmission device, transmission device parts, etc., can solve the problems such as delay, deformation, even tightness and slippage of driving gearbox.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

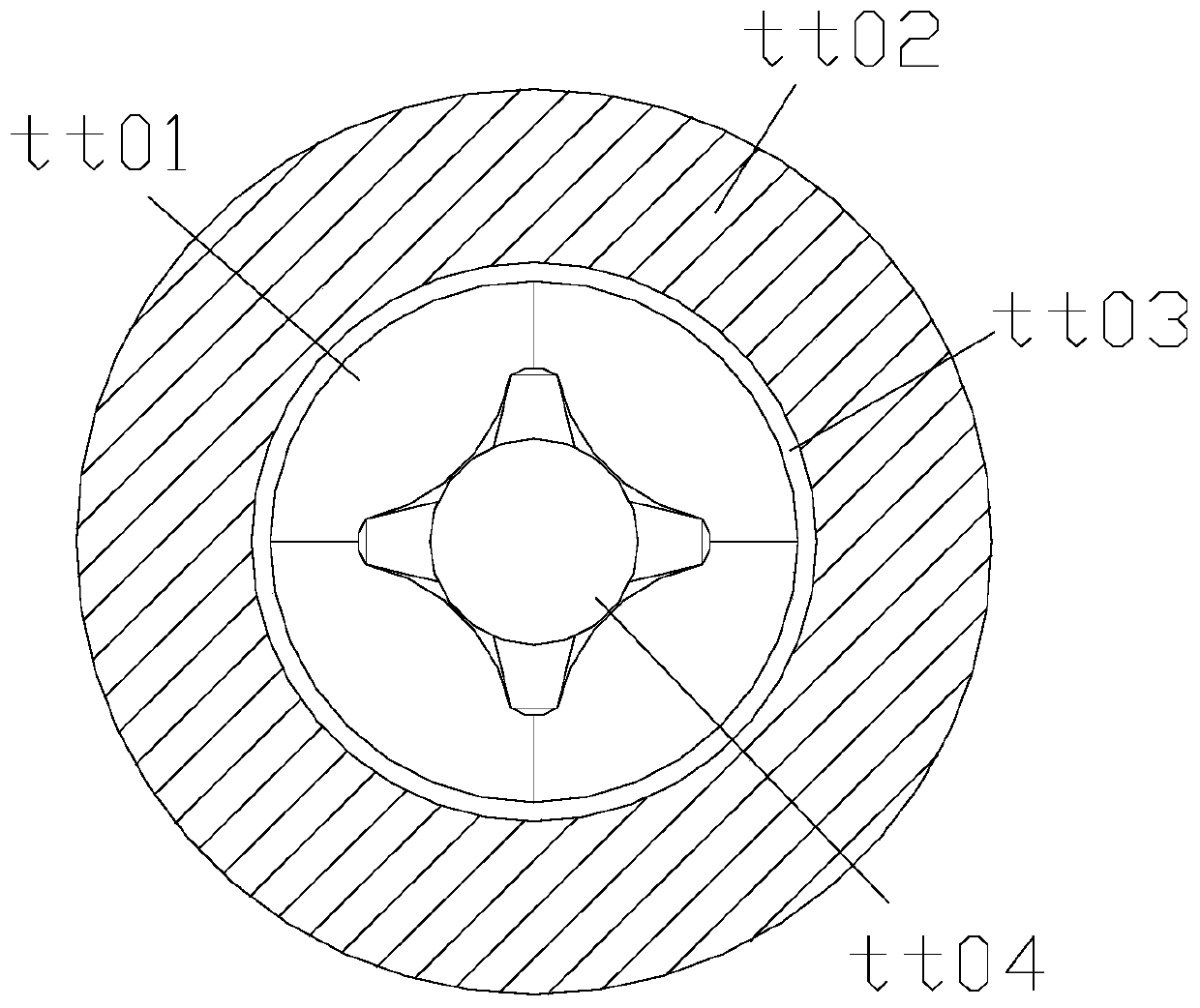

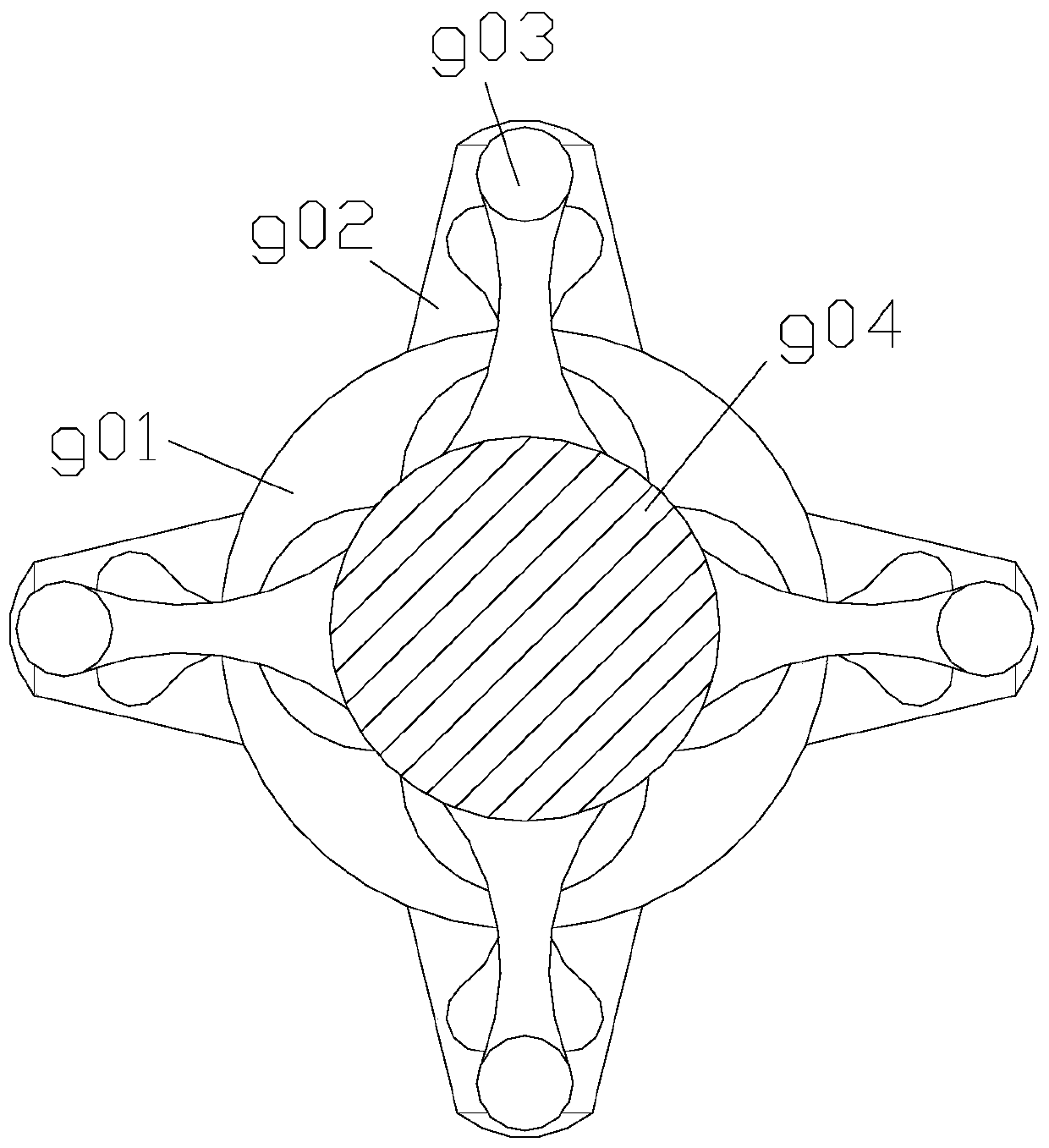

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The invention provides a drive transmission device for agricultural machinery, the structure of which includes a push rod a1a, a receiving barrel a2a, a harvesting head a3a, a guide body a4a, a booster wheel a5a, a bottom fixing plate a6a, and a drive gearbox a7a.

[0034] The push rod a1a is welded on the outer surface of the bottom solid plate a6a, the receiving tube a2a is installed on the upper surface of the bottom solid plate a6a, the harvesting head a3a is connected with the rotating body a4a, and the booster wheel a5a runs through the Inside the bottom fixing plate a6a, the drive gearbox a7a abuts against the outer surface of the guide body a4a and is movably connected.

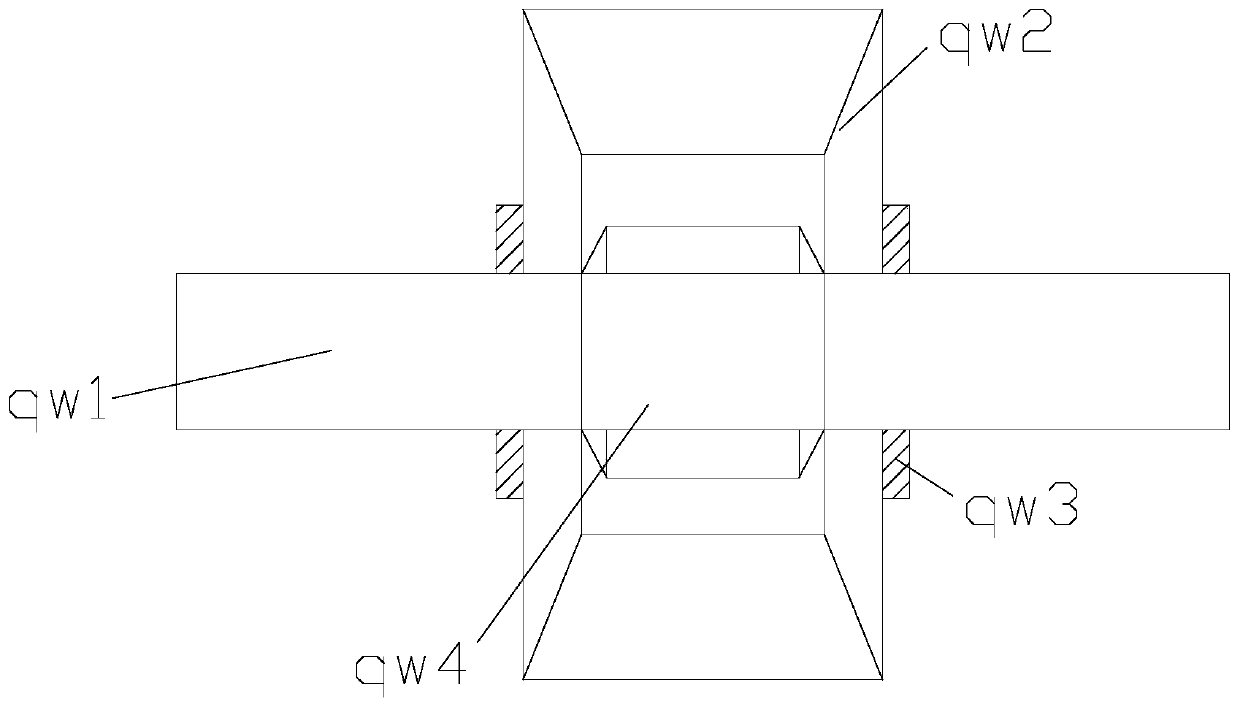

[0035] The drive gearbox a7a includes a middle rod qw1, a transfer box body qw2, an outer limit ring qw3, and a card body qw4. The middle rod qw1 is connected to the card body qw4 and is located on the same axis. The outer limit ring qw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com