Regulator

A regulator and pressure regulating valve technology, applied in the field of regulators, can solve the problems of the valve seat seat 4 falling off and easily falling off, and achieve the effects of eliminating individual differences, high-precision and reliable installation, and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

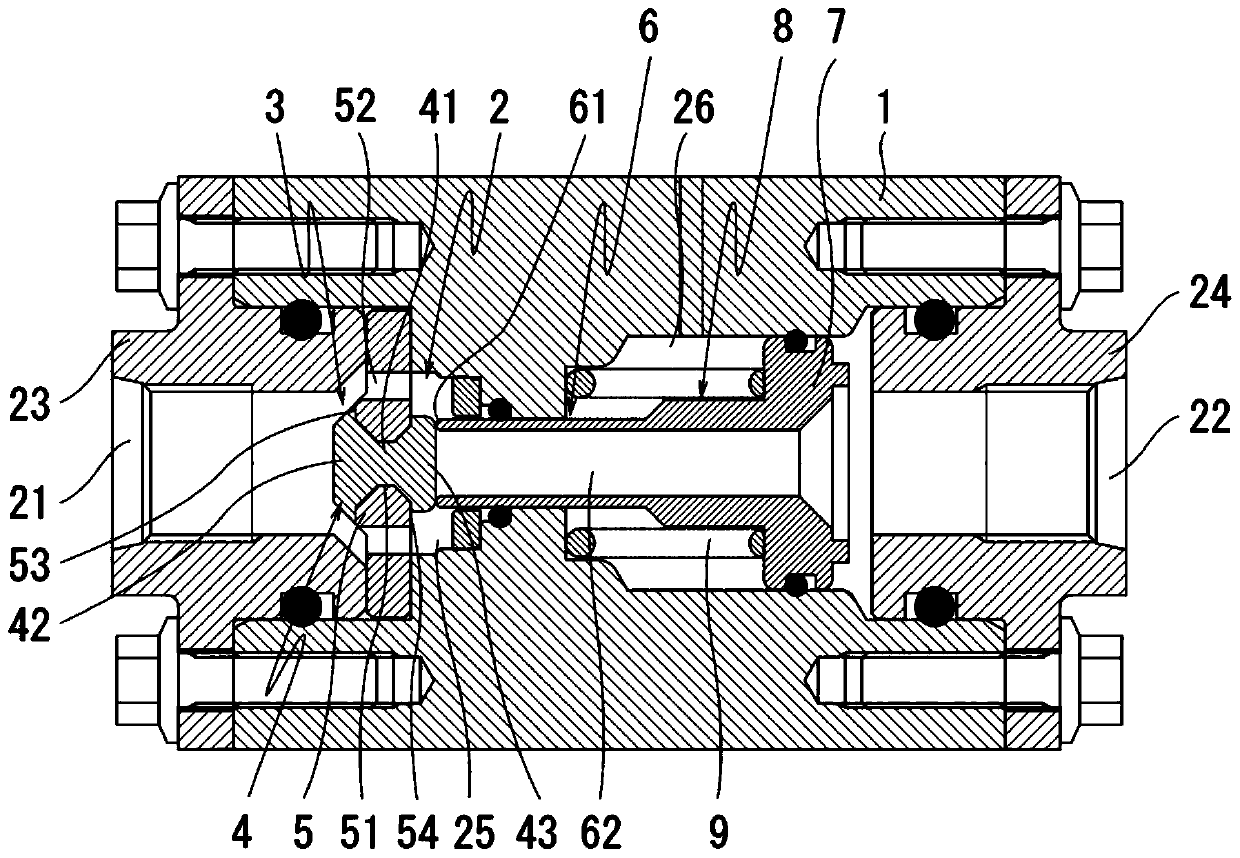

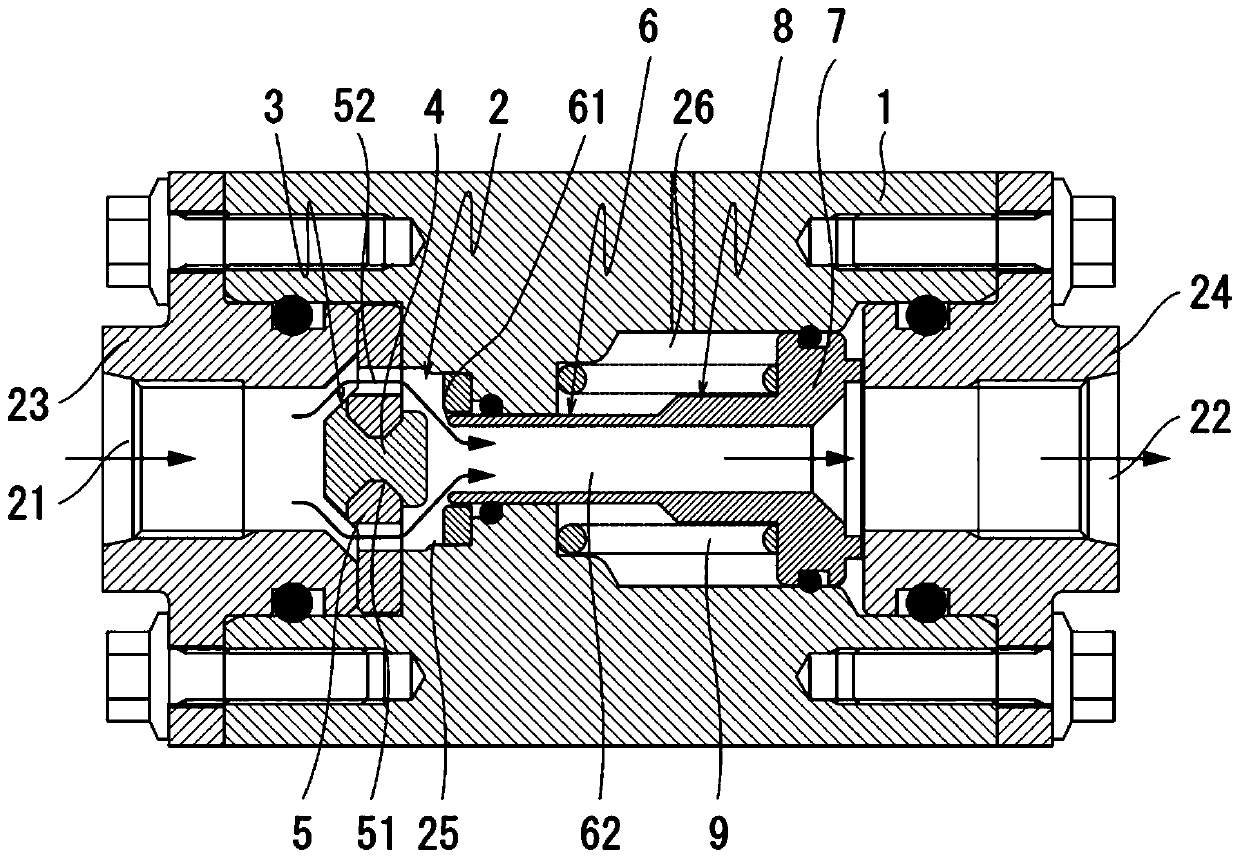

[0065] figure 1 and figure 2 A cross-sectional view showing a preferred embodiment of the present invention, the overall structure is the same as that described above Figure 7 to Figure 10 The conventional examples shown are substantially the same, and detailed descriptions of these configurations are omitted. In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned conventional example, and it demonstrates.

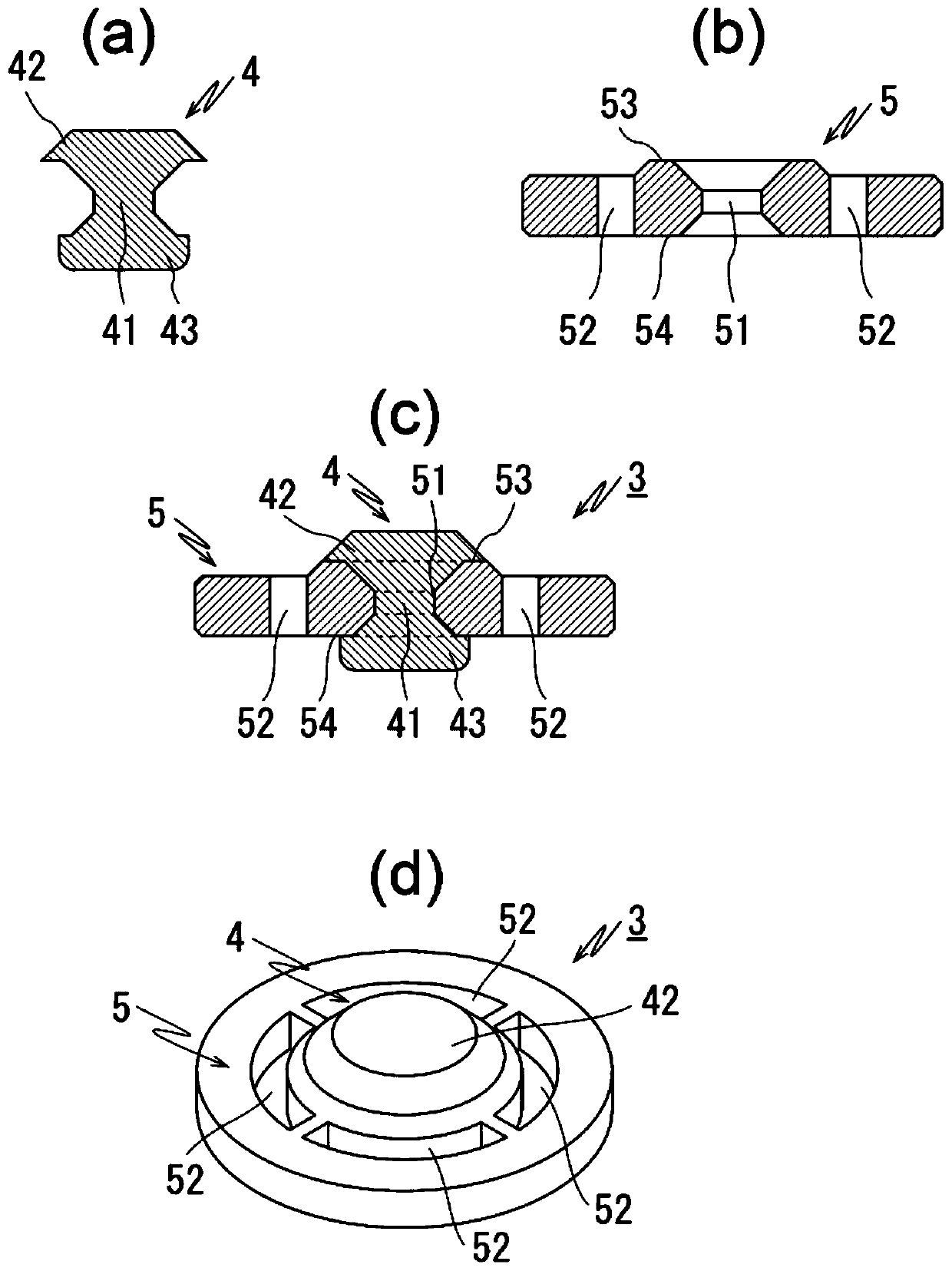

[0066] In addition, the point which is particularly different from the above-mentioned conventional example is the structure of the valve seat 3 . Such as image 3 As shown, the valve seat portion 4 of the valve seat 3 in this embodiment is composed of a shaft body 41, a locking body 42, and a valve seat portion main body 43. The shaft body 41 is inserted into a holding portion 51, and the holding portion 51 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com