Magnetic-head supporting element mfg. method

A technology for supporting components and magnetic heads, which is applied in the direction of supporting the head, the hydrodynamic spacing of the head, the configuration/installation of the recording head, etc., and can solve problems such as FPC peeling, FPC performance degradation, mechanical damage to load beams or flexible components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Detailed Description of Preferred Embodiments

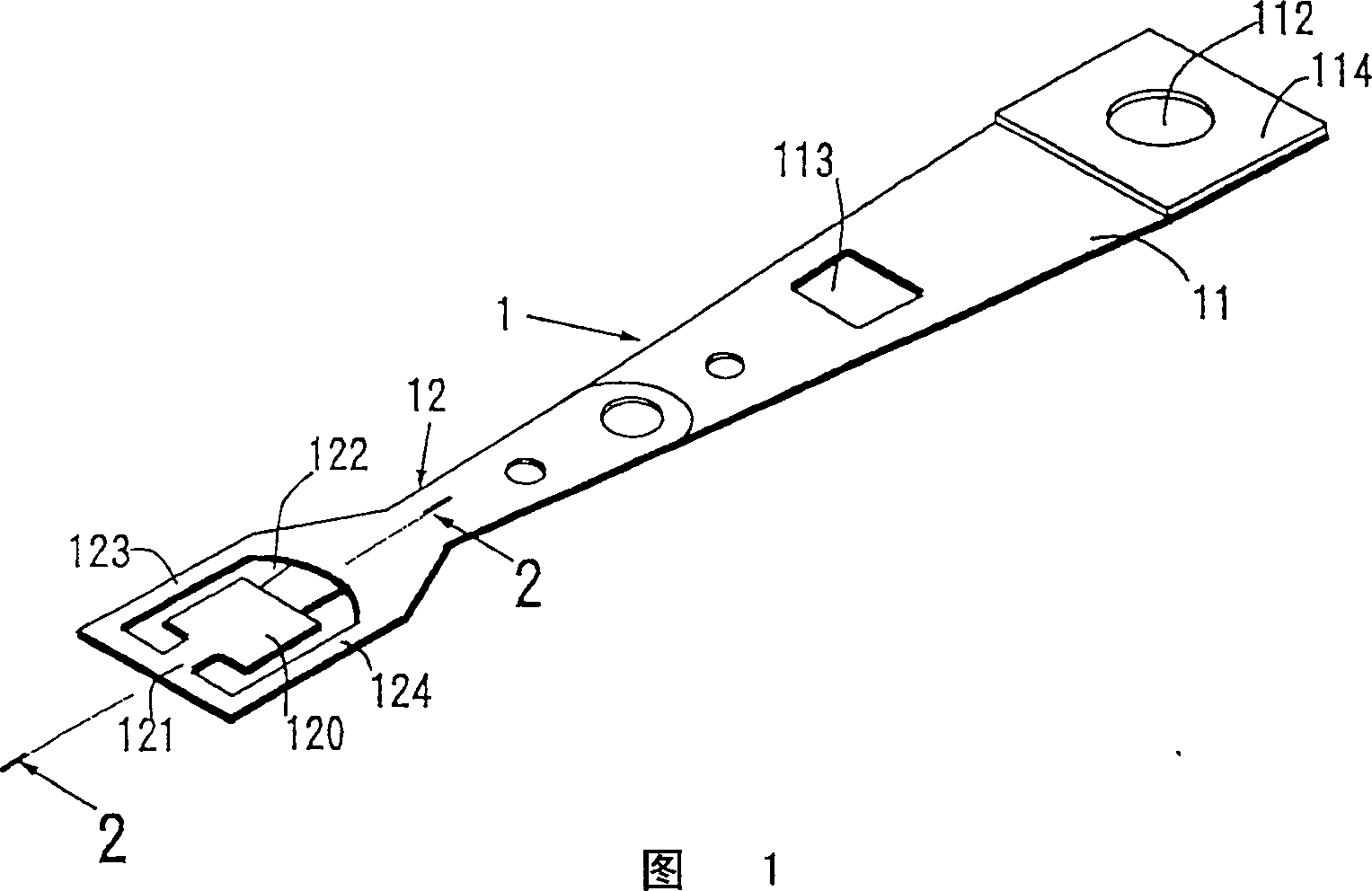

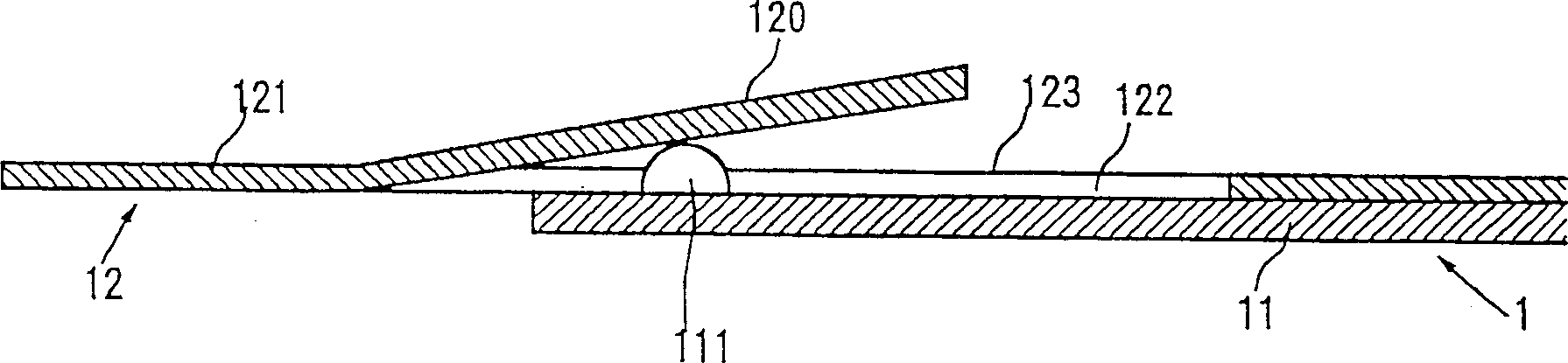

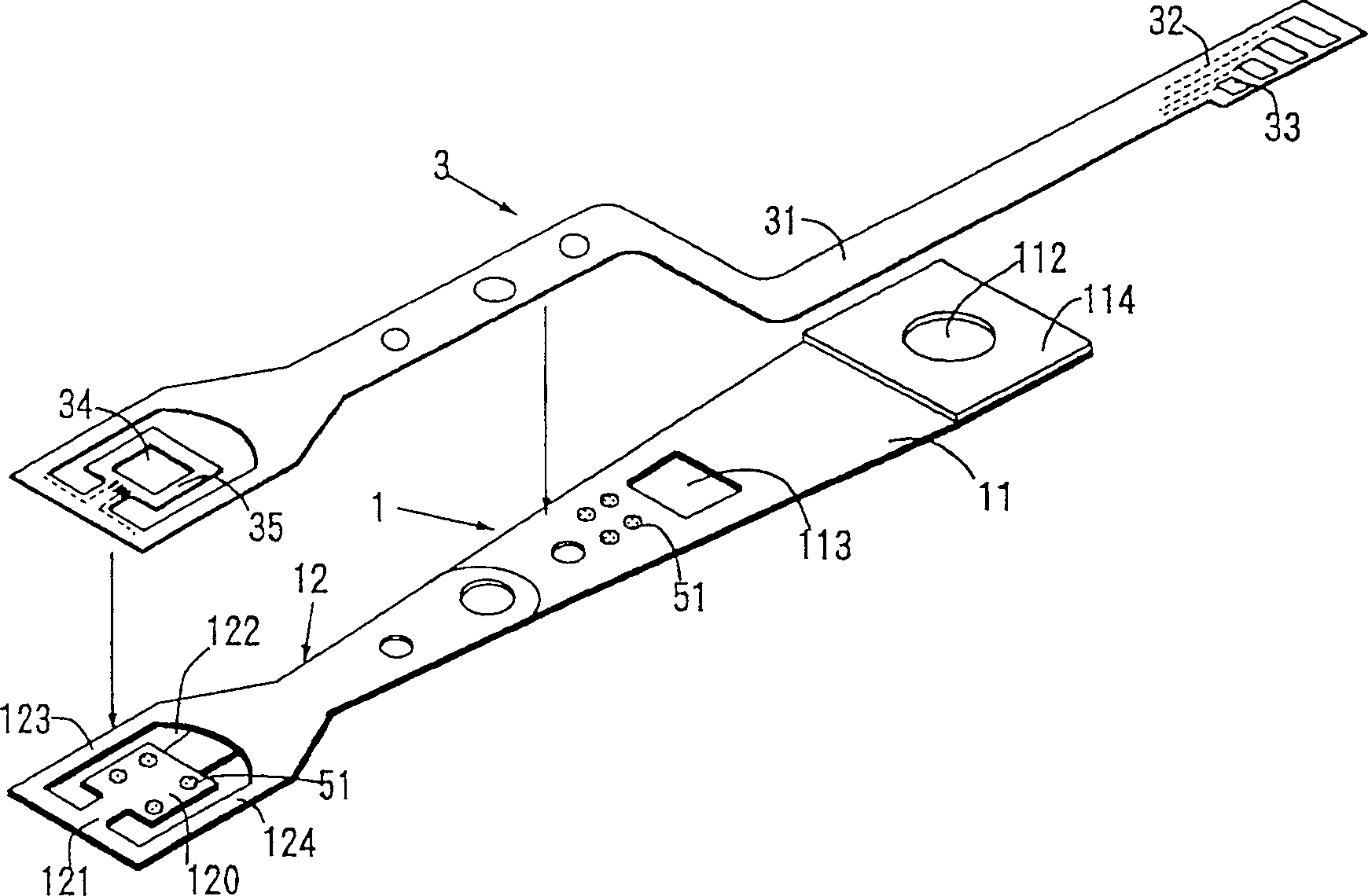

[0031] Figure 1 is a perspective view of a magnetic head supporting member constituting an object to which the manufacturing method of the present invention is applied, and figure 2 is an enlarged partial cross-sectional view taken along line 2-2 of FIG. 1 .

[0032] A magnetic head supporting element 1 includes a load beam 11 and a flexible element 12 . The load beam 11 is integrally formed in the shape of a flat plate, and does not undergo bending associated with an inclination angle. The magnetic head supporting member 1 is provided by the magnetic head supporting member manufacturer in the state of the flat plate shape.

[0033] The load beam 11 is provided with a protruding portion 111 near a free end on an axis in the longitudinal direction passing through the center of the end (see figure 2 ). The load beam 11 is provided with a base portion 114 (see figure 2 ), and a positioning hole 112 is provided substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com