Cab for work machine

A work machine and cab technology, applied in the field of work machine cabs, can solve problems such as difficulty in ensuring vertical and horizontal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0050] (1) Overall structure

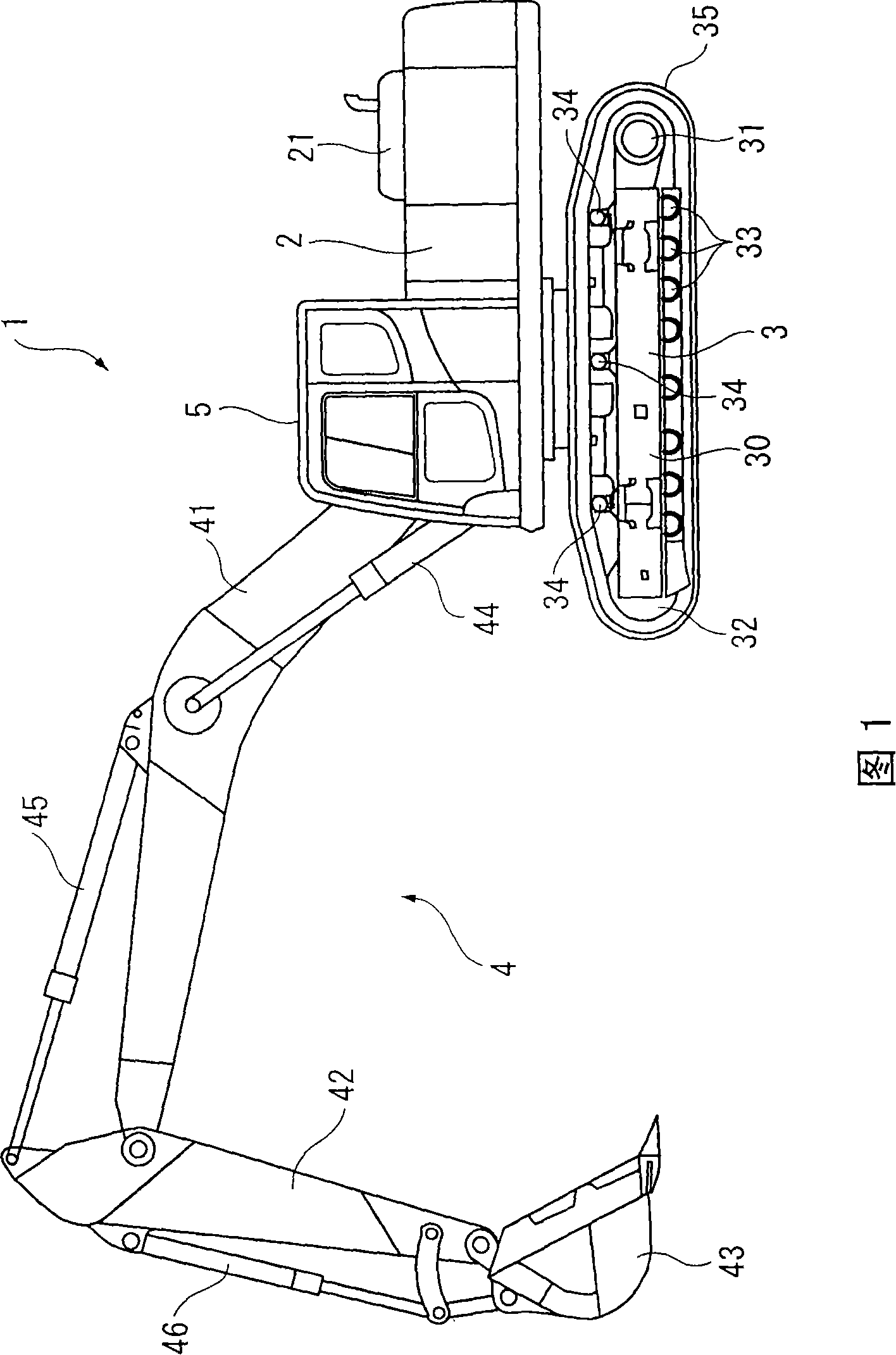

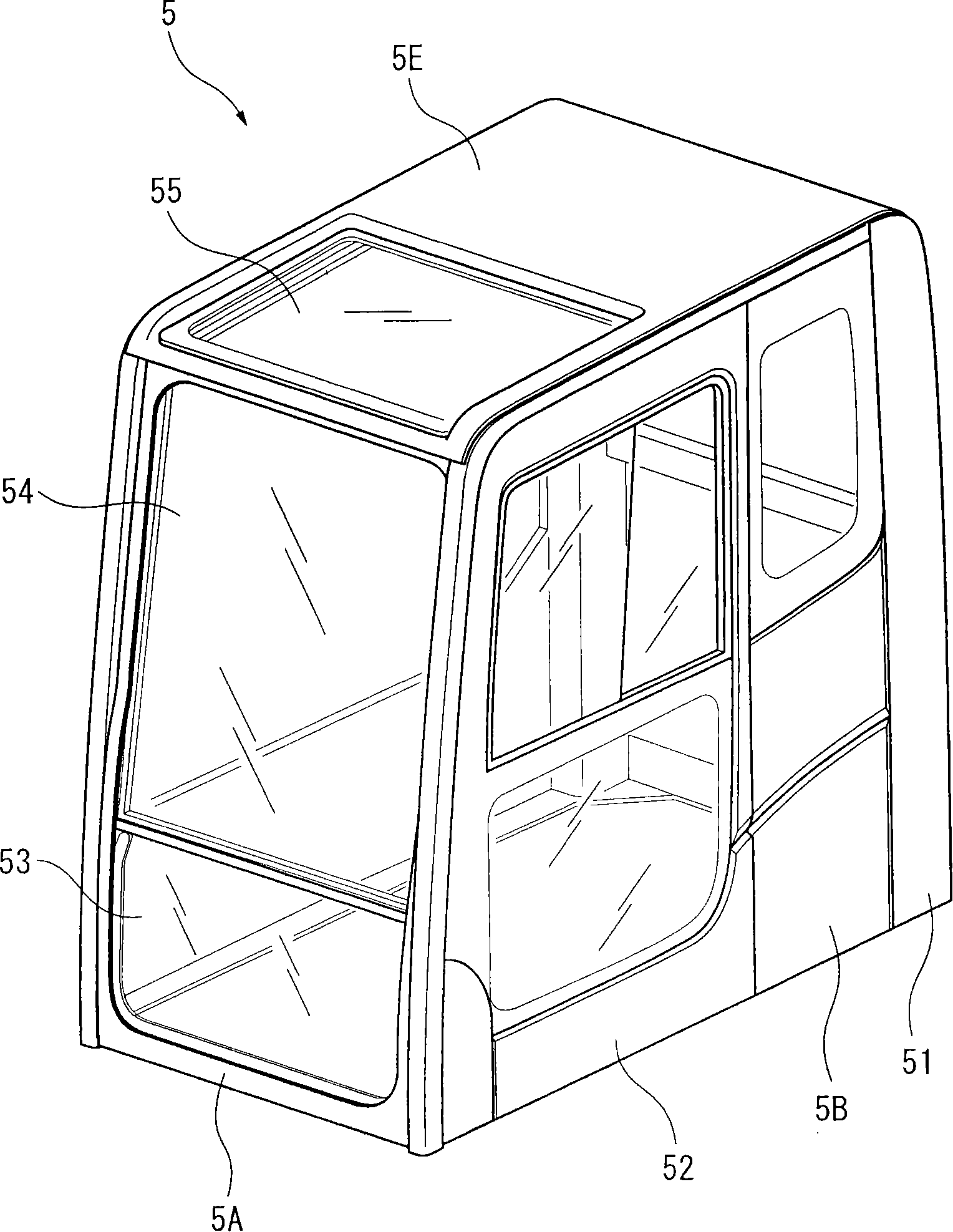

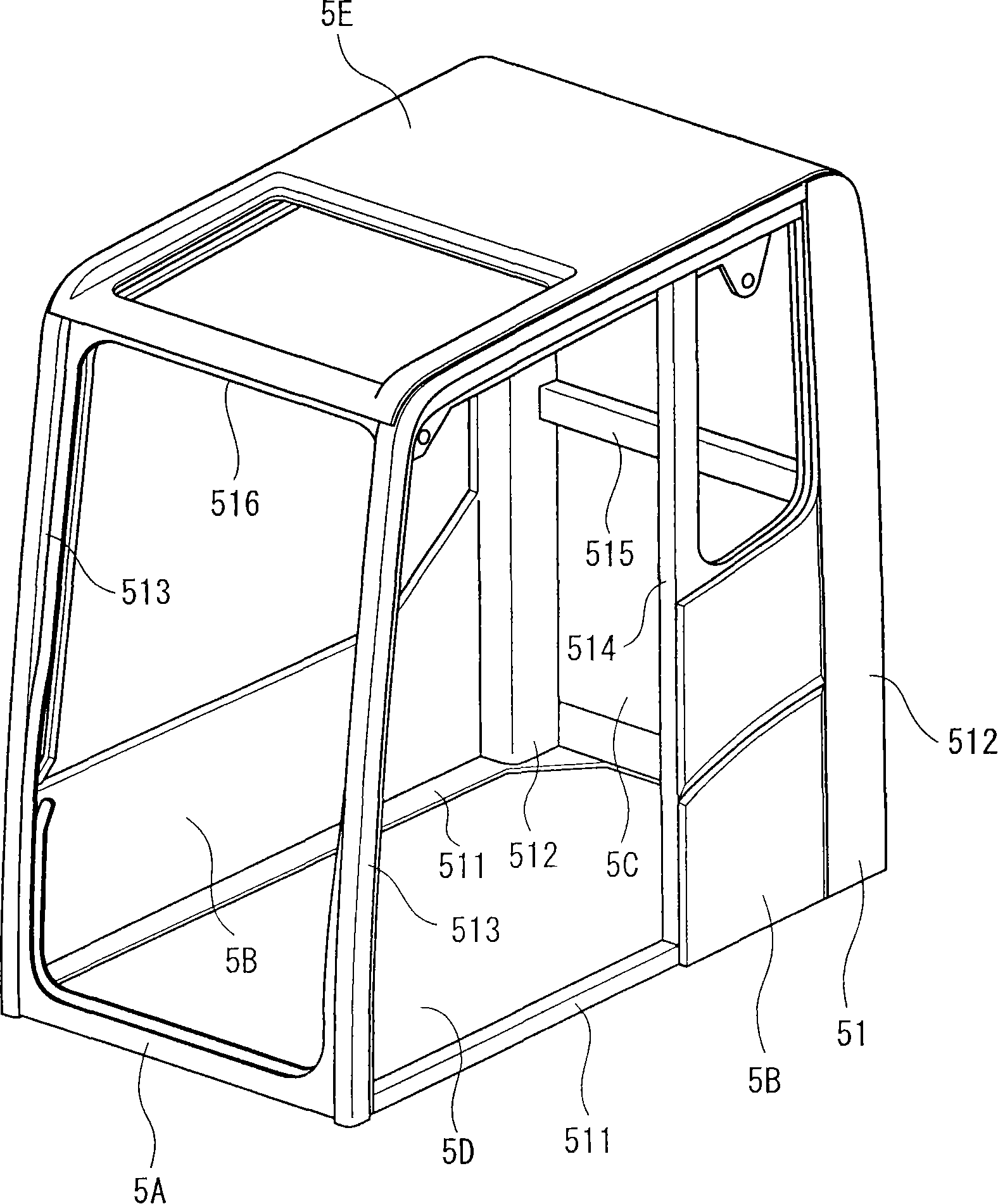

[0051] FIG. 1 shows a hydraulic excavator 1 as a work machine according to an embodiment of the present invention. This hydraulic excavator 1 is configured to include a vehicle body 2 , a traveling device 3 , a work machine 4 , and a cab 5 for the work machine.

[0052] The vehicle main body 2 is equipped with a work machine 4 , a work machine cab 5 , an engine 21 , and a hydraulic circuit driven by the engine 21 (not shown in the figure), the work machine 4 is provided on the front side of the vehicle, and the work machine is provided approximately in the center of the vehicle. The machine cab 5 is provided with an engine 21 on the rear side of the vehicle.

[0053]The traveling device 3 is provided at the lower portion of the vehicle body 2, and supports the vehicle body 2 in the horizontal direction to ensure its free rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com