Injection product defect classification method based on machine learning

A technology for classification of injection molding products and defects, which is applied to instruments, computer parts, calculations, etc., can solve problems such as single classification, inability to classify, increase time cost, etc., and achieve effective classification, improve accuracy, and enhance connectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

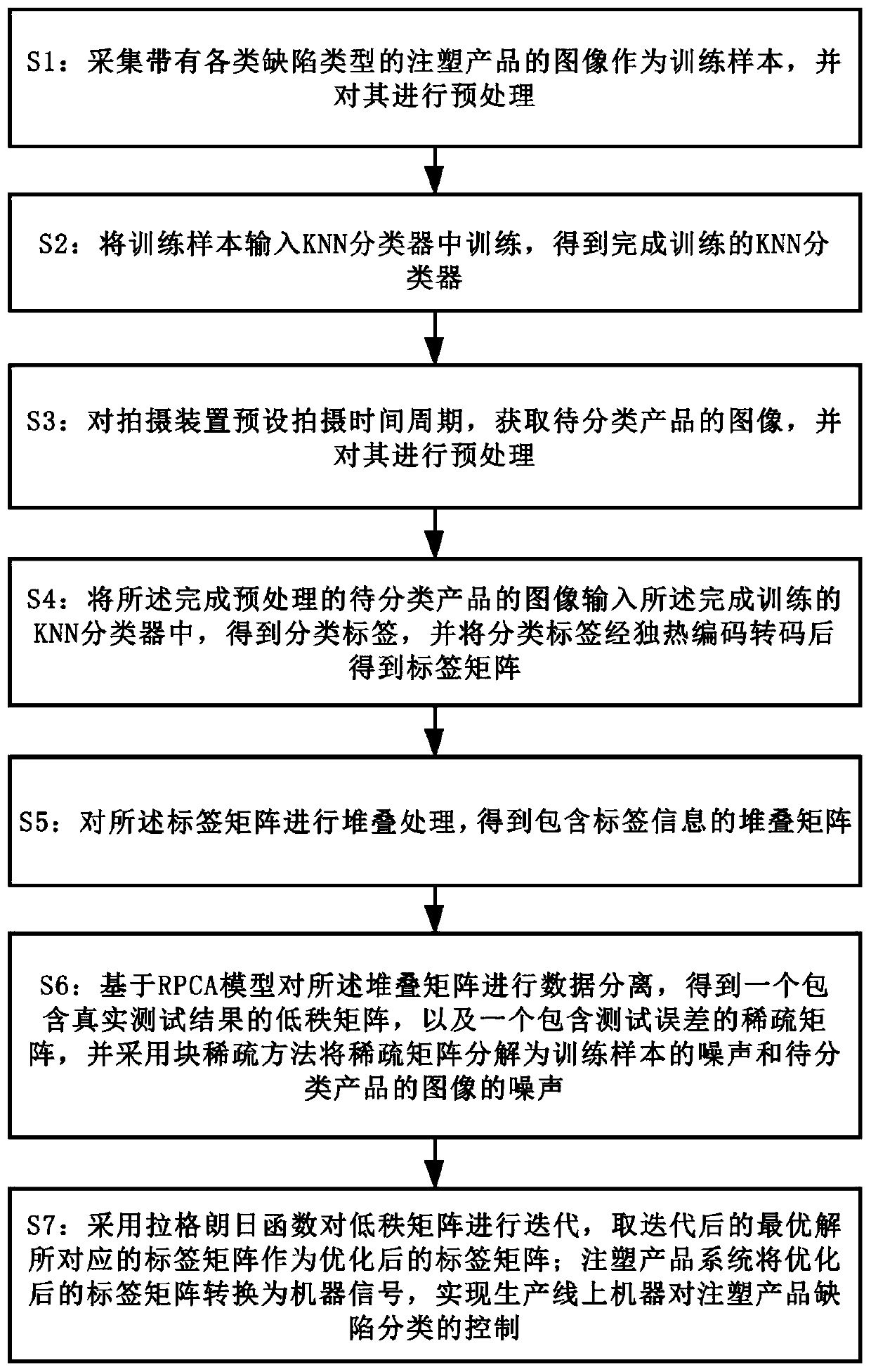

[0040] This embodiment proposes a method for classifying defects of injection molding products based on machine learning, such as figure 1 As shown, it is a flow chart of a method for classifying defects of injection molded products based on machine learning in this embodiment.

[0041] In the method for classifying defects of injection molding products based on machine learning proposed in this embodiment, the following steps are included:

[0042] S1: Collect images of injection molded products with various types of defects as training samples and preprocess them.

[0043] In this step, the steps of preprocessing the training samples include:

[0044] S11: Manually label the images [t1, t2, ..., tn] in the training samples to obtain an image label set [s1, s2, ..., sn];

[0045] S12: Grayscale the images [t1, t2, ..., tn] in the training samples, and perform parameter transformation on the two-dimensional domain, and the transformation formula is as follows:

[0046] tn'=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com