Automobile sun shield assembly jig

A technology for automobile sun visors and sun visors, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as low efficiency and complex structure, and achieve the effects of convenient operation, high assembly efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

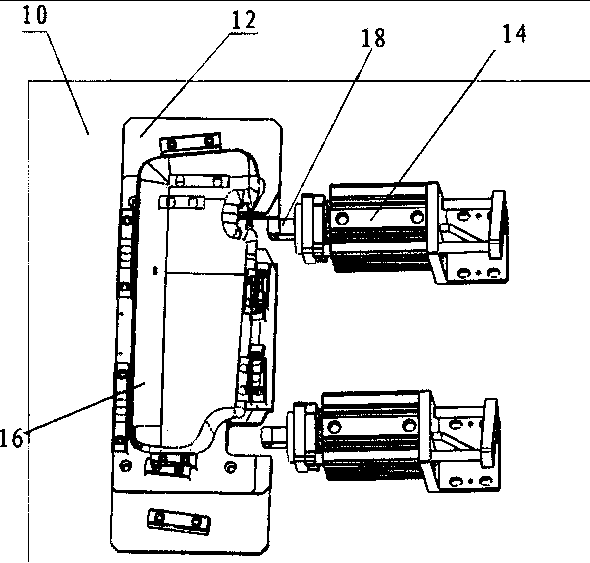

[0010] see figure 1 A kind of automobile sun visor assembling jig shown comprises a horizontal workbench 10, on which a sun visor carrier plate 12 and a power unit 14 for assembling the sun visor are oppositely arranged on the workbench 10, and the carrier plate 10 is provided with There is a groove 16 corresponding to the shape of the sun visor.

[0011] The power unit 14 is two air cylinders arranged at intervals, and an extruding block 18 is arranged on the telescopic rods of the air cylinders.

[0012] During use, place the plate-shaped part and the mounting part of the sun visor in the groove 16 on the carrier plate 10. After starting the power unit 14, the mounting part and the plate-shaped part are tightly squeezed into one body. Only the user is required to operate The assembly of the sun visor can be completed by placing the plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap