Method for operating an auxiliary system of a motor vehicle

A technology for auxiliary systems and motor vehicles, which is applied in the field of auxiliary systems and can solve problems such as increased weight and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

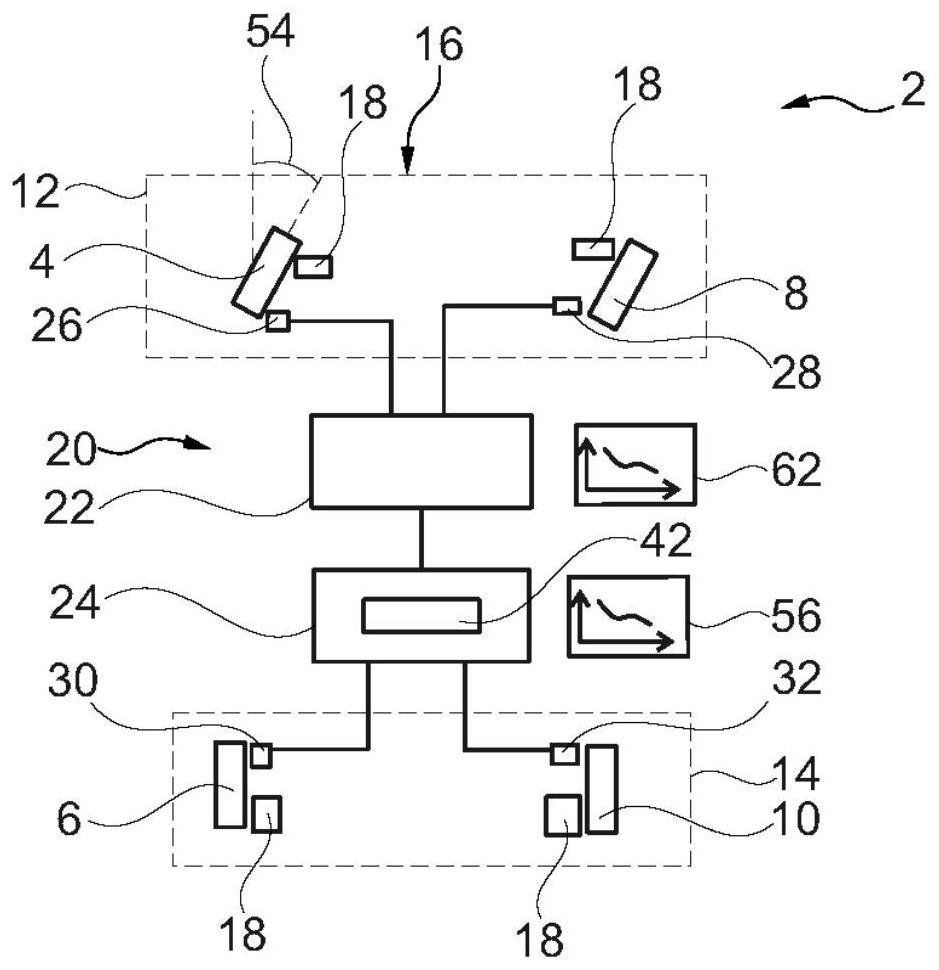

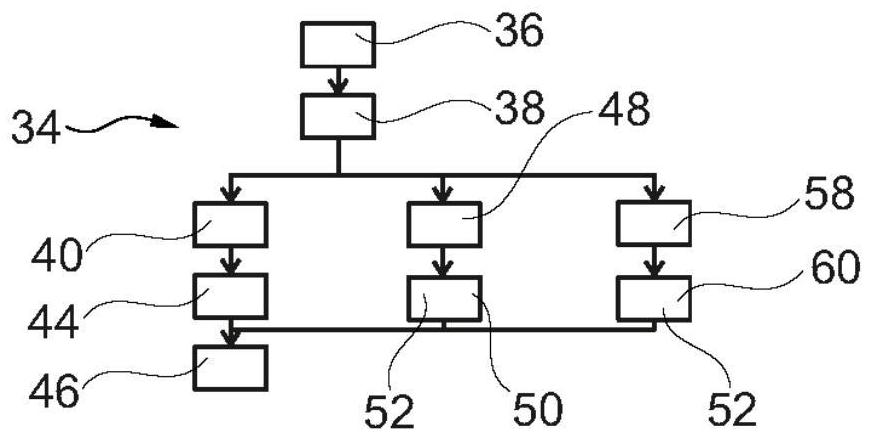

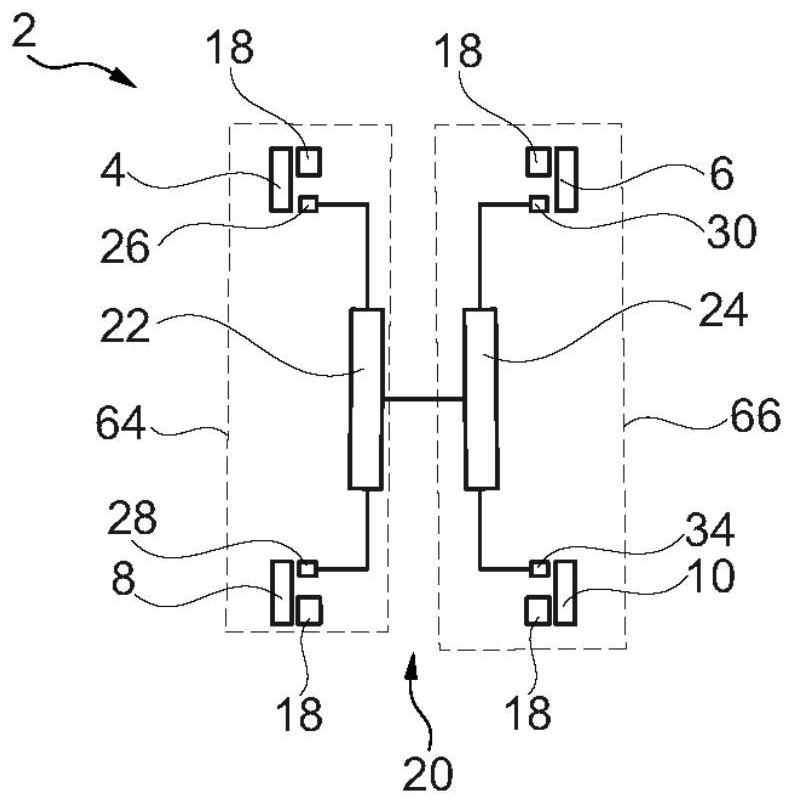

[0048] In the figures, parts corresponding to one another are provided with the same reference numerals.

[0049] exist figure 1 A motor vehicle 2 with a first wheel, a second wheel 6 , a third wheel 8 and a fourth wheel 10 is shown schematically in simplified form. The first wheel 4 and the third wheel 8 are assigned to the front axle 12 , and the second wheel 6 and the fourth wheel 10 are assigned to the rear axle 14 . Motor vehicle 2 has only two axles 12 , 14 and is a passenger vehicle (Pkw).

[0050] Motor vehicle 2 also has a braking system 16 with four brakes 18 , one of brakes 18 being assigned to each of wheels 4 , 6 , 8 , 10 . In a corresponding actuation, the rotational speed of the respective wheel 4 , 6 , 8 , 10 is reduced by means of the brake 18 or, if necessary, blocked. The braking system 16 also has an auxiliary system 20 for determining the wheel slip ratios of the first, second, third and fourth wheels 4 , 6 , 8 , 10 . The auxiliary system 20 has a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com