A Double Cylindrical Cam Clamp with Locking Mechanism

A locking mechanism, cylindrical cam technology, applied in the direction of clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of the clamping plate not being able to perform linear motion, tightening angle, uneven clamping force, and no self-locking function, etc. Achieve the effect of compact structure, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

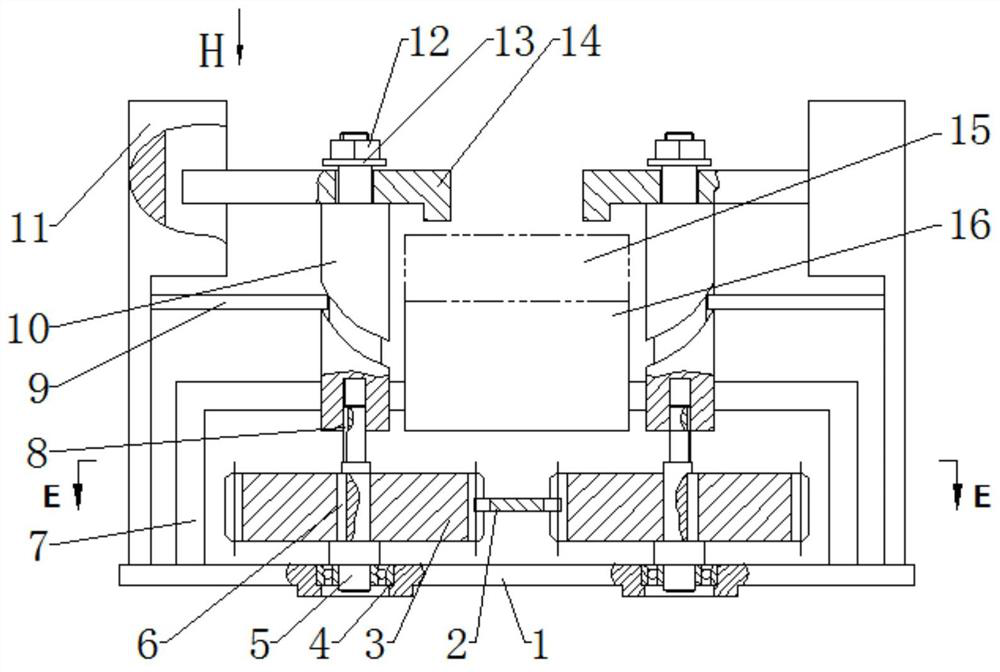

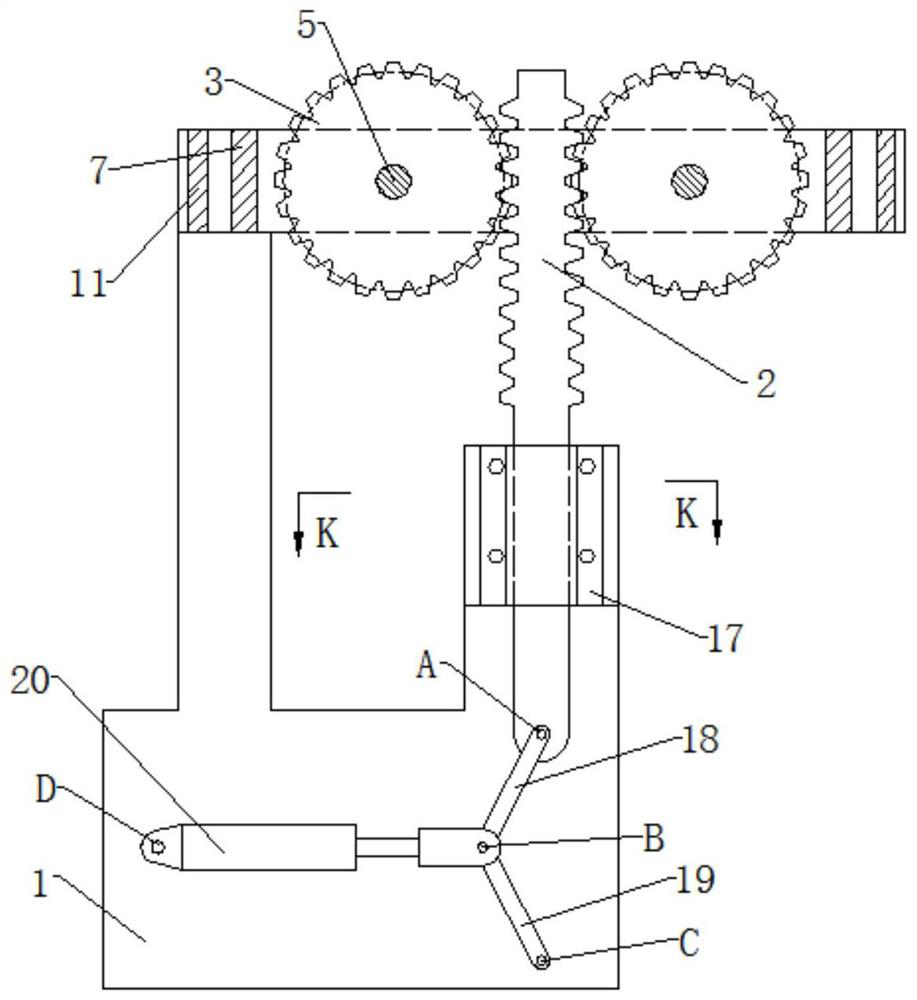

[0023] A double-cylindrical cam clamp with a locking mechanism, comprising a frame 1, on which a rack 2 arranged horizontally and a transmission device for driving the rack 2 to move back and forth, the output of the transmission device The other end of the rack 2 is connected to one end of the rack 2, and the other end of the rack 2 meshes with two symmetrically arranged gears 3 respectively, and the gear 3 is sleeved on the lower end of the gear shaft 5 and fixed with the gear shaft 5 by a positioning key 6, One end of the gear shaft 5 is vertically erected on the frame 1 through the bearing 4, and the other end of the gear shaft 5 is clearance-fitted with the cylindrical cam 10 through the guide key 8 so that the cylindrical cam 10 can rotate synchronously with the gear shaft 5 and the cylindrical cam 10 and the gear shaft 5 have relative movement, and the end of the cylindrical cam 10 away from the gear shaft 5 is sequentially fitted with a pressure plate 14 and a limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com