Carbon nano-tube oriented film, preparation method and applications thereof

A carbon nanotube, oriented film technology, applied in the direction of carbon nanotubes, single-walled carbon nanotubes, oriented carbon nanotubes, etc., can solve problems such as winding, and achieve the effect of solid material guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

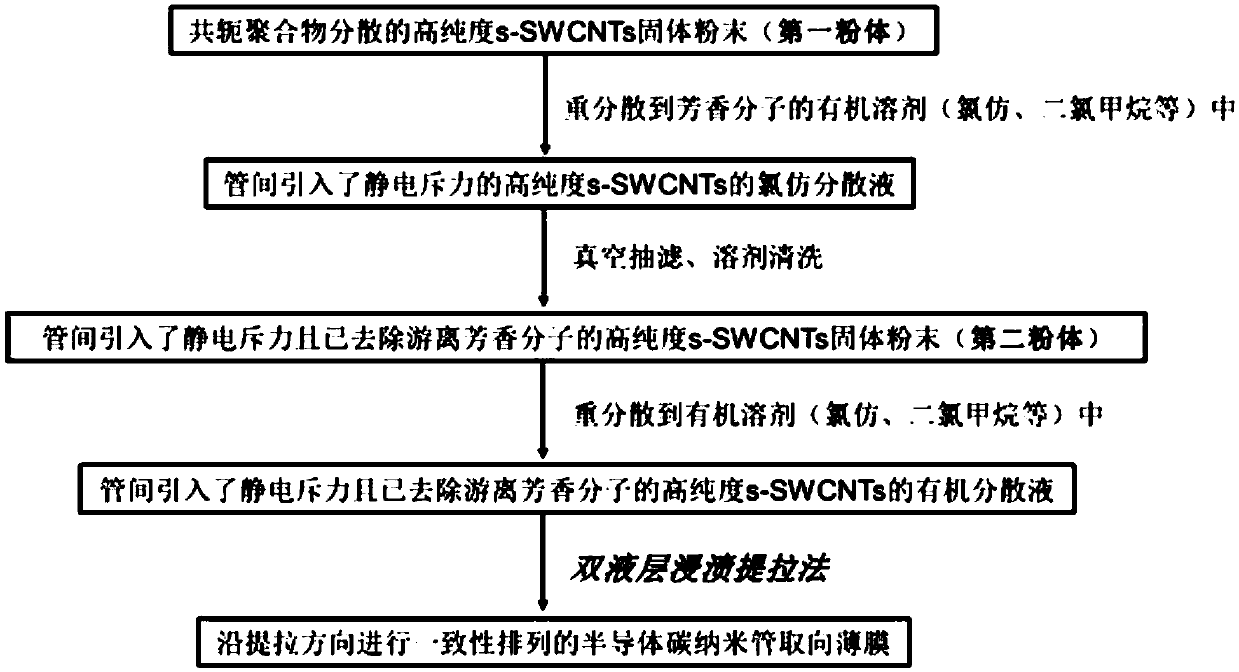

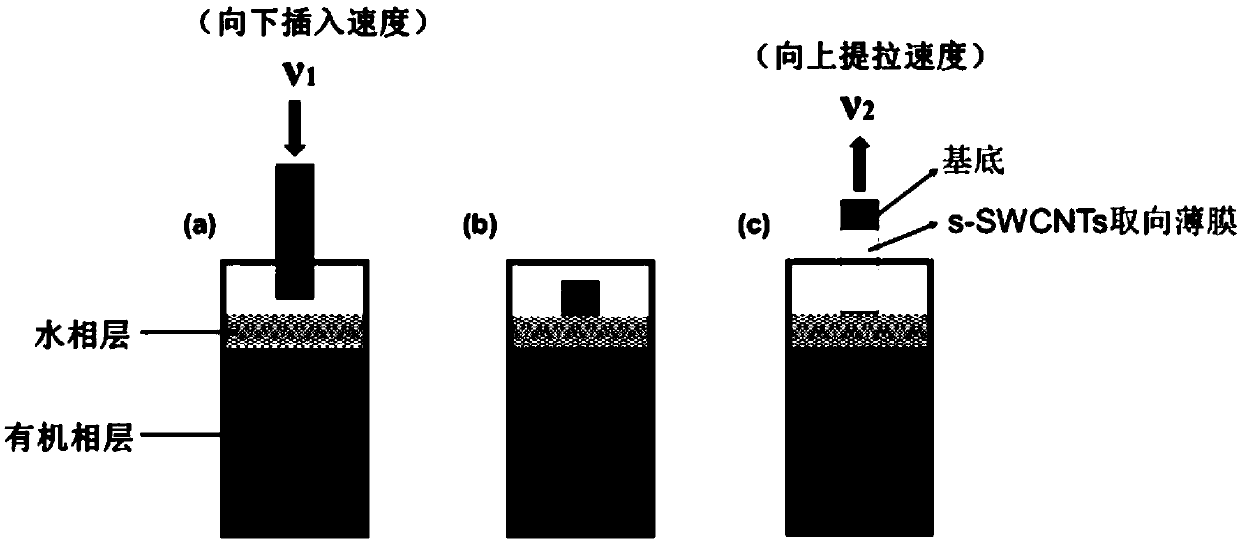

[0067] Another aspect of the embodiments of the present invention also provides the aforementioned method for preparing the carbon nanotube dispersion, which includes:

[0068] At least mix the carbon nanotube powder raw material, the polymer as the carbon nanotube dispersant, and the solvent to form the first dispersion, and make the polymer specifically combine with the selected carbon nanotubes, and then from the second Separation of carbon nanotubes with polymers bound to their surfaces from a dispersion;

[0069] Mixing at least the carbon nanotubes with polymers bound on the surface, aromatic molecules and solvent to form a second dispersion, and combining the aromatic molecules with the selected carbon nanotubes and making the selected carbon nanotubes the surface of the tubes is charged with the same type, and then the carbon nanotubes with the polymer and aromatic molecules bound to the surface are separated from the second dispersion; and

[0070] The carbon nanotub...

Embodiment 1

[0139] 1) On the basis of general procedure 1.1, refer to CN108017049A, adjust the feeding ratio of carbazole linear copolymer (PCz) and single-wall carbon nanotube raw material (obtained from the market, made by arc discharge method) to 1:1 (The following are mass ratios unless otherwise specified.) Toluene was used as a dispersant. After ultrasonic dispersion and centrifugation, the toluene dispersion of high-purity s-SWCNTs dispersed in the polymer was obtained.

[0140] 2) Refer to the general step 1.2 to obtain the first powder.

[0141] 3) Redisperse the first powder obtained in step 2) into a chloroform solution of proflavin sulfate (PFS) with a mass concentration of 0.02 mg / mL to obtain a chloroform dispersion of high-purity s-SWCNTs with electrostatic repulsion introduced between the tubes liquid.

[0142] 4) Refer to the general step 1.4 to obtain the high-purity s-SWCNTs solid powder (ie, the second powder) with electrostatic repulsion introduced between the tubes...

Embodiment 2

[0149] 1) On the basis of general procedure 1.1, referring to CN105819425A, the feed ratio of polycarbazole derivatives and single-walled carbon nanotube raw materials (obtained commercially, made by plasma discharge method) is adjusted to 2:1, and xylene is used as Dispersant. After ultrasonic dispersion and centrifugation, the xylene dispersion of high-purity s-SWCNTs dispersed in the polymer was obtained.

[0150] 2) Refer to the general step 1.2 to obtain the first powder.

[0151] 3) Redisperse the first powder obtained in step 2) into a dichloromethane solution of neutral red (NR) with a mass concentration of 0.01 mg / mL to obtain high-purity s-SWCNTs with electrostatic repulsion between the tubes. Methyl chloride dispersion

[0152] 4) Refer to the general step 1.4 to obtain a high-purity s-SWCNTs solid powder (ie, the second powder) with electrostatic repulsion introduced between the tubes and free neutral red (NR) molecules removed.

[0153] 5) Redisperse the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com