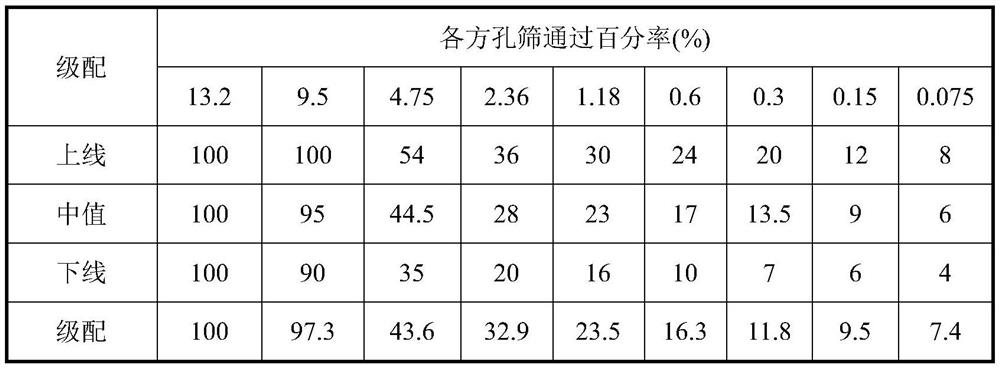

A special modified asphalt for u-pave and its preparation method and application method

A technology of modified bitumen and matrix bitumen, used in climate change adaptation, building components, building thermal insulation materials, etc. The effect of good compactability, improved utilization, and increased resistance to water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Embodiment 1: a kind of U-pave special modified asphalt and its preparation method and application method

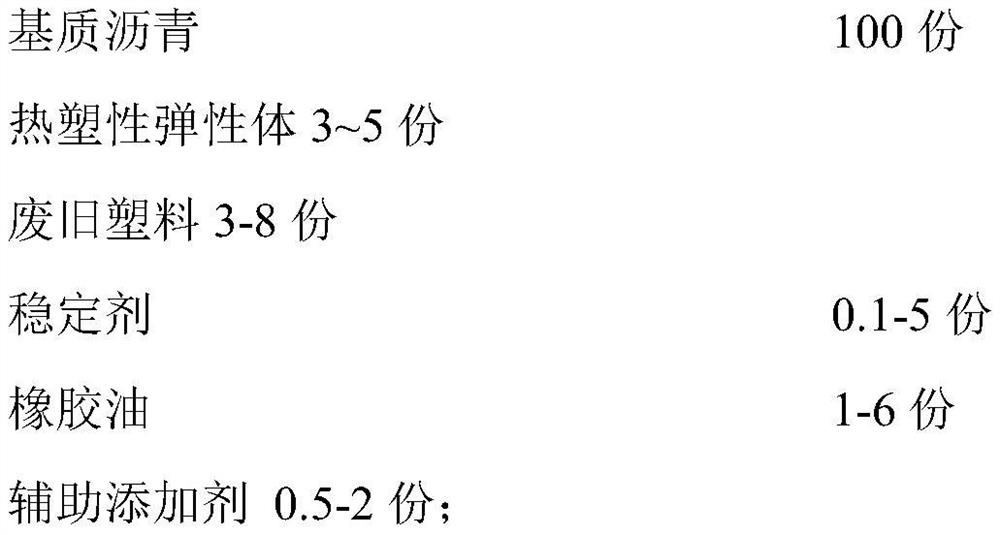

[0045] A U-pave special modified asphalt, calculated in parts by weight, includes the following components:

[0046] 100 parts of base asphalt, 5 parts of linear SBS (YH791), 0.4 parts of stabilizer, 3 parts of rubber oil, 0.5 parts of waste plastics, 0.5 parts of auxiliary additives; wherein, auxiliary additives are prepared from the following components: 50ml ethanol, 1mol bisphenol A , 3mol formaldehyde, 3mol diethylenetriamine, 0.5gY(OTf) 3 .

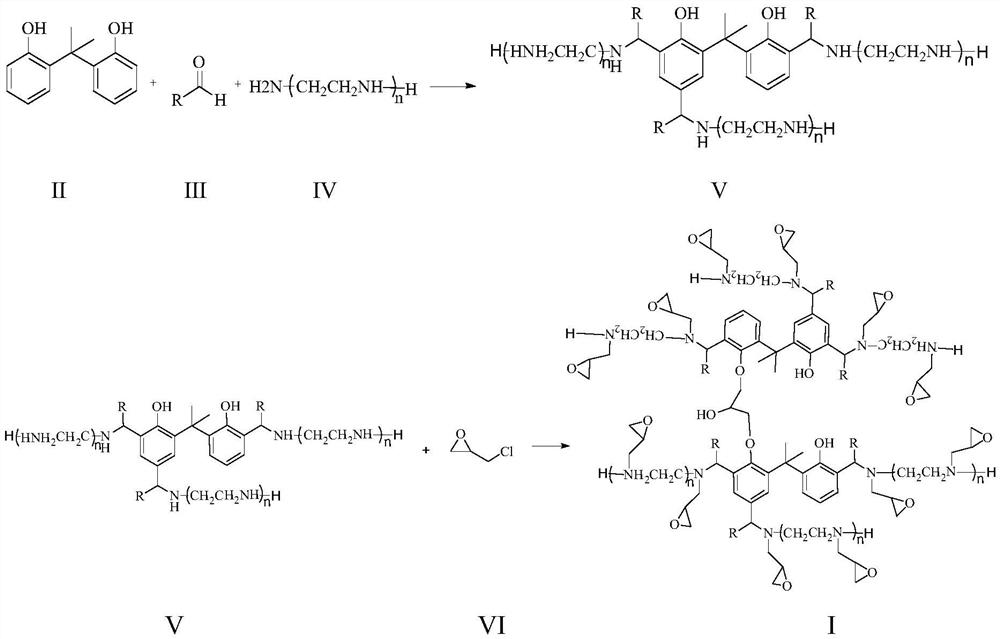

[0047] Preparation of auxiliary additives:

[0048] S1. Add 50ml of ethanol, 1mol of bisphenol A, 3mol of formaldehyde, 3mol of diethylenetriamine and 0.5g of catalyst Y(OTf) into the three-necked flask 3 , heating up to 80°C to react to obtain an intermediate compound;

[0049] S2. Then, the temperature was lowered to 60°C in the three-necked bottle, and 9 mol of epichlorohydrin was slowly added dropwise into the th...

Embodiment 2

[0067] Example 2: A special modified asphalt for U-pave and its preparation method and application method

[0068] A U-pave special modified asphalt, calculated in parts by weight, includes the following components:

[0069] 100 parts of base asphalt, 3 parts of star-shaped SBS, 0.7 parts of stabilizer, 3 parts of waste plastics, 2 parts of auxiliary additives; Among them, auxiliary additives are prepared from the following components: 50ml ethanol, 1mol bisphenol A, 3mol formaldehyde, 3mol triethylene Tetramine, 0.5gLn(OTf) 3 .

[0070] Preparation of auxiliary additives:

[0071] S1. Add 50ml of ethanol, 1mol of bisphenol A, 3mol of benzaldehyde, 3mol of triethylenetetramine and 2g of catalyst Ln(OTf) into the three-necked flask 3 , heating up to 80°C to react to obtain an intermediate compound;

[0072] S2. Cool down the three-necked bottle to 60° C., slowly add 9 mol of epichlorohydrin dropwise into the three-necked bottle at a rate of 45 drops / min; react at constant t...

Embodiment 3

[0088] Example 3: A special modified asphalt for U-pave and its preparation method and application method

[0089] A U-pave special modified asphalt, calculated in parts by weight, includes the following components:

[0090] 100 parts of base asphalt, 10 parts of SBR, 0.2 parts of stabilizer, 6 parts of rubber oil, 8 parts of waste plastics, 1.8 parts of auxiliary additives; wherein, auxiliary additives are prepared from the following components: 50ml ethanol, 1mol bisphenol A, 3mol formaldehyde, 3mol tetraethylenepentamine, 0.5gYb(OTf) 3 .

[0091] Preparation of auxiliary additives:

[0092] S1. Add 50ml of ethanol, 1mol of bisphenol A, 3mol of tert-butyl formaldehyde, 3mol of tetraethylenepentamine and 5g of catalyst Yb(OTf) into the three-necked flask 3 , heating up to 80°C to react to obtain an intermediate compound;

[0093] S2. Cool down the three-necked bottle to 60° C., slowly add 9 mol of epichlorohydrin into the three-necked bottle at a rate of 20 drops / min; rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com