Steel-concrete hybrid beam combination section adopting corrugated steel plates for force transmission

A technology of corrugated steel plates and joint sections, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of heavy construction workload, reduce the strength of concrete in the hole, and low construction efficiency, so as to improve construction efficiency, weaken the constraint effect, Reduces the effect of shear action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

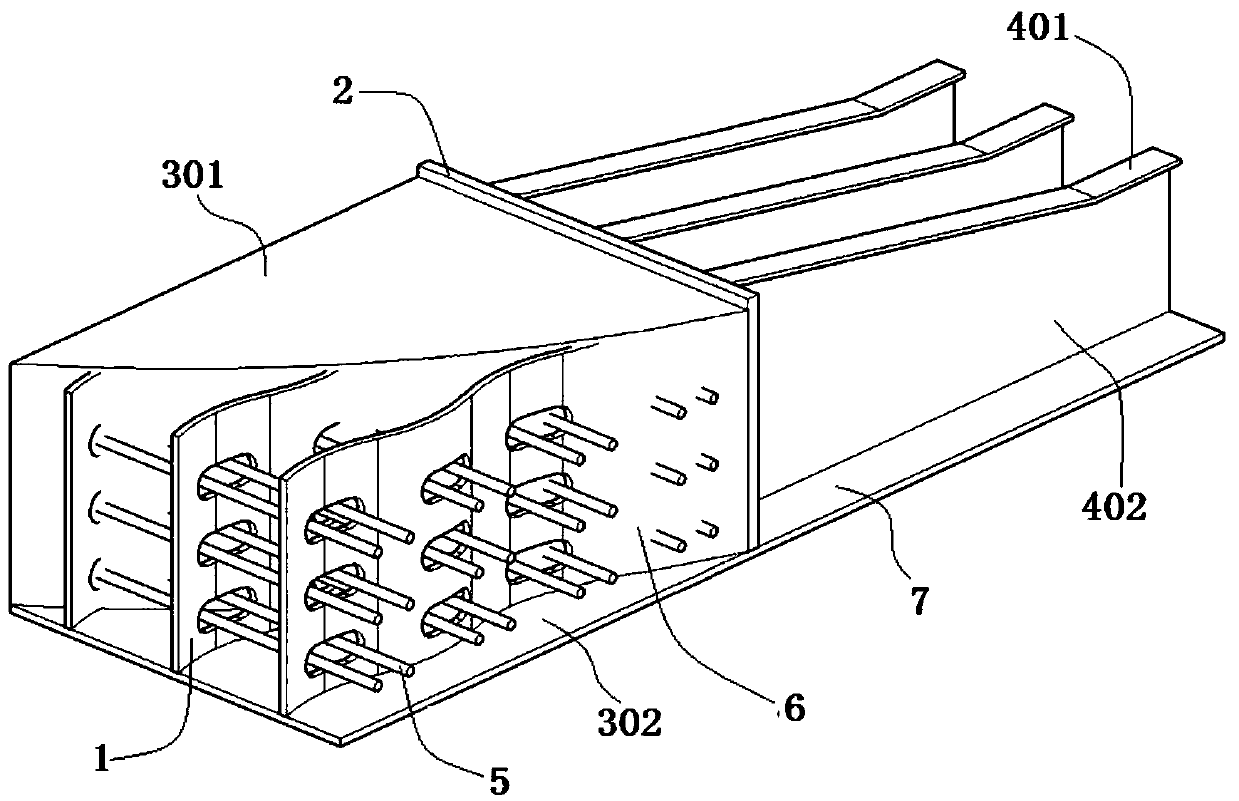

[0027] This embodiment discloses a steel-concrete hybrid beam joint section using corrugated steel plates for force transmission, including several corrugated steel partitions 1 , pressure bearing plates 2 and steel boxes 3 for the joint section.

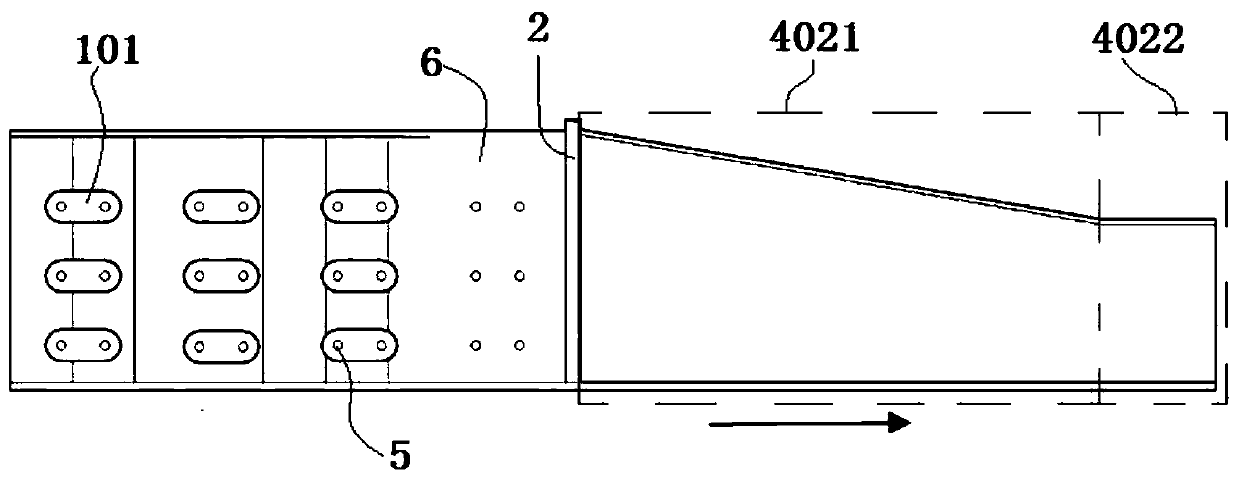

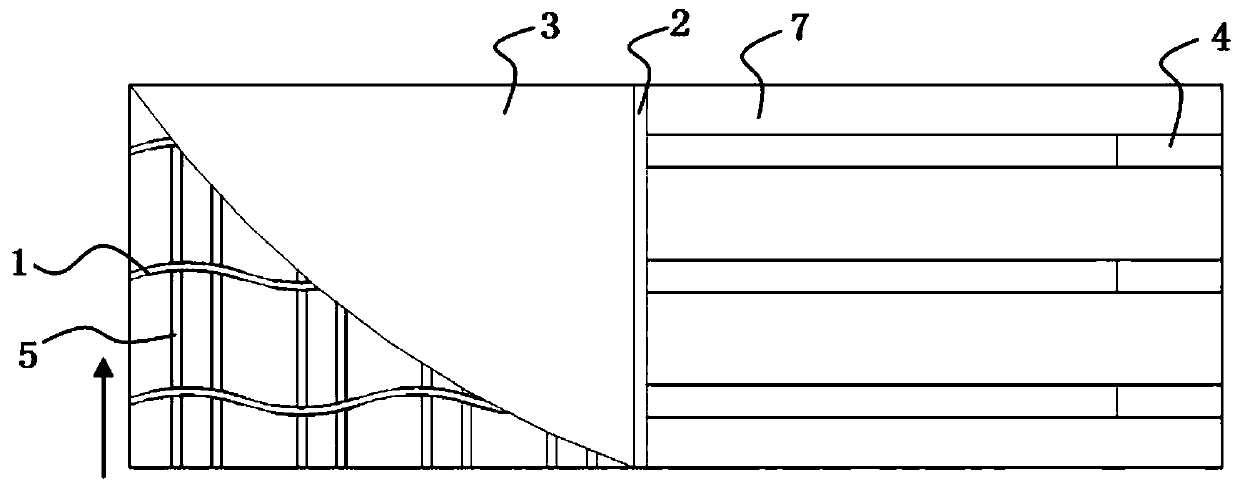

[0028] see figure 2 , the direction of the arrow in the figure is the longitudinal bridge direction, and the plate surface of the pressure bearing plate 2 is perpendicular to the longitudinal bridge direction. see image 3 , one plate surface of the pressure bearing plate 2 is connected with several T-shaped stiffeners 4, and the other plate surface is connected with the side wall of the steel box 3 of the joint section, and the steel box 3 of the joint section is a square box arranged horizontally.

[0029] see figure 1 , the T-shaped stiffener 4 includes a flange 401 and a web 402, the plate surface of the web 402 is perpendicular to the horizontal plane, and the length direction of the web 402 is consistent with the longitudin...

Embodiment 2

[0042] This embodiment discloses a steel-concrete hybrid beam joint section using corrugated steel plates for force transmission, including several corrugated steel partitions 1 , pressure bearing plates 2 and steel boxes 3 for the joint section.

[0043] see figure 2 , the direction of the arrow in the figure is the longitudinal bridge direction, and the plate surface of the pressure bearing plate 2 is perpendicular to the longitudinal bridge direction. see image 3 , one plate surface of the pressure bearing plate 2 is connected with several T-shaped stiffeners 4, and the other plate surface is connected with the side wall of the steel box 3 of the joint section, and the steel box 3 of the joint section is a square box arranged horizontally.

[0044] see figure 1 Or 2, a number of corrugated steel partitions 1 are connected between the top plate 301 and the bottom plate 302 of the steel box 3 of the joint section, and the plurality of corrugated steel partitions 1 are arr...

Embodiment 3

[0052] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to Figure 4 In (2) figure, the waveform shape of the corrugated steel separator 1 is an arc curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com