Waterproof structure of structure bottom plate and construction method

A waterproof structure and construction method technology, which is applied in the direction of basic structure engineering, water conservancy engineering, underwater structures, etc., can solve the problems of waterproof membrane damage, violation, and increased safety risks of foundation pits, and achieve the effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

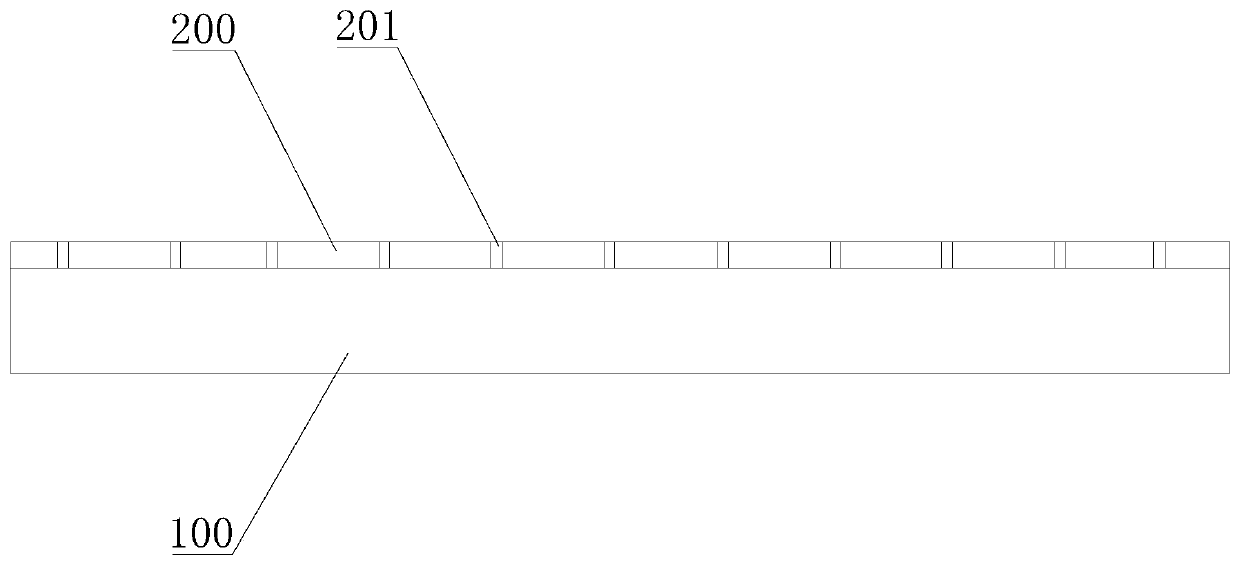

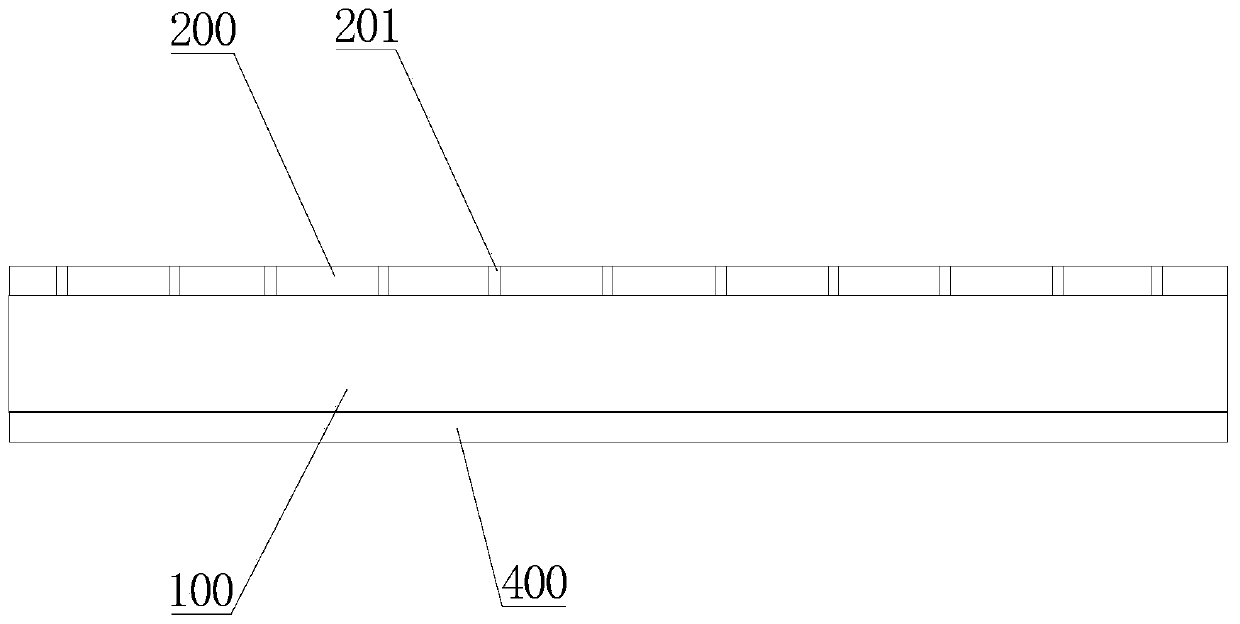

[0044] Please refer to figure 1 and figure 2 , the present embodiment provides a waterproof structure of a structural bottom plate, which includes a waterproof layer 100 and a permeable layer 200;

[0045]One of the faces of the permeable layer 200 is in contact with the waterproof layer 100; the other face of the permeable layer 200 is used for laying the structural floor;

[0046] The permeable layer 200 is provided with a slit 201, and the slit 201 can pass the slurry of the structural bottom plate.

[0047] In this embodiment, the waterproof layer 100 is the main body of the waterproof structure. One of the surfaces of the waterproof layer 100 is laid on the excavation surface, and the other surface of the waterproof layer 100 covers the above-mentioned permeable layer 200. Since the permeable layer 200 There is a gap 201 enough for the slurry to pass through the structural bottom plate, so after pouring the slurry for the structural bottom plate, the slurry will pass t...

no. 2 example

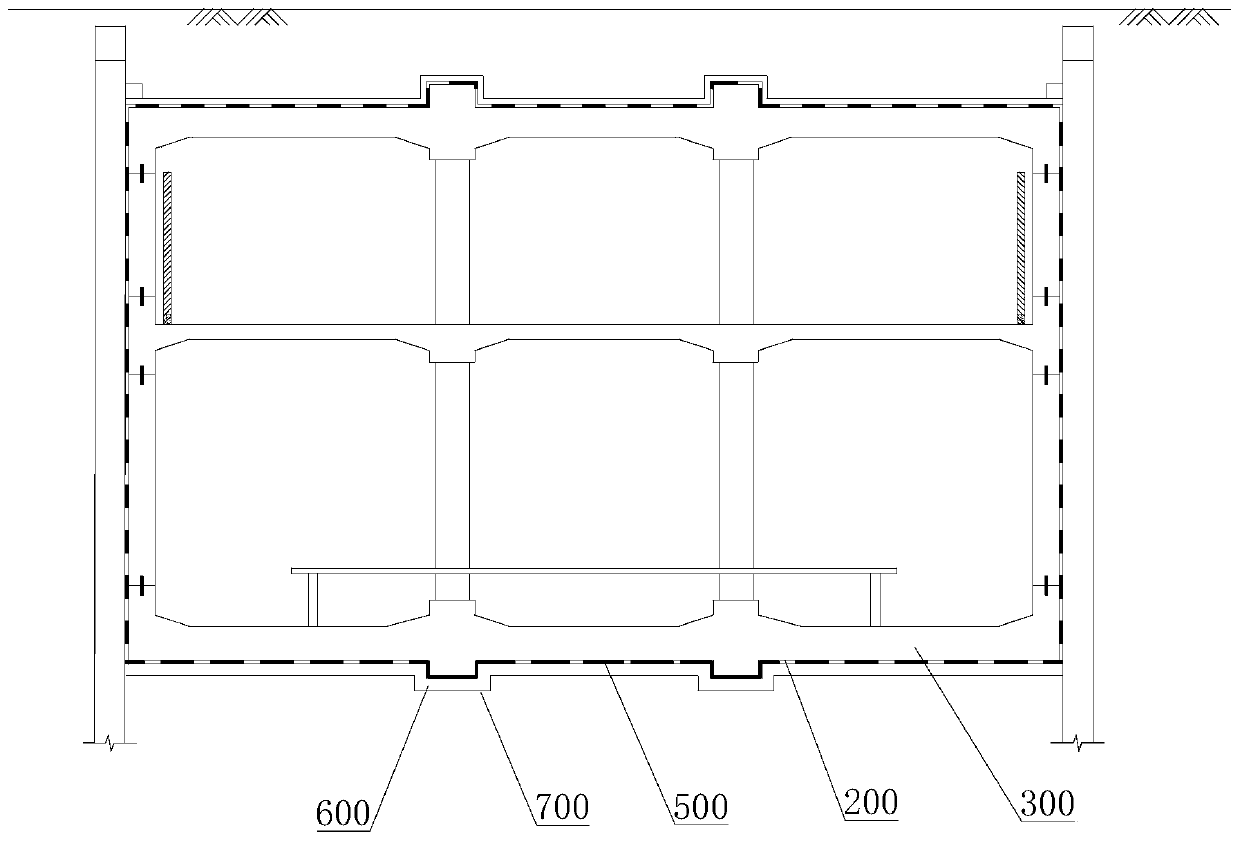

[0062] Please refer to image 3 , the present embodiment provides a construction method for a waterproof structure of a structural bottom plate, which includes:

[0063] Covering the permeable layer 200 on one surface of the waterproof layer;

[0064] Laying the other side of the waterproof layer on the excavation surface 700;

[0065] The laying of the waterproof layer is checked.

[0066] Specifically, the waterproof layer adopts a polymer self-adhesive film waterproof roll material 500, and a layer of non-stick permeable layer 200 is arranged on the outside of the polymer self-adhesive film waterproof roll material. The non-stick permeable layer 200 has both non-stick Adhesive properties, and there are enough gaps 201, non-stick properties provide convenience for construction, the gaps 201 facilitate the penetration of subsequent concrete slurry (slurry of the structural floor 300), and have physical or chemical crosslinking reactions with the self-adhesive adhesive layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com