High molecular polymer emulsion and preparation method thereof, functional coating, film layer and waterproof membrane

A technology of high molecular polymer and polymer emulsion, applied in the direction of coating, roof covering, building structure, etc., can solve the problems of white pollution of isolation film, fire-baked waterproof membrane, etc., to avoid fire risk and construction efficiency Improved and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

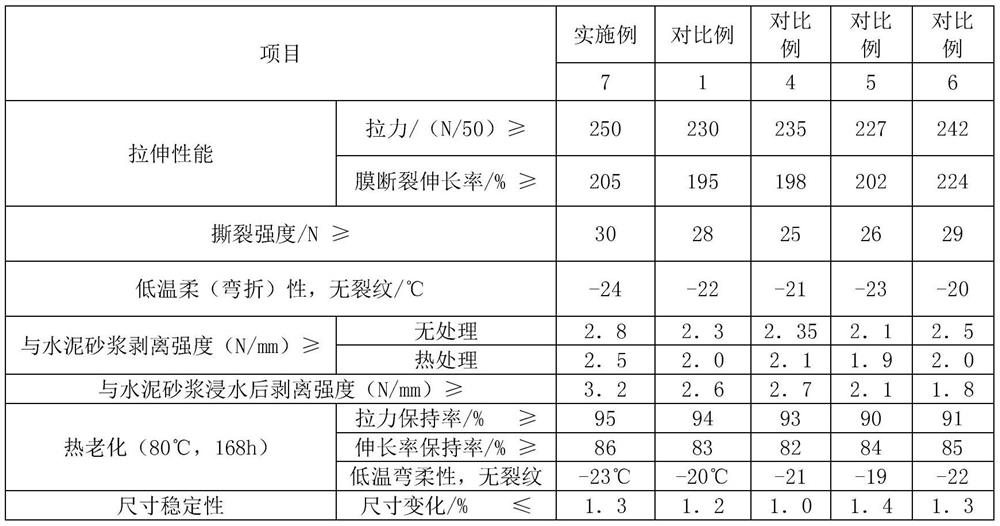

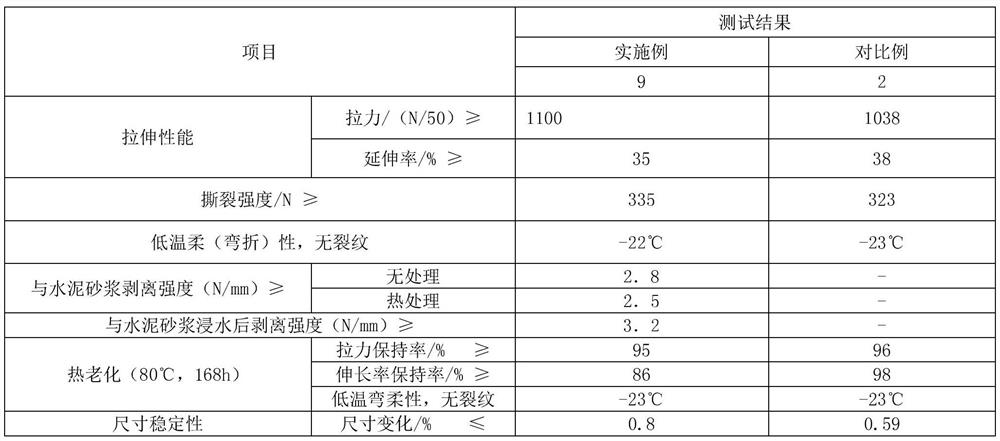

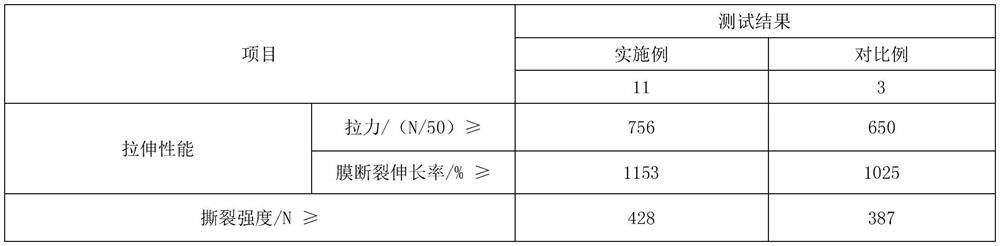

Examples

Embodiment 1

[0046] This example provides a high molecular polymer emulsion. In terms of mass percentage, in the raw materials of the polymer emulsion, methacrylic acid accounts for 15%, methyl methacrylate accounts for 12%, and butyl methacrylate accounts for 12%. 5%, sodium persulfate 0.4%, sodium dodecyl sulfonate 0.2%, soybean lecithin 0.8% (purchased from Shaanxi Xintianyu Biotechnology Co., Ltd.), ethylene glycol titanium 0.1%, deionized water 0.1% 66.5%.

[0047] The preparation method includes: (1) putting deionized water, sodium persulfate, sodium dodecyl sulfonate and soybean lecithin in proportions by weight into a reaction kettle, and stirring them evenly; stirring at a speed of 100 rpm for 20 minutes; (2) get the methacrylic acid of total amount 1 / 3 and the methyl methacrylate of 1 / 3, the butyl methacrylate of 1 / 3, join in the reactor after mixing, add ethylene glycol while stirring (3) Slowly add the remaining methacrylic acid, the remaining methyl methacrylate, and the rema...

Embodiment 2

[0055] This example provides a high molecular polymer emulsion. In terms of mass percentage, the raw materials of the polymer emulsion are 12% of methacrylic acid, 12% of methyl methacrylate, and 12% of butyl methacrylate. 5%, ammonium persulfate 0.25%, sodium dodecyl sulfonate 0.15%, soybean lecithin 0.5%, ethylene glycol titanium 0.2%, deionized water 69.9%.

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] This example provides a high molecular polymer emulsion. In terms of mass percentage, the raw materials of the polymer emulsion are 15% of methacrylic acid, 15% of methyl methacrylate, and 0.2% of sodium persulfate. , sodium dodecyl sulfonate accounted for 0.25%, soybean lecithin accounted for 0.8%, ethylene glycol titanium accounted for 0.15%, deionized water accounted for 68.6%.

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com