Dust removal device for mining equipment

A mining equipment and dust removal device technology, applied in mining equipment, combined devices, safety devices, etc., can solve the problems of polluting the surrounding environment, poor air dust removal effect, complex structure, etc., and achieve water saving, good dust removal effect, no dust removal The effect of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

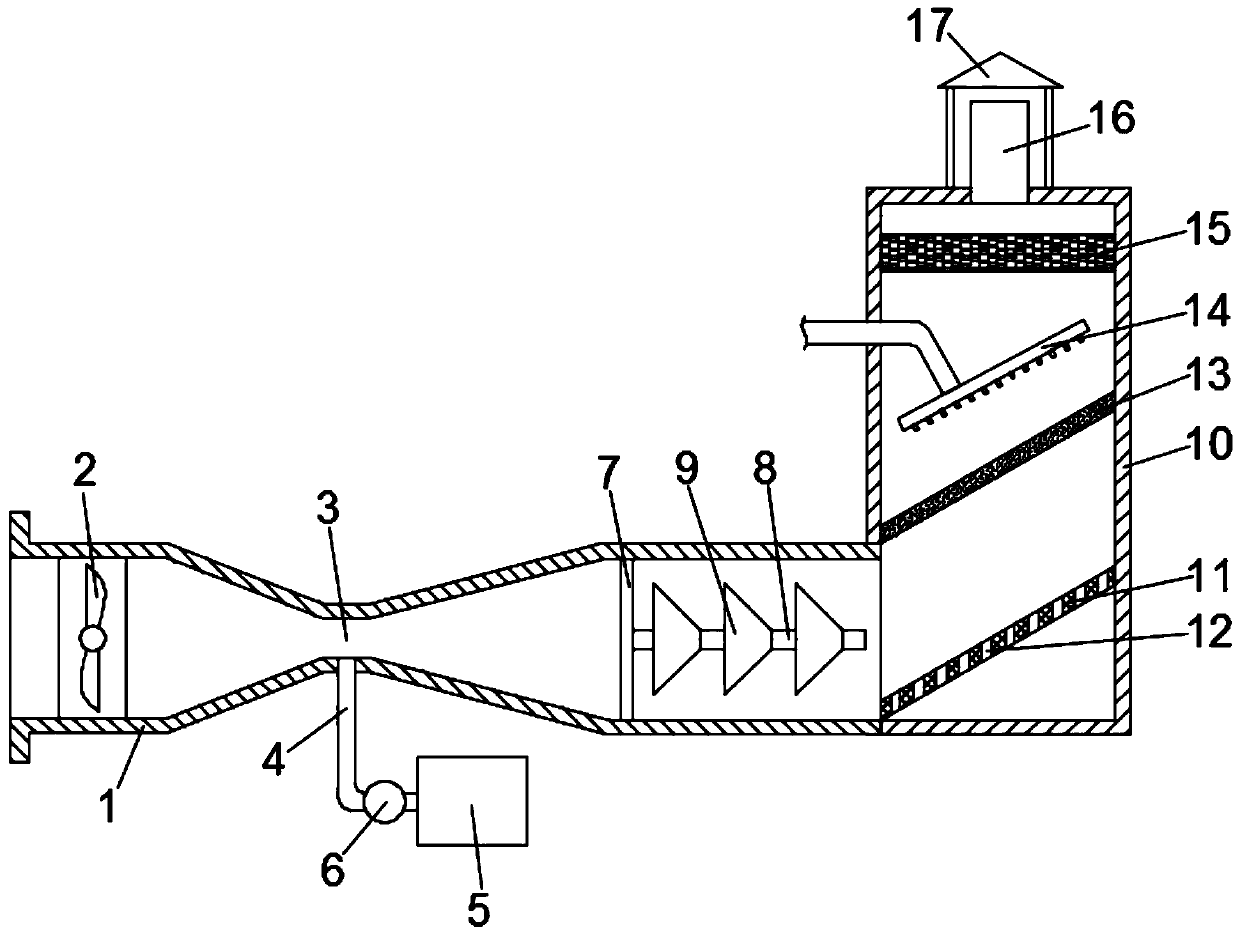

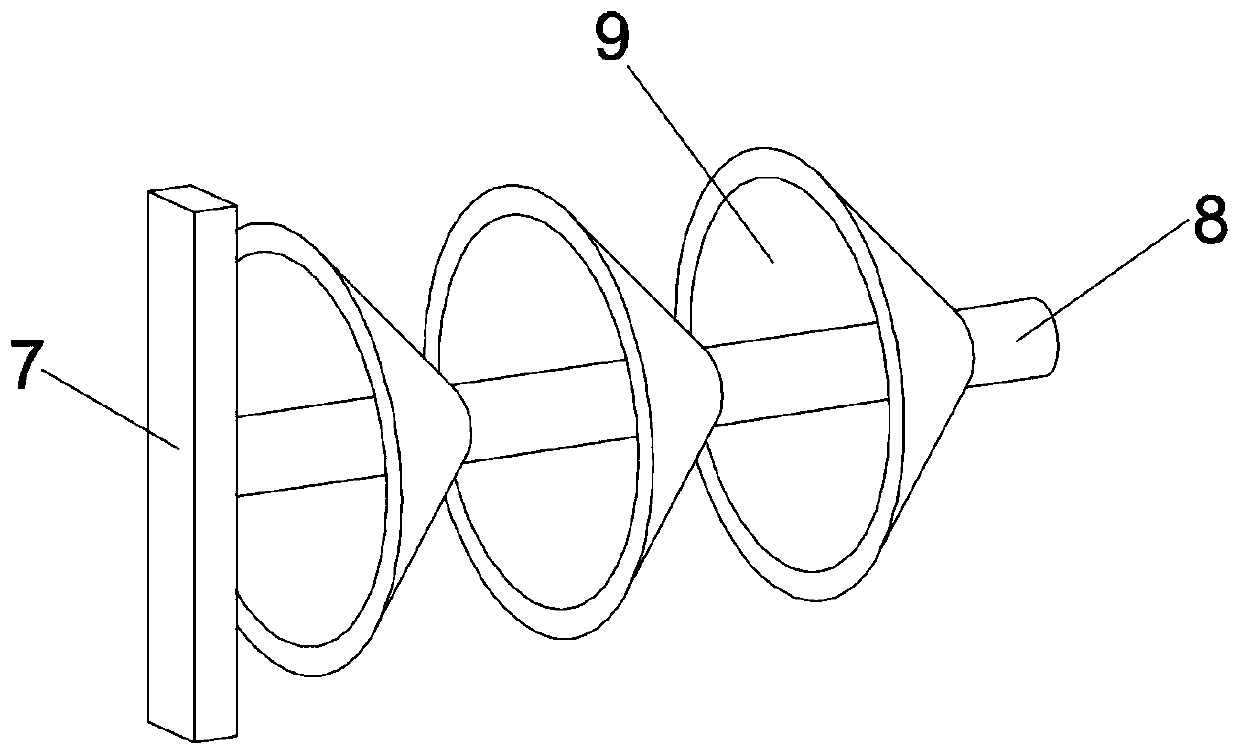

[0023] See Figure 1-2 , A dust removal device used in mining equipment includes a first pipe 1 and a second pipe 10. An air suction fan 2 is installed on the left side of the first pipe 1, and the middle of the first pipe 1 shrinks to form a throat 3, A water inlet pipe 4 is connected below the throat 3, and the lower end of the water inlet pipe 4 is connected to a water tank 5; a fixing plate 7 is vertically installed on the right side of the first pipe 1, and a connecting shaft 8 is provided on the fixing plate 7 , The connecting shaft 8 is evenly distributed with a number of tapered baffles 9; the right end of the first pipe 1 is in communication with the second pipe 10, and the second pipe 10 is sequentially installed with an inclined plate 11 and a filter from bottom to top. The plate 13 and the drying plate 15, the inclined plate 11 is provided with a number of through holes 12, the filter plate 13 and the drying plate 15 are provided with a spray head 14; the upper end ...

Embodiment 2

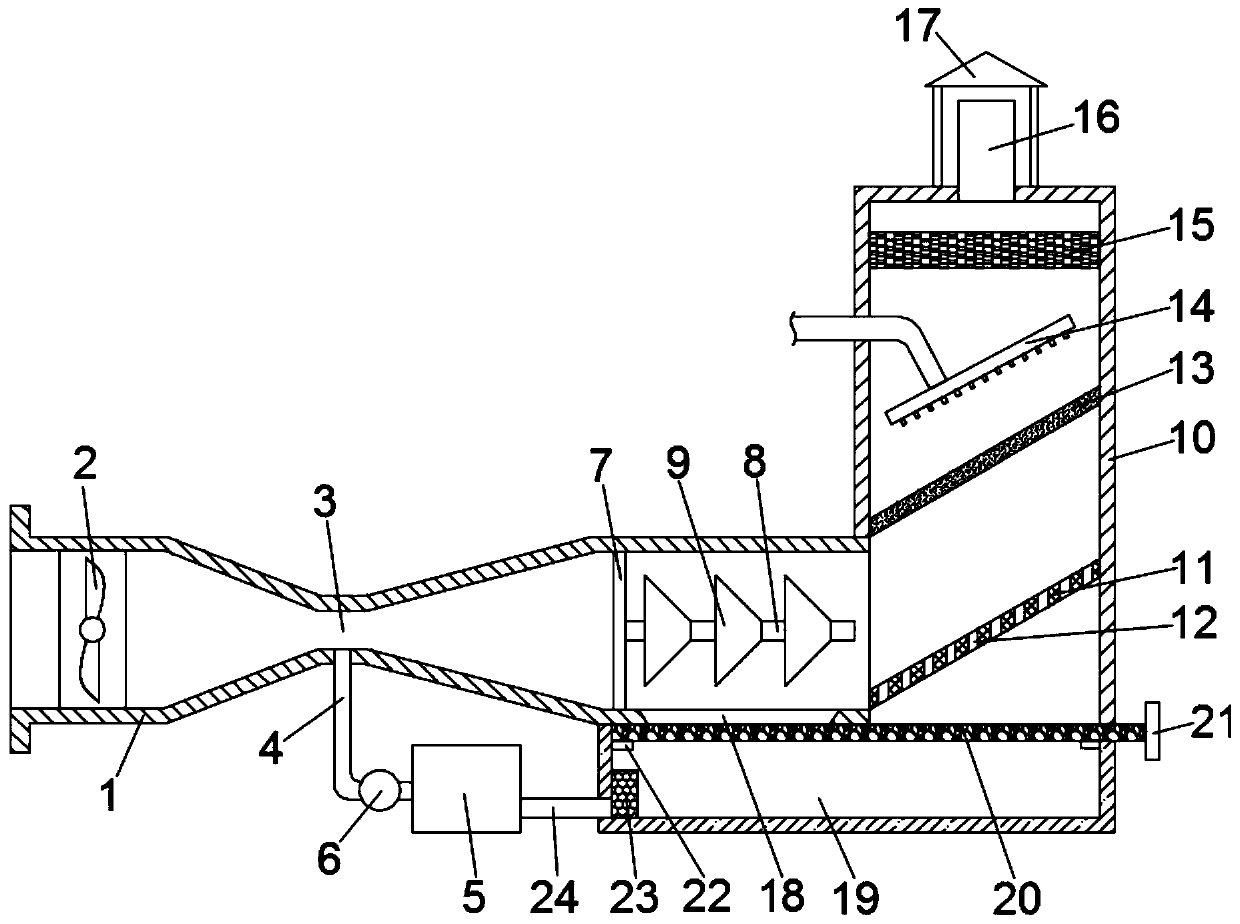

[0032] See image 3 When the dust-laden air carrying a large amount of water vapor collides with the conical baffle 9 and the inclined plate 11, some water droplets with large particles of dust will fall due to their heavy weight. In order to facilitate the collection of this part of the water droplets, this implementation The example is further improved on the basis of Example 1. The improvement is: a collection box 19 is provided below the tapered baffle 9 and the inclined plate 11, and the top of the collection box 19 is connected to the right end of the first pipe 1. Connected to the bottom of the second pipe 10, the right bottom of the first pipe 1 is provided with a through groove 18, and a filter 23 is installed on the inner wall of the collecting tank close to the water tank 5. The filter 23 and the water tank 5 There is a return pipe 24 connected between;

[0033] Specifically, water droplets containing large particles of dust fall from the first pipe 1 and the second pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com