Integral floating sealing structure

A floating seal and integral technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as inconvenient installation and use, and achieve the effects of increasing reliability, strong practicability, and improving installation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

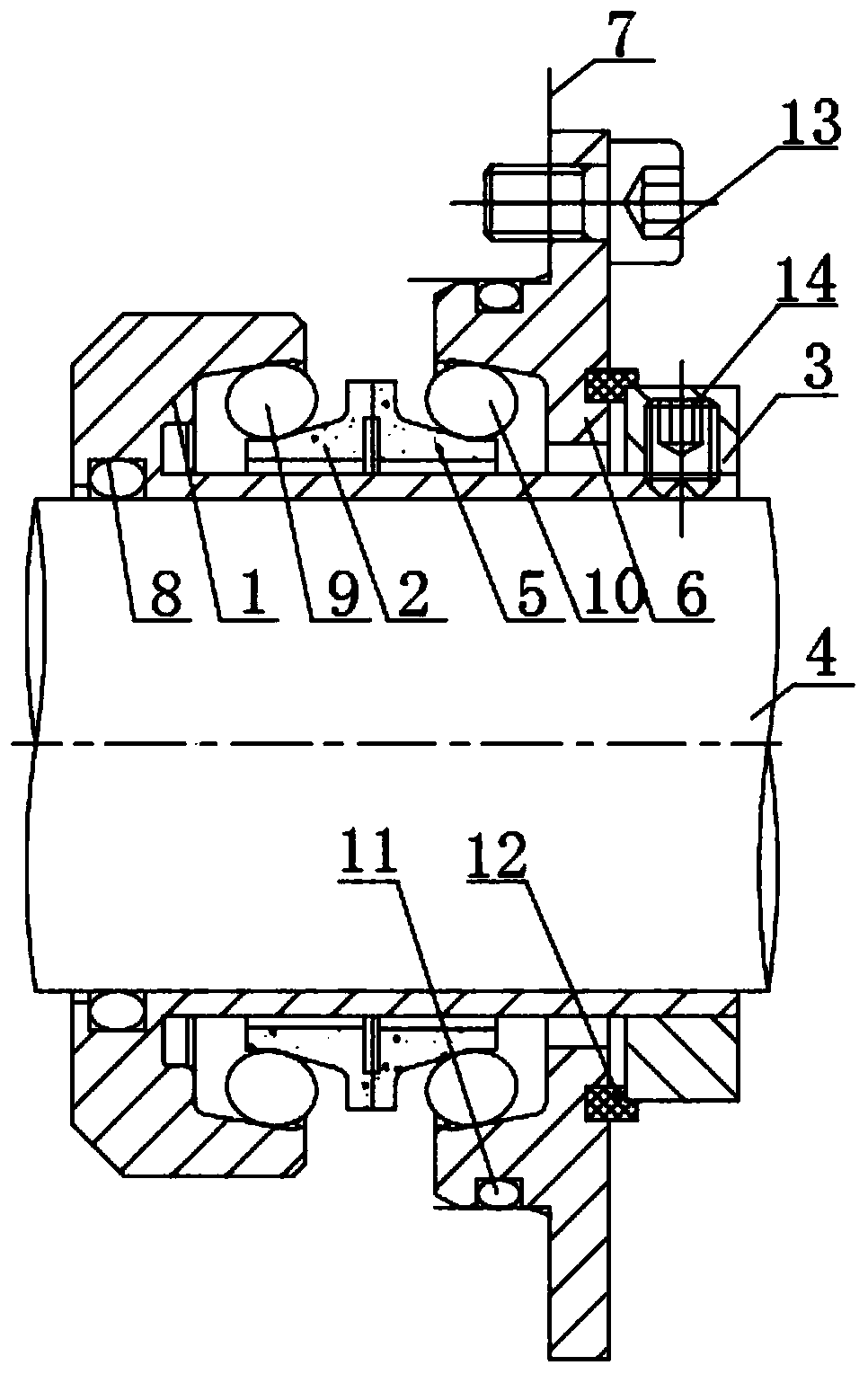

[0022] Such as figure 1 As shown, this embodiment provides an integral floating seal structure, including rotating parts and stationary parts; 3 and the moving ring 2 are both sleeved on the outer circumference of the shaft sleeve 1; the stationary part includes an end cover 6 and a static ring 5 for sealing connection with the moving ring 2, and the static ring 5 and the end cover 6 are both sleeved on the shaft sleeve 1 Perimeter; the outer edge of the end cover 6 is connected with the equipment cavity 7 .

[0023] In this example, if figure 1 As shown, the moving ring 2 is located in the middle of the shaft sleeve 1 , and the drive ring 3 is sleeved at the end of the shaft sleeve 1 .

[0024] In this example, if figure 1 As shown, the static ring 5 is located between the moving ring 2 and the driving ring 3 , and the end cover 6 is located between the static ring 5 and the driving ring 3 .

[0025] In this example, if figure 1 As shown, a first sealing ring 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com