A modular pressure relief assembly capable of automatic pressure relief

A pressure relief component, modular technology, applied in the direction of engine components, valve devices, safety valves, etc., can solve the problem that the pressure in the liquid cooling equipment cannot be completely relieved, the liquid cooling system of the liquid cooling equipment fails, and the structure, volume and shape are inconsistent. The same problem, to achieve the effect of reducing the phenomenon of bursting damage, compact structure, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

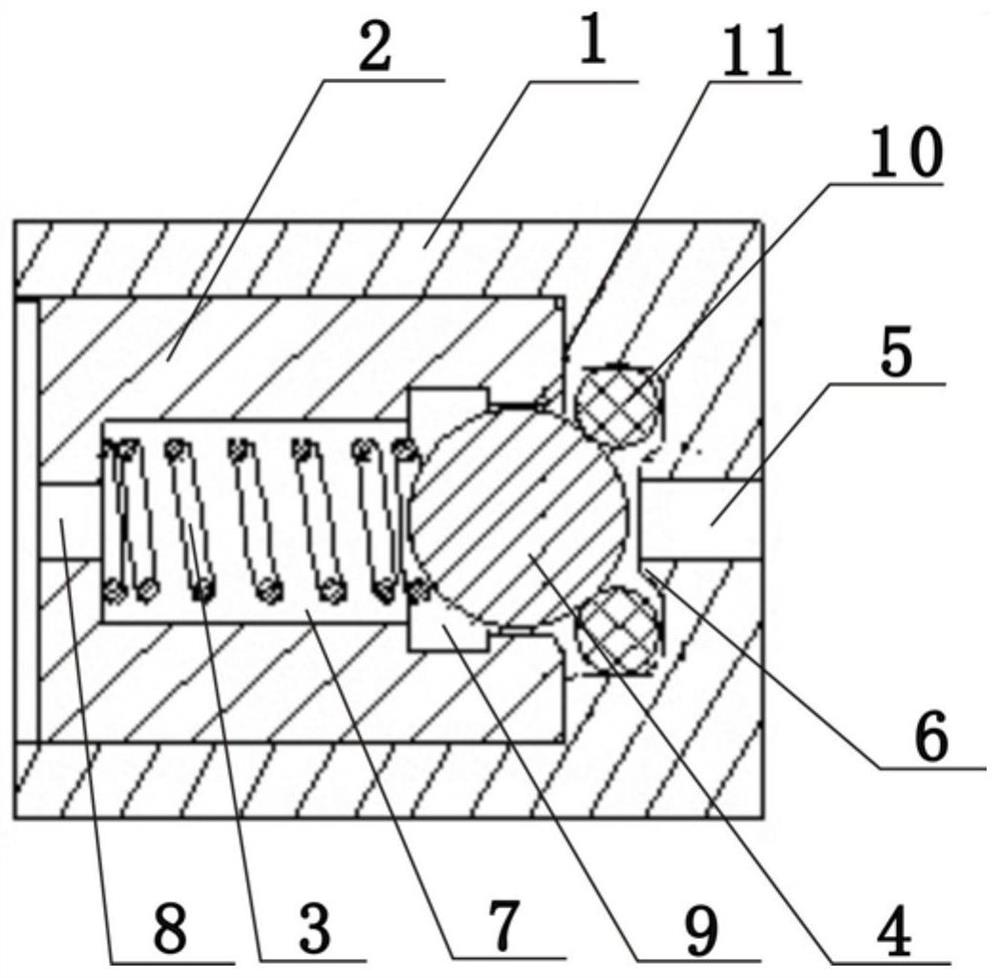

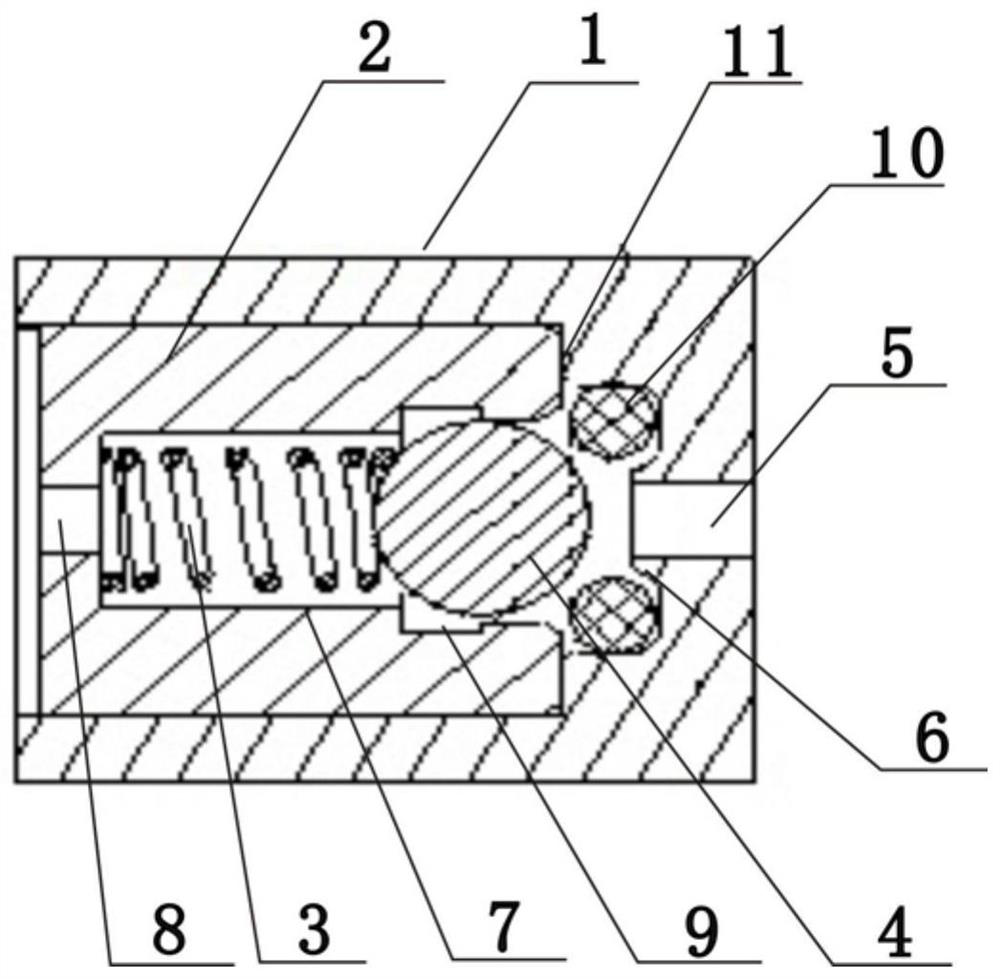

[0017] combined with Figure 1~2 , a modular pressure relief assembly that can automatically relieve pressure, including a housing 1, a positioning block 2, a spring 3 and a ball 4; the housing 1 is hollow inside, and one end is open, and the other end of the housing 1 A through hole 5 corresponding to the internal cavity is provided, and an annular boss 6 coaxial with the through hole 5 is provided at the position corresponding to the through hole 5 in the cavity of the housing 1; the inner sealing device of the open end of the housing 1 There is a positioning block 2; as required, the outer wall of the positioning block 2 is connected to the inner wall of the cavity of the housing 1 by corresponding threads, the structure is simple, easy to assemble, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com