Outer polygonal reinforced corrugated pipe and forming process thereof

A molding process, polygonal technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve problems such as difficult interconnection, reduced pipe flexibility, and inability to solve safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

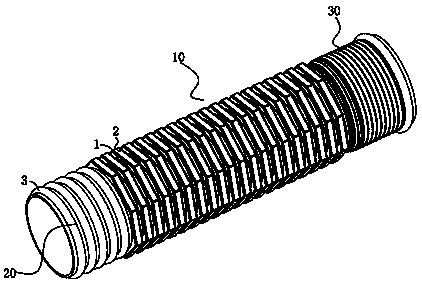

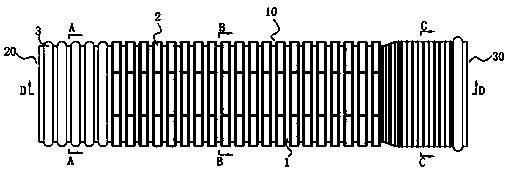

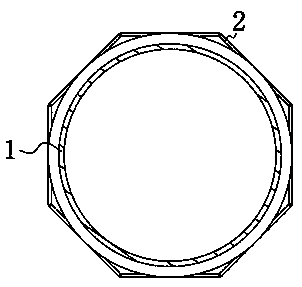

[0026] Such as figure 1 - As shown in 6, a forming process for an outer polygon reinforced bellows, comprising the following steps:

[0027] 1) The extruder extrudes the molten pipe body material from the die head, and the pipe body material extruded from the die head enters the corrugated pipe forming die in the form of a ring pipe. The die head is circular, so that it can form circular pipes.

[0028] 2) The ring pipe is formed by the bellows forming mold. When the ring pipe is formed in the bellows forming mold, the outer wall of the ring pipe is formed with multiple polygonal ring protrusions 2 through more than three continuous polygonal mold modules. The circular mold module at at least one end of the continuous polygonal mold module makes the outer wall of at least one end of the annular pipe with polygonal annular protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com