Patch type inclined ball switch and integrated pressing production process thereof

A ball switch and chip technology, applied in the field of chip tilt ball switch and its integrated pressing production process, can solve the problems of low production efficiency, single structure, small function, etc., and achieve improved production efficiency, diversified and advanced structure. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

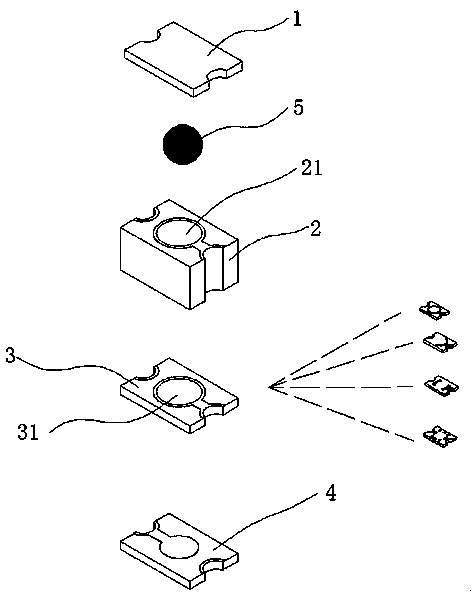

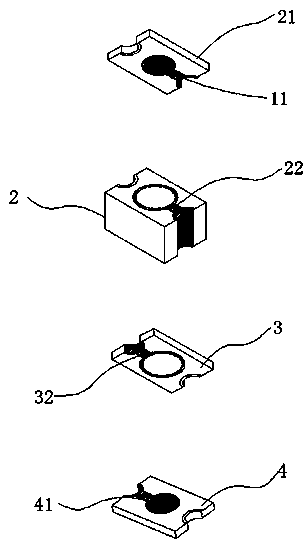

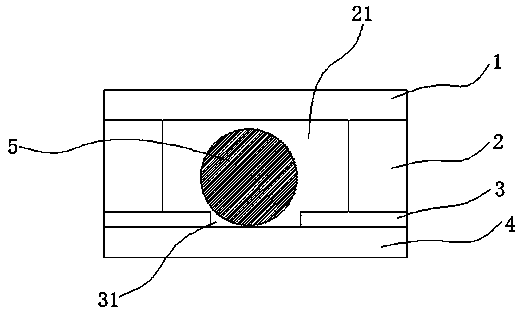

[0040] Example 1, such as Figure 4 and 5As shown, when the patch type tilting ball switch is normally open, the first metal conductive layer 11 and the second metal conductive layer 22 are in contact to form the first electric shock conductor 1a, and the first electric shock conductor is connected to the bottom of the lower cover plate 4 In one of the pads, the third conductive metal layer 32 is arranged on the left side, and the third conductive metal layer 32 is in contact with the fourth conductive metal layer 41 to form a second electric shock conductor 1b, and the second electric shock conductor 1b is connected to the lower cover plate 4 The other pad of the other pad, the conductive ball 5 is only in contact with the second electric shock conductor 1a when placed flat, and the switch is in an open circuit state at this time, that is, it is normally open. The second electric shock conductors 1b are respectively contacted to realize conduction, and at this time, the swit...

Embodiment 2

[0041] Example 2, such as Image 6 and 7 As shown, when the patch type inclined ball switch is normally closed, the first conductive metal layer 11, the second conductive metal layer 22, and the third conductive metal layer 32 are in contact to form the first electric shock conductor 1a, and the first electric shock conductor Connect one of the pads on the bottom of the lower cover plate 4, the first conductive metal layer 11, the second conductive metal layer 22, and the third conductive metal layer 32 are all set on the right side at the same time, and the third conductive metal layer 32 is arranged in a circular shape On the entire inner wall of the small round hole, the fourth metal conductive layer 41 is used alone as the second electric shock conductor 1b, and the second electric shock conductor 1b is connected to another pad of the lower cover plate 4. When the conductive ball 5 is placed flat or the inclination angle is not enough The three metal conductive layers 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com