Rotary tooth type waste film picking machine with self-protection film picking teeth

A film picking tooth and self-protection technology, which is applied in the field of rotary tooth waste film picking machines, can solve the problems of low film picking success rate of the film picking mechanism, large loss of the film picking mechanism, and easy damage of the film picking teeth, so as to improve waste The film pick-up rate, the effect of increasing the service life and reducing the power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

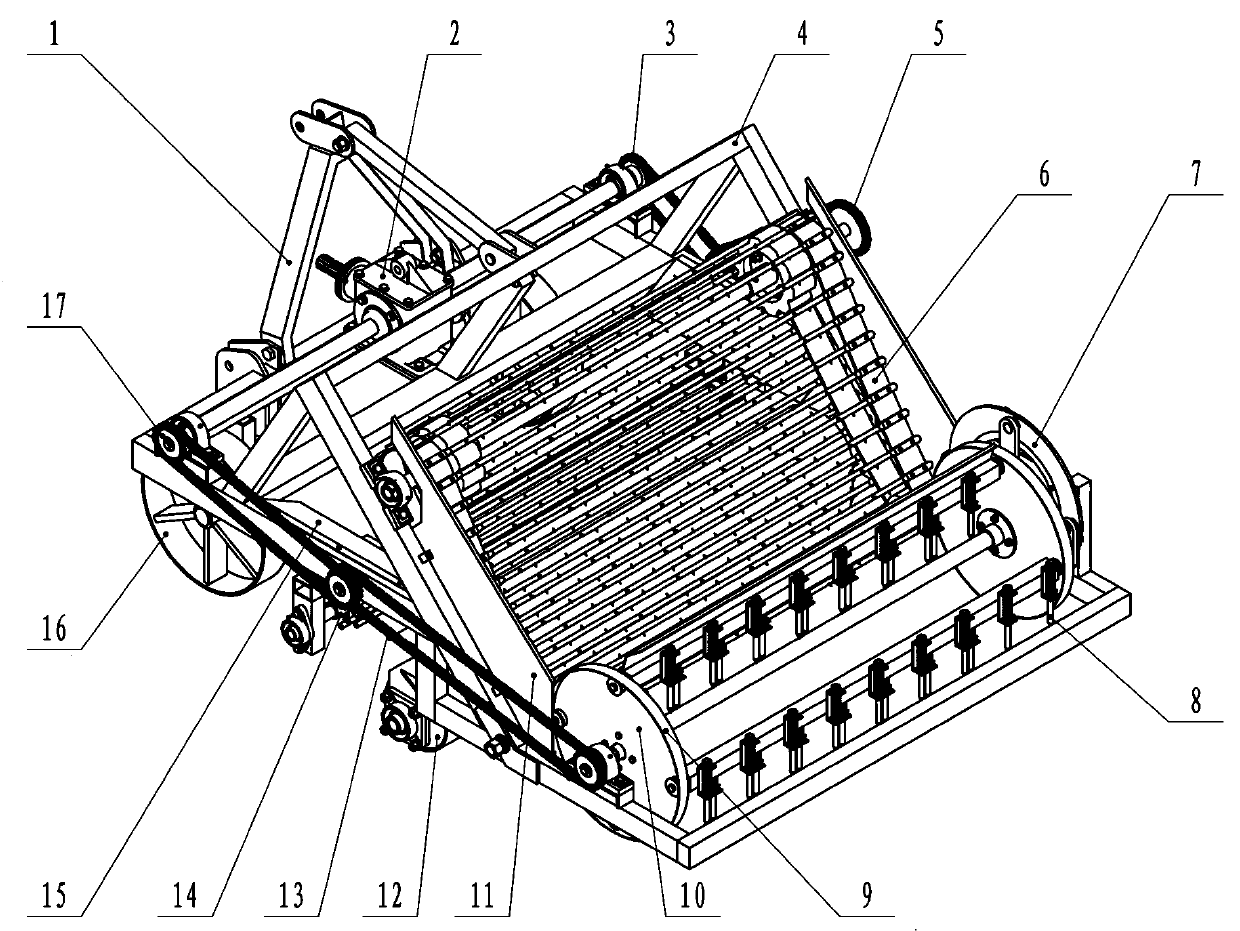

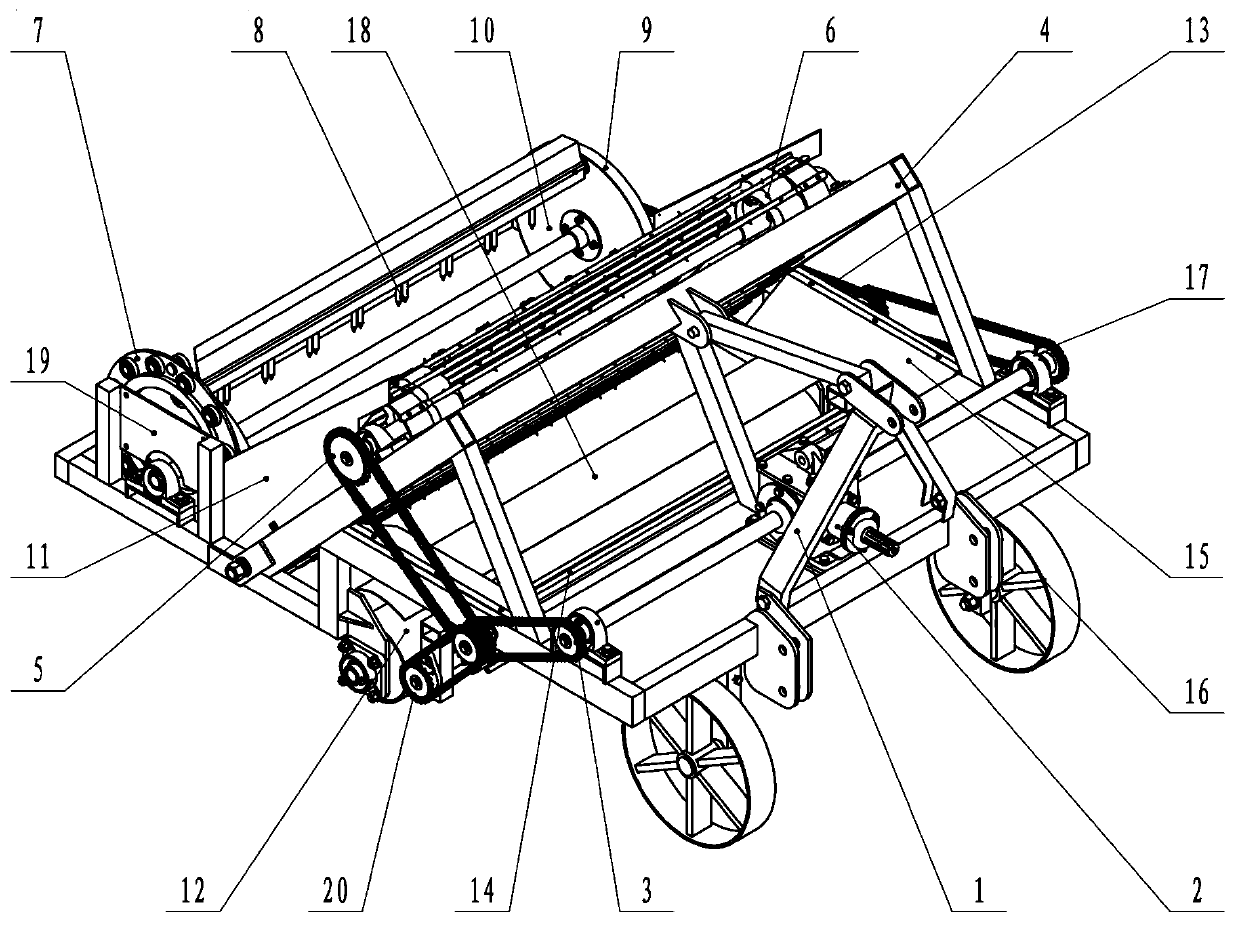

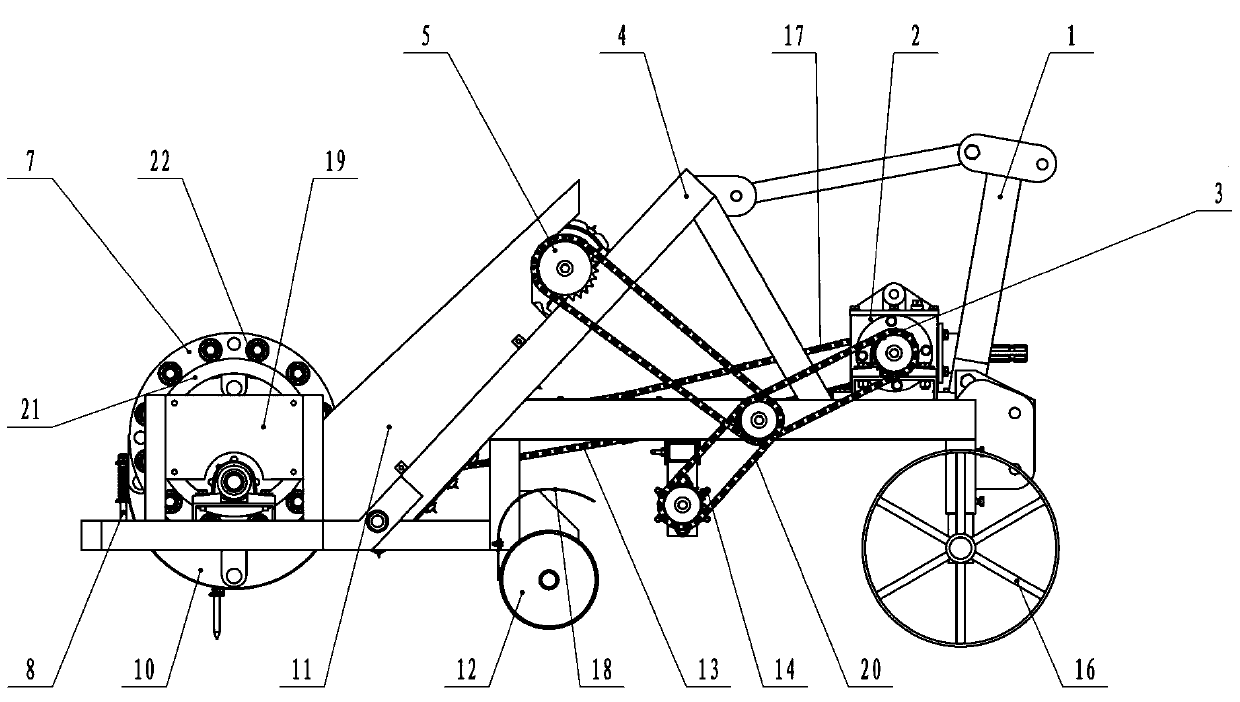

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] as attached figure 1 -Shown in 5, a kind of rotary tooth type waste film pick-up machine with self-protection pick film tooth, comprises traction frame 1, gearbox 2, frame 4, support wheel 16, traction frame 1 and gearbox 2 are installed on the frame 4 Front middle part, support wheel 16 is installed in the front lower part of frame 4, film rolling shaft 14 is installed in the middle and lower part of frame 4, horizontal roller 12 is installed in the middle and lower part of frame 4 behind the film rolling shaft 14, arc-shaped moldboard 18 Installed in the lower part of the frame 4 above the horizontal roller 12, the lower plane of the arc-shaped moldboard 18 is tangent to the rear part of the circumferential surface of the horizontal roller 12, and the upper arc surface of the arc-shaped moldboard 18 is above the horizontal roller 12. Moldboard 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com