Belt guide machine for textile processing

A belt guide and machine body technology, which is applied in the field of belt guide machines for textile processing, can solve the problems of affecting the overall rotation speed of the conveying roller, the inability to automatically tension the guide belt, and poor conveying stability, so that it is not easy to wear and fluff, and avoids falling down. thorn, reduce the effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

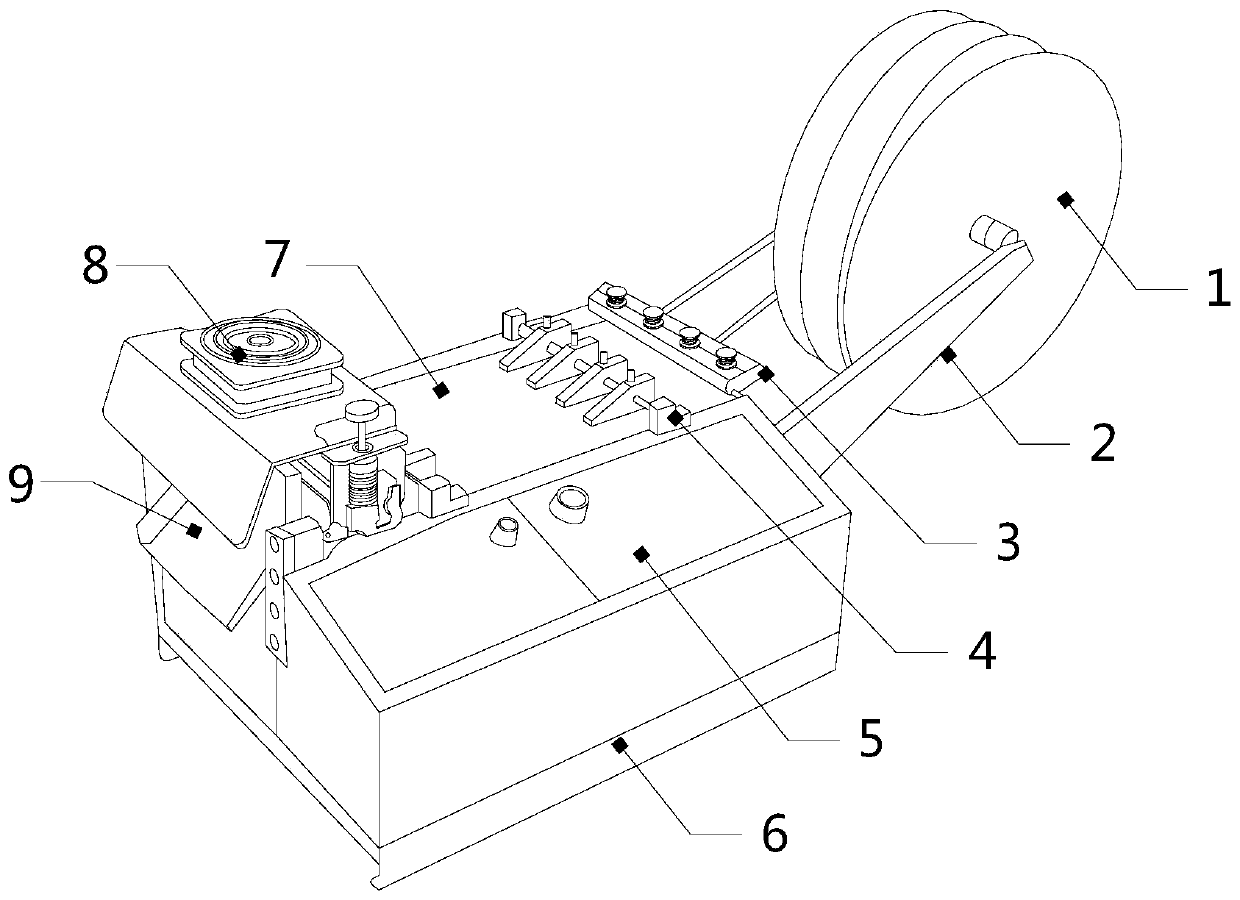

[0027] see Figure 1-Figure 5 , the present invention provides a belt guide machine for textile processing, the structure of which includes a discrete disc 1, a bracket 2, an elastic adjustment mechanism 3, a wire disc 4, a control panel 5, a body 6, a platform 7, a cutting knife 8, and an outlet 9, The top of the body 6 is a platform 7, the two ends of the platform 7 are respectively provided with a wire reel 4 and a cutting knife 8, an outlet 9 is provided directly below the cutting knife 8, and one side of the platform 7 of the body 6 is provided with a Control panel 5, the outer side of the wire reel 4 away from the cutting knife 8 is equipped with a tightness adjustment mechanism 3, and the other side of the tightness adjustment mechanism 3 is equipped with a bracket 2, and the bracket 2 is equipped with more than two discrete disks 1, used to separate the conduction band.

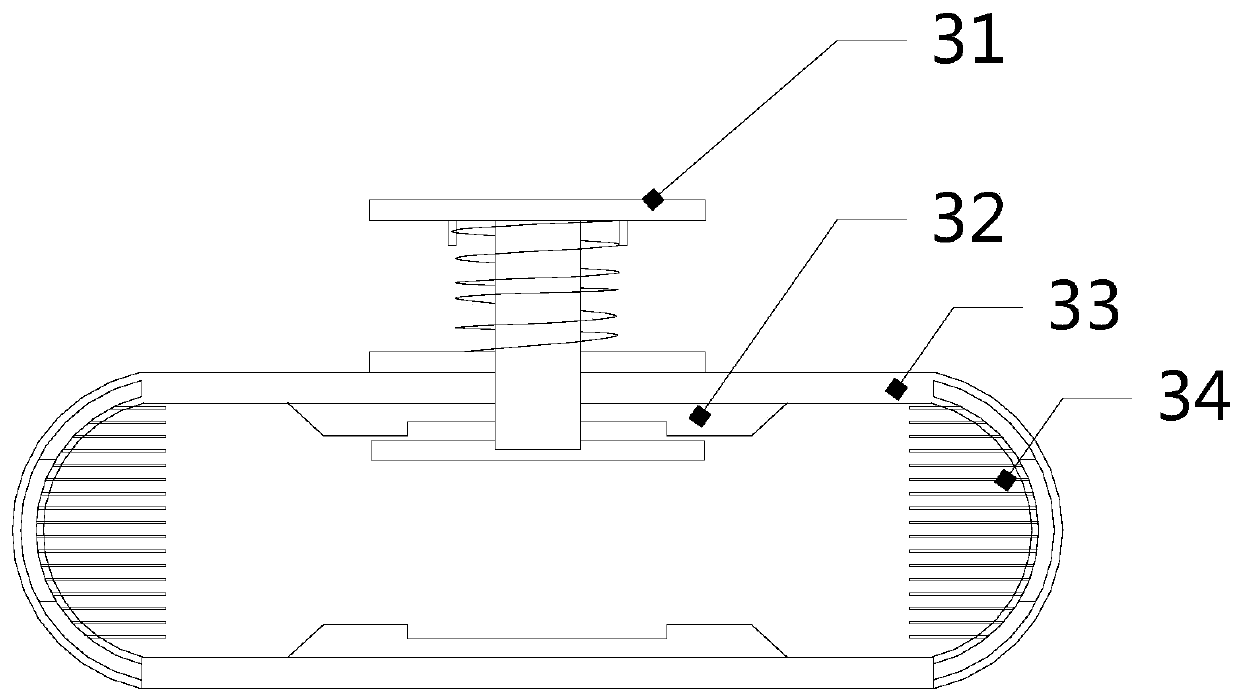

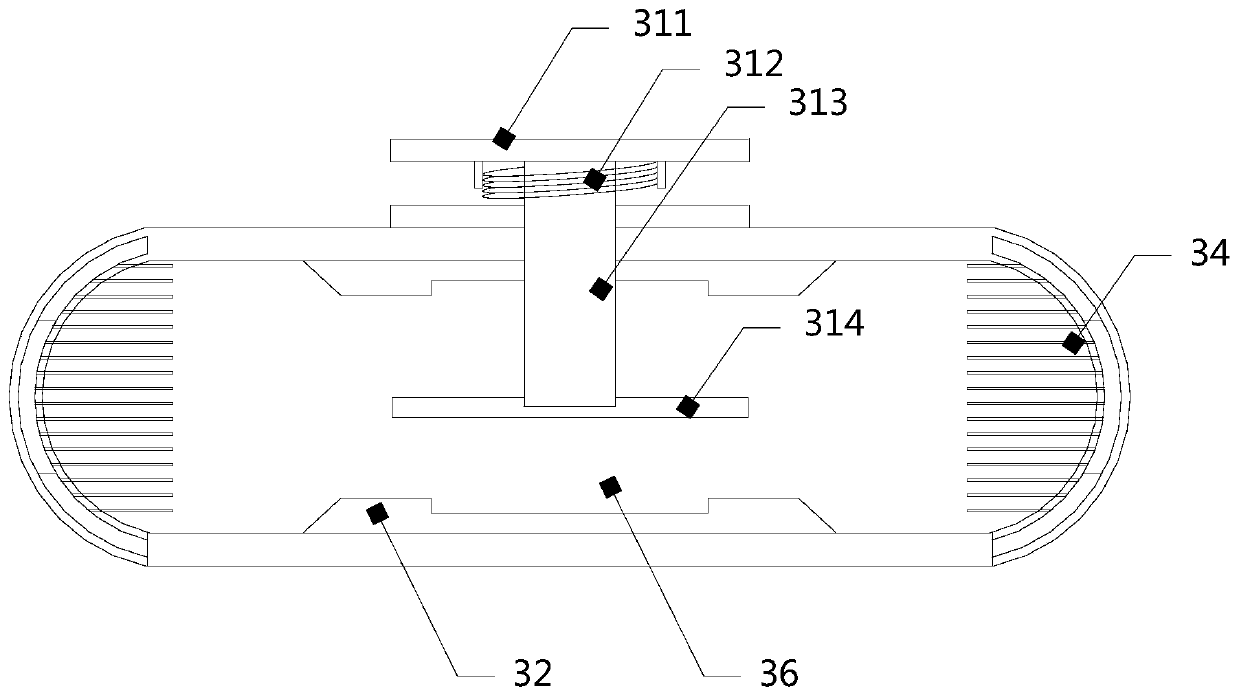

[0028] The tension adjusting mechanism 3 is provided with an elastic device 31 and a casing 33, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com