Method for treating mould in banana pulp processing process

A technology for processing bananas, applied in the field of mold treatment in the banana pulp processing process, can solve the problems of low sterilization efficiency of banana pulp, upper limit of mold killing rate, etc., achieve good appearance, inhibit particle floating, and inhibit oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

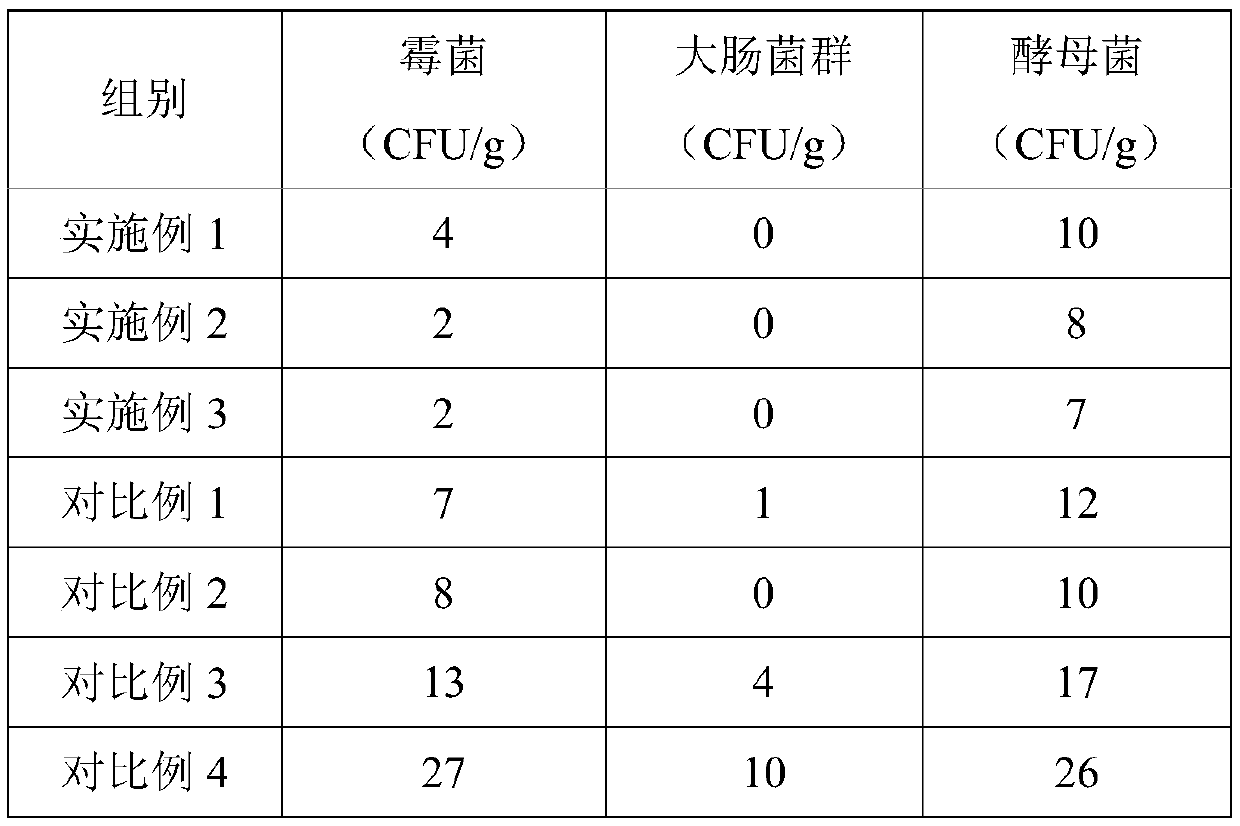

Examples

Embodiment 1

[0025] A method for processing mold during banana pulp processing, the steps comprising:

[0026] S1: Fresh bananas are washed and peeled by a washing machine, put into an enzyme inactivating machine and filled with nitrogen to inactivate enzymes. Microwave is used to inactivate enzymes for 8 minutes. The frequency is 2040MHz, the power is 28Kw, and the air pressure is 0.08 after being filled with nitrogen. Mpa, keep the flow rate at 7cm 3 / min; then use the closed extrusion beater to squeeze the bananas;

[0027] S2: the banana pulp in step S1 is filtered twice, the first filter uses a 70-mesh filter screen, the second filter uses a 270-mesh filter screen, filters and then passes it into a homogenizer, and processes it for 25 minutes at a homogenizing pressure of 12 MPa;

[0028] S3: Then pass the banana pulp into the vacuum tank, and keep the vacuum treatment for 33min at a pressure of -0.013MPa;

[0029] S4: Use ultra-high temperature instantaneous sterilization treatment...

Embodiment 2

[0031] A method for processing mold during banana pulp processing, the steps comprising:

[0032] S1: After the fresh bananas are cleaned and peeled by a cleaning machine, they are put into an enzyme inactivating machine and filled with nitrogen to inactivate enzymes. Microwaves are used to inactivate enzymes for 12 minutes. The frequency is 2340MHz, the power is 33Kw, and the air pressure is 0.14 after being filled with nitrogen. Mpa, keep the flow rate at 7cm 3 / min; then use the closed extrusion beater to squeeze the bananas;

[0033] S2: The banana pulp in step S1 is filtered twice. The first filter uses a 70-150 mesh filter, and the second filter uses a 400 mesh filter. After filtering, pass it into a homogenizer and process it at a homogenizing pressure of 18MPa. 45min;

[0034] S3: Then pass the banana pulp into the vacuum tank, and keep it under the pressure of -0.022MPa for 33min for vacuum treatment;

[0035] S4: Use ultra-high temperature instantaneous sterilizat...

Embodiment 3

[0037] A method for processing mold during banana pulp processing, the steps comprising:

[0038] S1: Fresh bananas are washed and peeled by a washing machine, put into an enzyme inactivating machine and filled with nitrogen to inactivate enzymes. Use microwave to inactivate enzymes for 10 minutes. The frequency is 2280MHz, the power is 31Kw, and the air pressure after filling nitrogen is 0.11 Mpa, keep the flow rate at 7cm 3 / min; then use the closed extrusion beater to squeeze the bananas;

[0039] S2: The banana pulp of step S1 is filtered twice, the first filter uses a 120-mesh filter screen, the second filter uses a 325-mesh filter screen, filters and then passes it into a homogenizer, and processes it at a homogenizing pressure of 14 MPa for 33 minutes;

[0040] S3: Then pass the banana pulp into the vacuum tank, and keep it under the pressure of -0.020MPa for 23min for vacuum treatment;

[0041] S4: Use ultra-high temperature instantaneous sterilization treatment, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com