Material carrying device with lifting function

A technology for handling devices and materials, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., which can solve the problems of production inconvenience and achieve the effect of lifting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

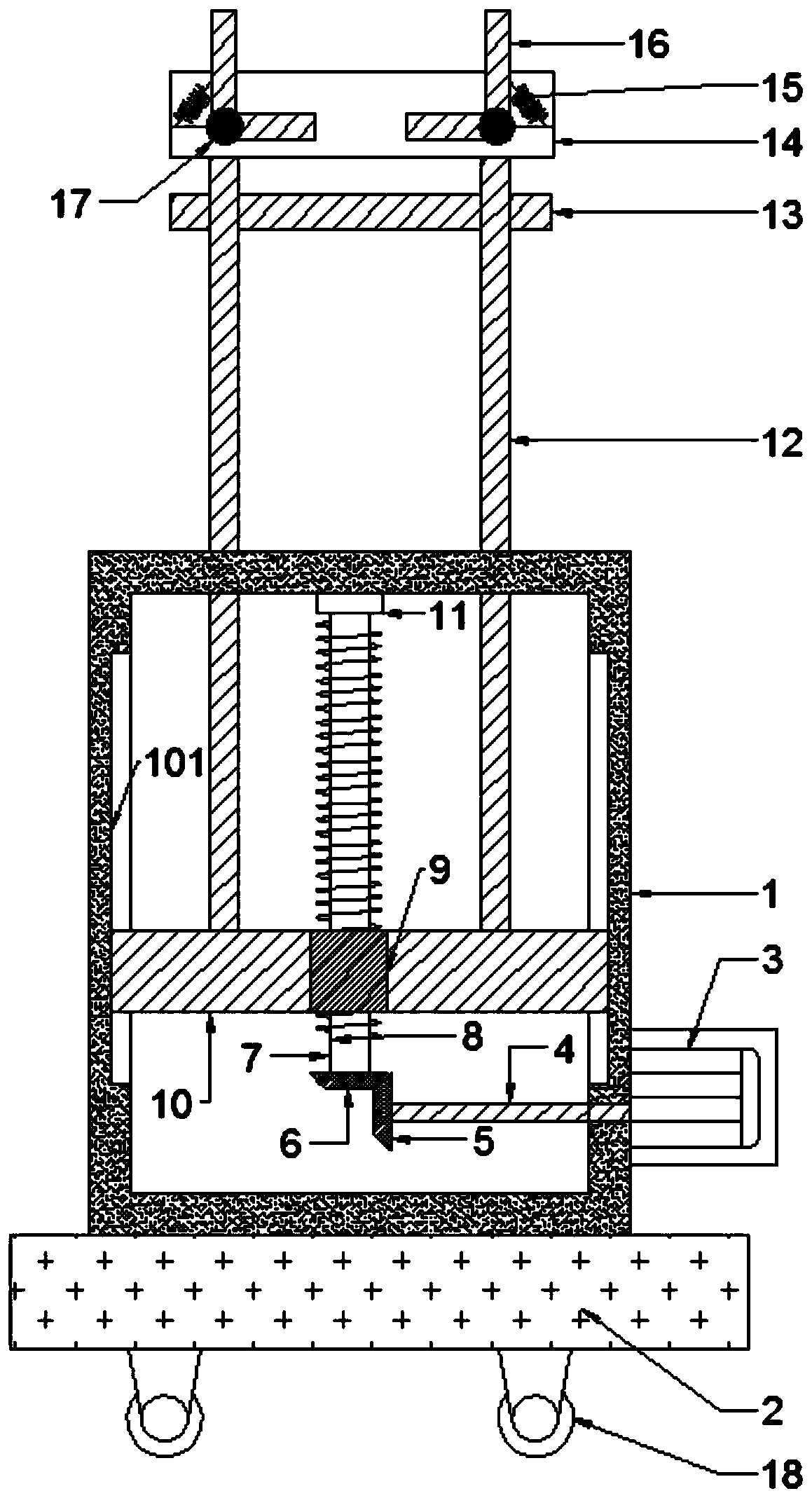

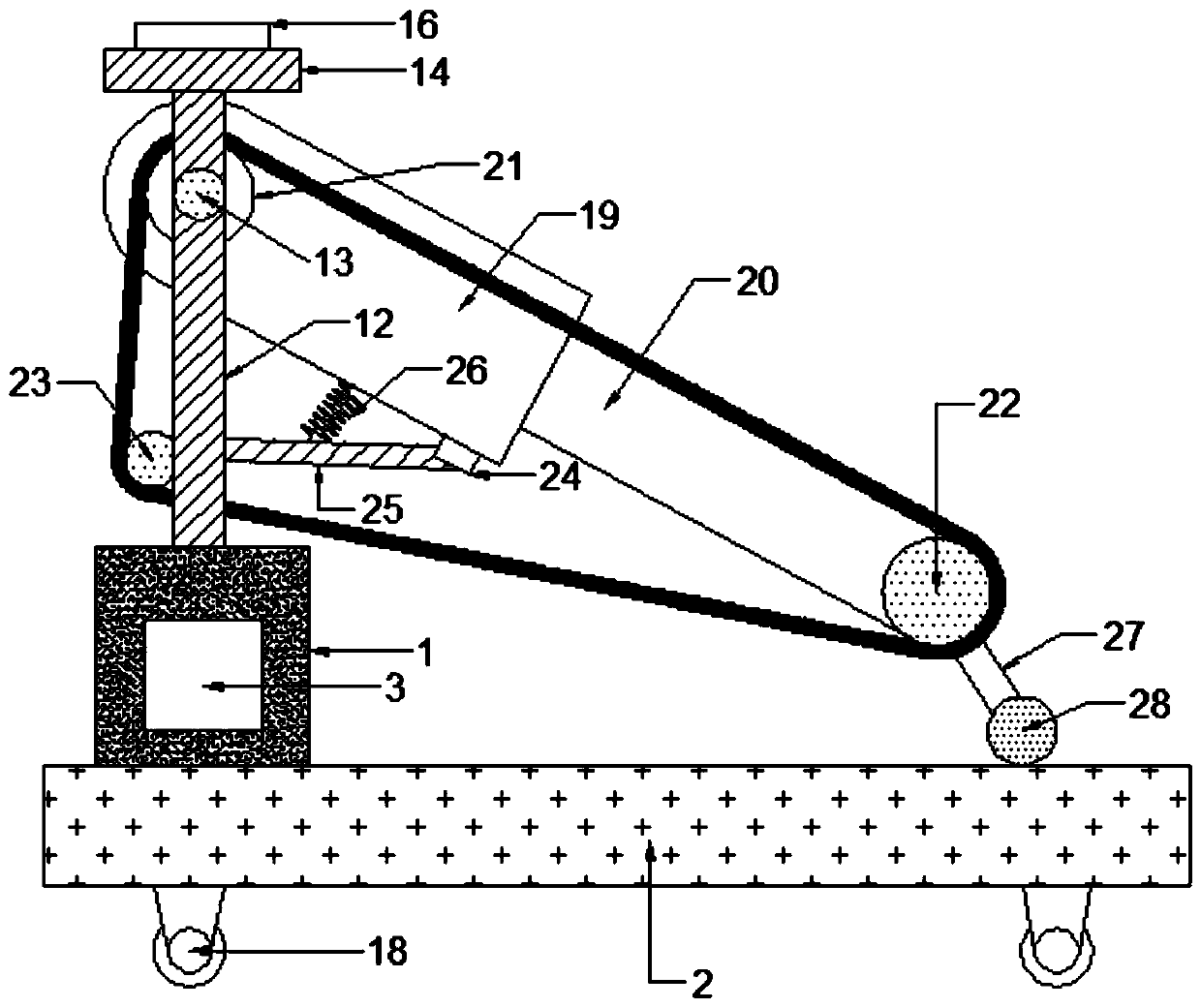

[0021] see Figure 1~3 , in an embodiment of the present invention, a lifting material handling device includes a housing 1 and a base 2, and also includes a lifting assembly and a transmission assembly. The lifting assembly includes a motor 3, a rotating shaft 4, a first bevel gear 5, a second bevel gear 6. Turning rod 7, thread 8, sliding block 9, sliding rod 10, upper fixing block 11, fixing rod 12 and mounting rod 13, housing 1 is set on base 2, motor 3 is fixedly installed on the outside of the side wall of housing 1 , the output end of the motor 3 is located inside the housing 1 and the rotating shaft 4 is installed, the outermost end of the rotating shaft 4 is installed with the first bevel gear 5, the first bevel gear 5 and the second bevel gear 6 are connected through gear fit, the second bevel gear The top of 6 is connected with the rotating rod 7, and the upper part of the rotating rod 7 is fixedly installed in the inside of the housing 1 through the upper fixed blo...

Embodiment 2

[0027] In order to diversify the functions of the lifting material handling device, this embodiment is further improved on the basis of Embodiment 1. Two fixed rods 12 above the mounting rod 13 are provided with mounting plates 14; Two fixed rods 12 are provided with mounting plates 14, so that goods can be stored on the mounting plates 14, which is convenient for the staff at high places to carry out further work.

[0028] A limiting plate 16 is installed above the mounting plate 14, and the bottom end of the limiting plate 16 is connected with the mounting plate 14 by a hinge 17, and the top of the limiting plate 16 is connected with the mounting plate 14 by the first elastic member 15; A limiting plate 16 is installed above the mounting plate 14, and the bottom end of the limiting plate 16 is connected with the mounting plate 14 by a hinge 17, and the top of the limiting plate 16 is connected with the mounting plate 14 by the first elastic member 15, and the mounting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com