Photothermal heat exchanger shell pass sealing device

A heat exchanger shell side and sealing device technology, applied in the direction of heat exchanger shell, heat exchange equipment, solar collectors, etc., can solve the problems of fatigue life difficult to meet the design requirements, fluid short circuit, etc., to meet the requirements of disassembly and assembly Maintenance requirements, avoid stress concentration, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

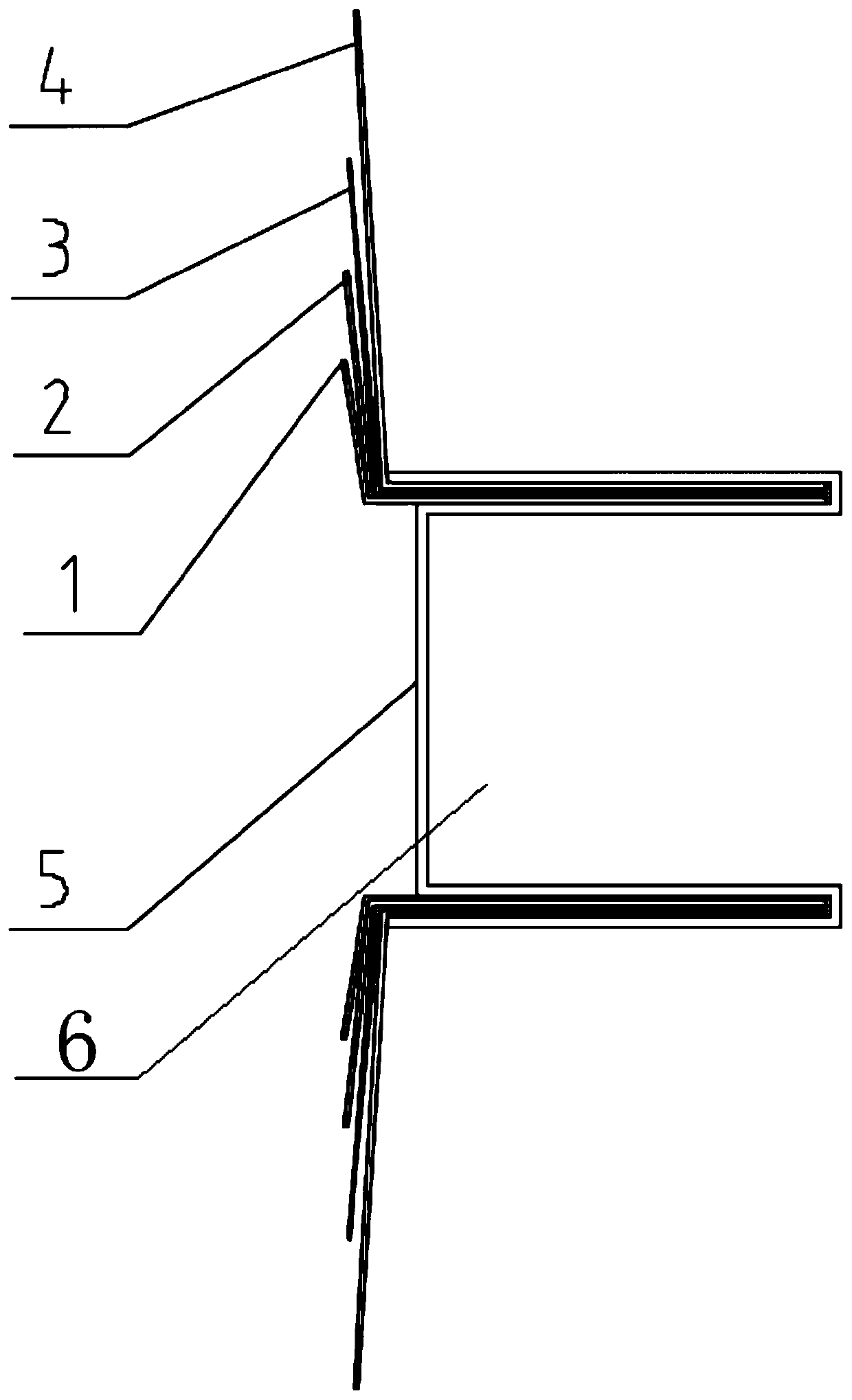

[0019] Such as figure 1 As shown, a kind of suitable shell-side medium provided for this embodiment is high-temperature molten salt (60wt%NaNo 3 +40wt% KNO 3 ) shell-side sealing device of the light-to-heat heat exchanger, which includes an M-shaped groove 5, the middle groove of the M-shaped groove 5 is matched with the partition plate 6, and four sealing sheets with a bending structure are respectively arranged in the grooves on both sides. One edge of the sealing sheet is set in the groove of the M-shaped groove 5 , and the other edge is set outside the groove of the M-shaped groove 5 and extends to the outside of the partition plate 6 . Arranged in order from the separator 6 to both sides are sealing sheet 1 with a bending angle of 120 ゜, sealing sheet 2 with a bending angle of 116 ゜, sealing sheet 3 with a bending angle of 112 ゜ 3, and sealing sheet with a bending angle of 108 ゜ Seal sheet 44. Under the action of the partition's own weight, the sealing sheet is attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com