Patents

Literature

31results about How to "Elimination of welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

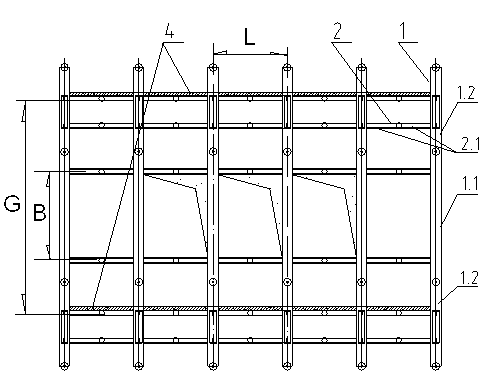

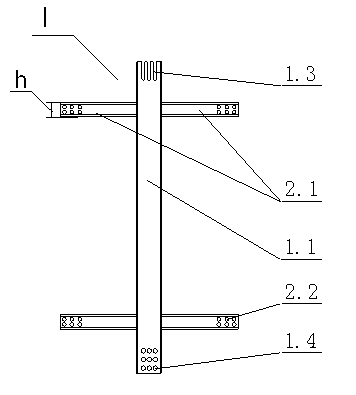

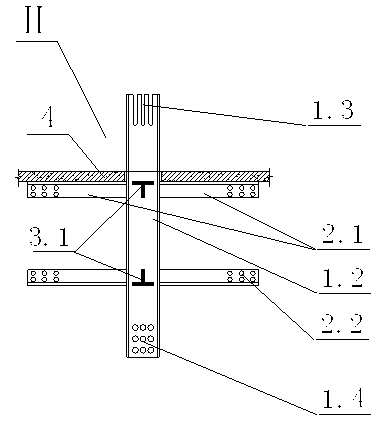

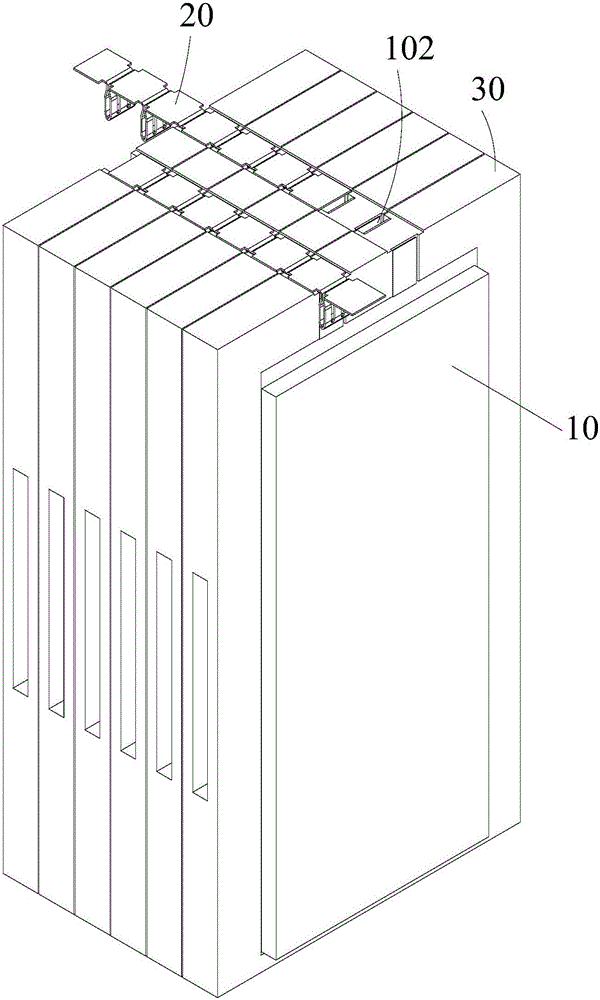

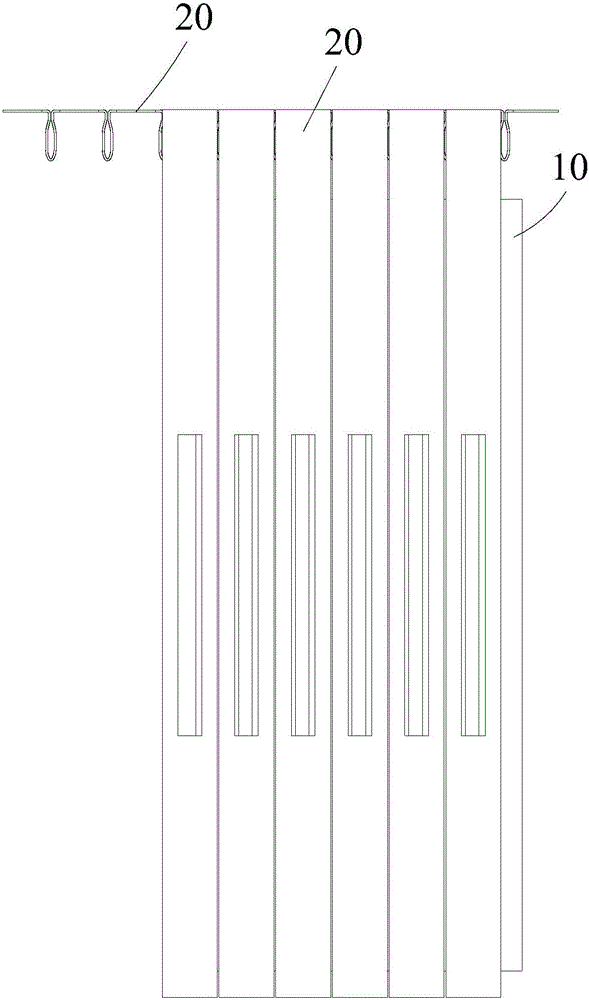

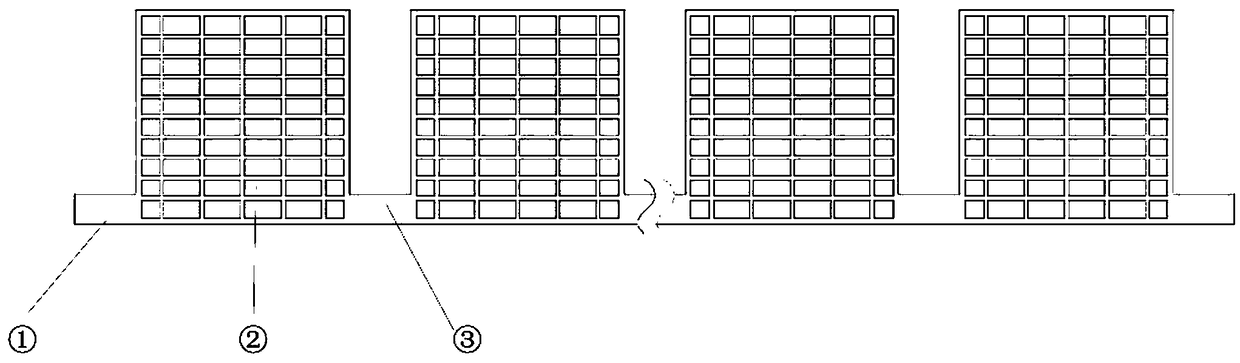

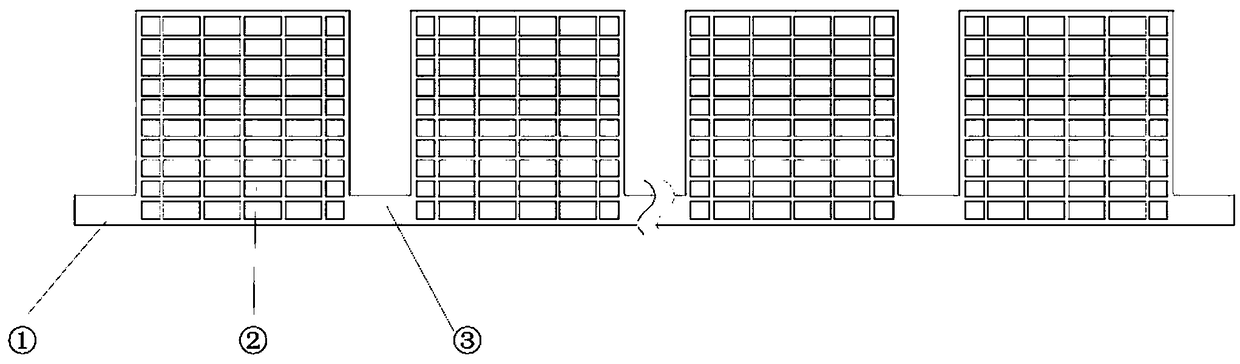

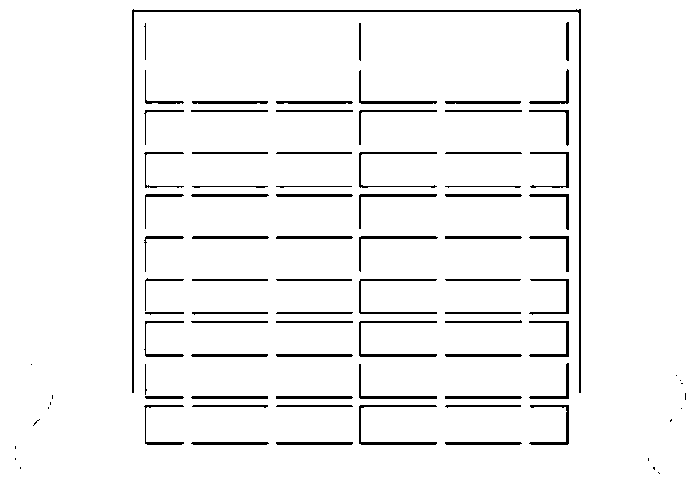

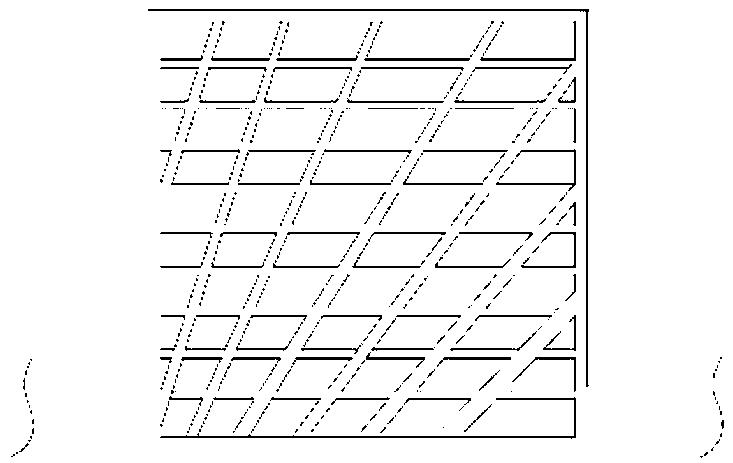

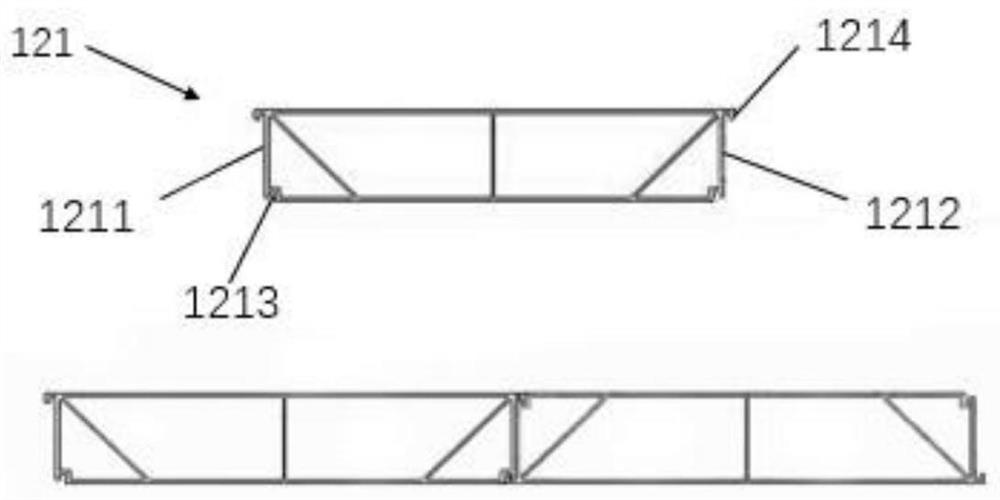

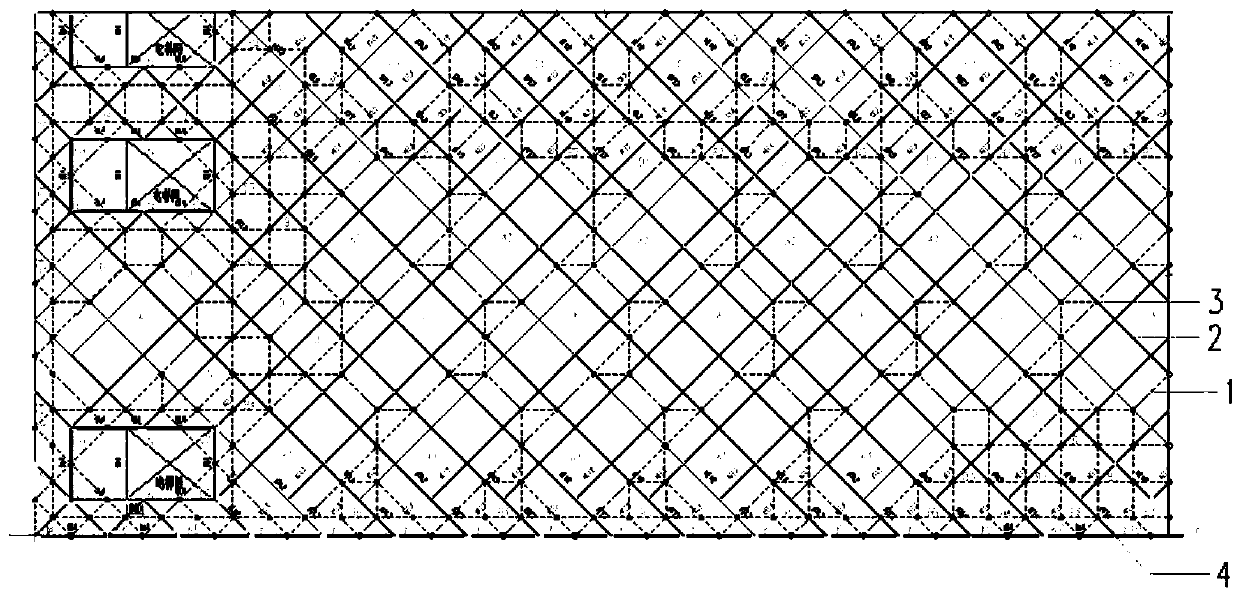

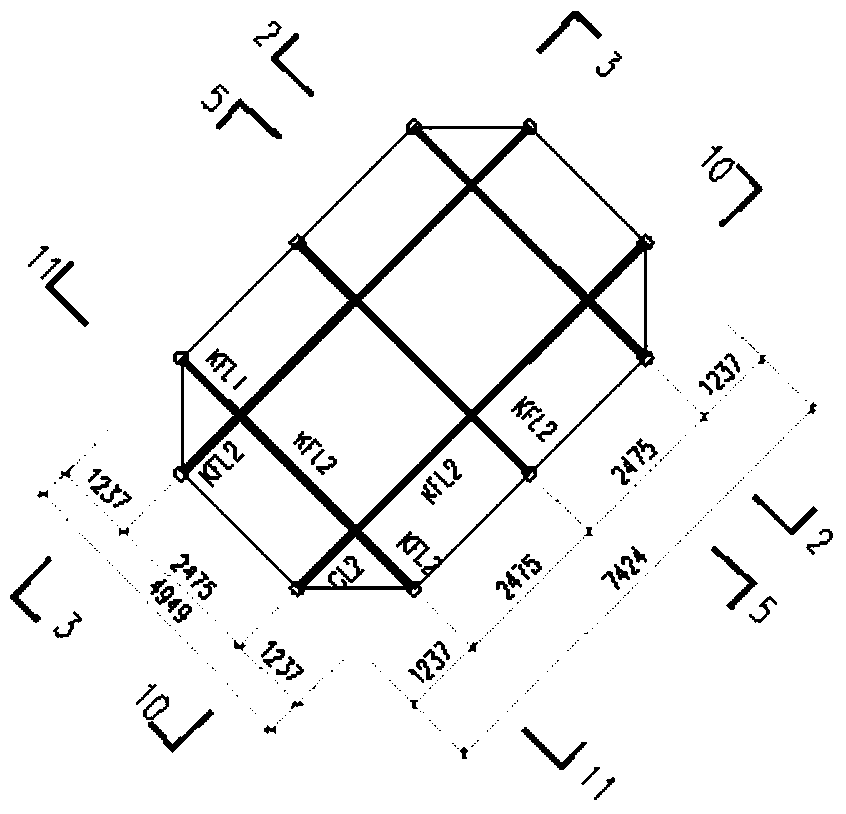

Multilayer large-span assembling integral type space steel grid building structure and manufacturing method

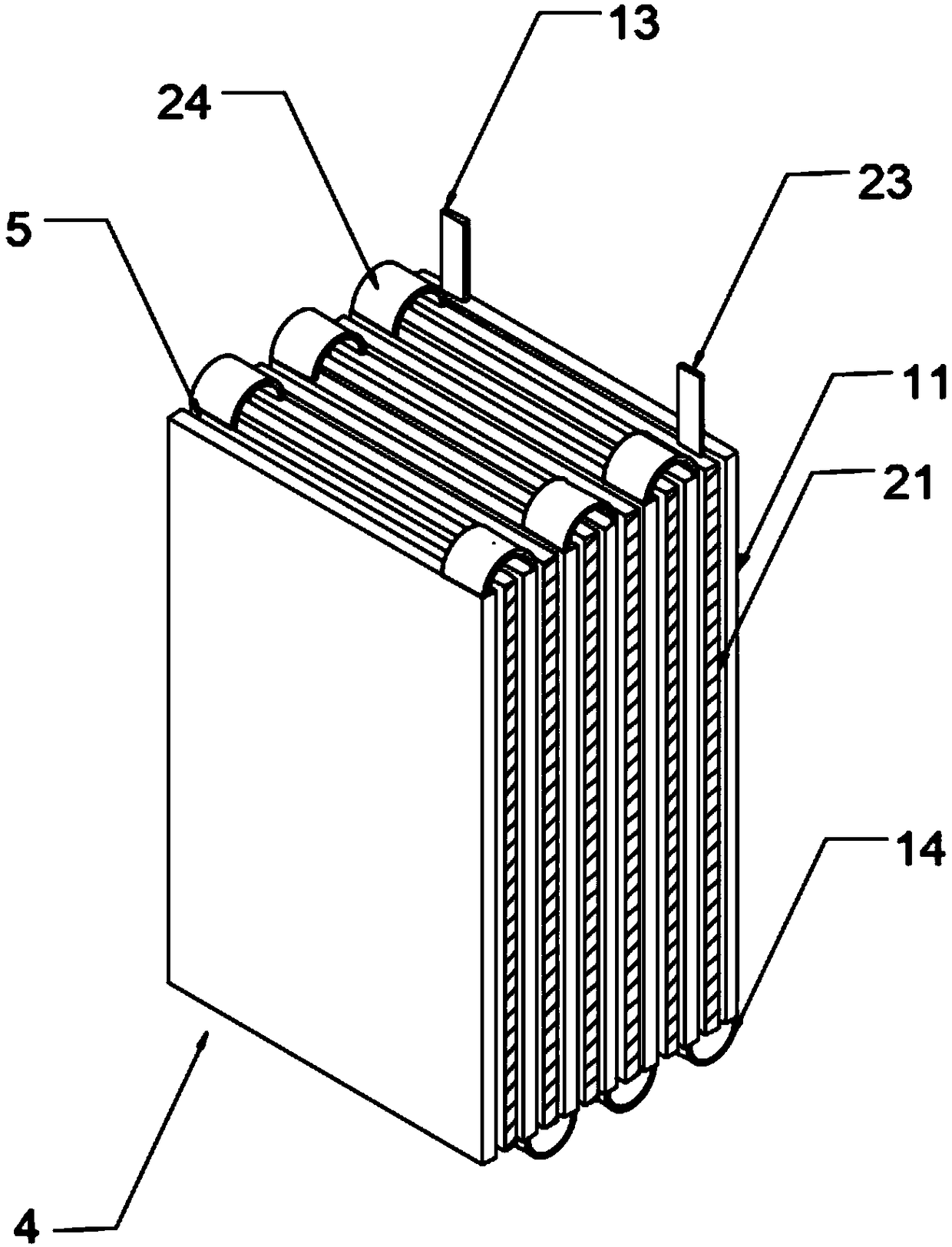

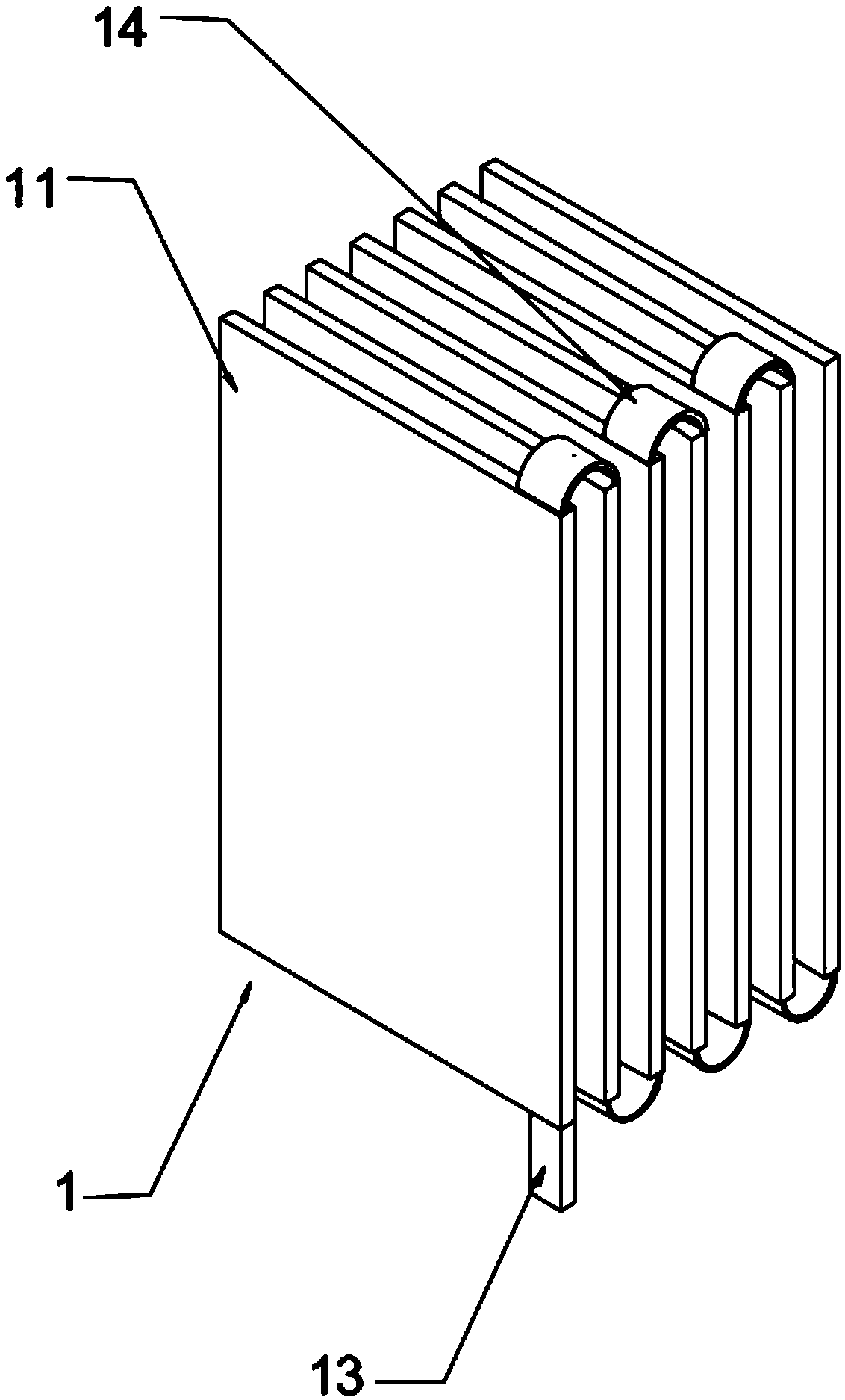

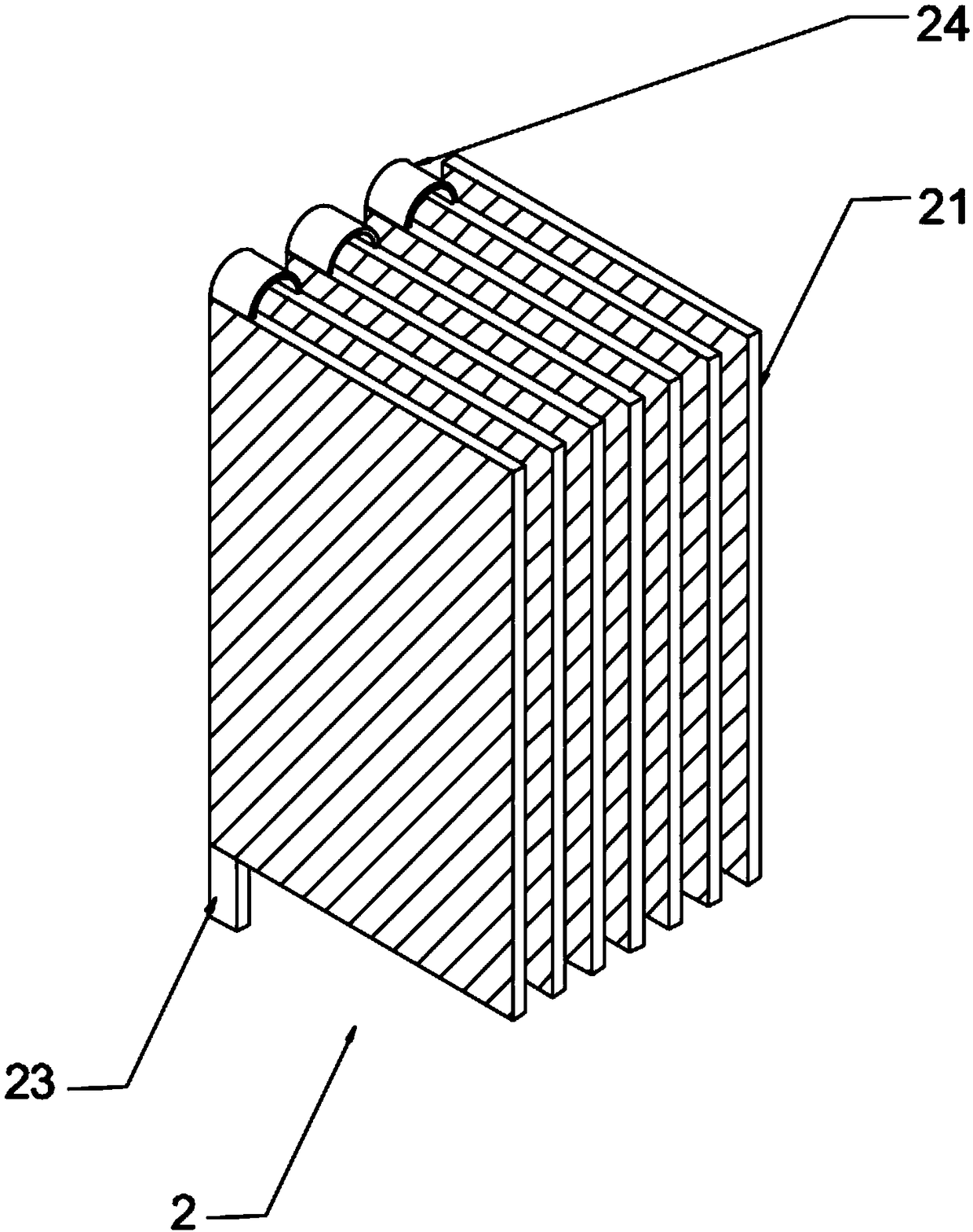

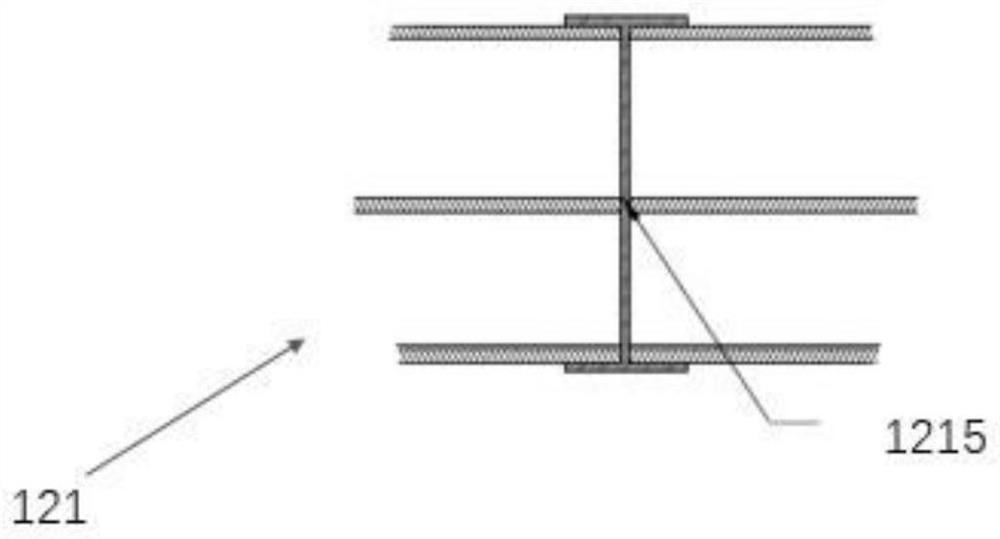

The invention discloses a multilayer large-span assembling integral type space steel grid building structure and a manufacturing method. The multilayer large-span assembling integral type space steel grid building structure is formed by adopting a steel grid type bearing outer wall structure and an assembling integral plated type or curved surface type steel hollow grid structure as a floor cover or a house cover structure to be assembled; the steel grid type bearing outer wall structure is formed by connecting a combined upright columns manufactured by rectangular steel tubes and combined transverse beams manufactured by H-shaped steel or T-shaped steel; the rectangular shape of the upright column is 200-300mm in height or width; the wall thickness of the upright column is 4-10mm; the shape height of the H-shaped steel or T-shaped steel of the transverse beam is 100-200mm; the center distance between every two adjacent upright columns is 1500-4000mm; and five transverse beams are connected in a column net structure within each height range and between two adjacent upright columns. The multilayer large-span assembling integral type space steel grid building structure has the advantages of being light in weight, high in strength, easy to construct, good in quality and the like.

Owner:HUNAN UNIV +4

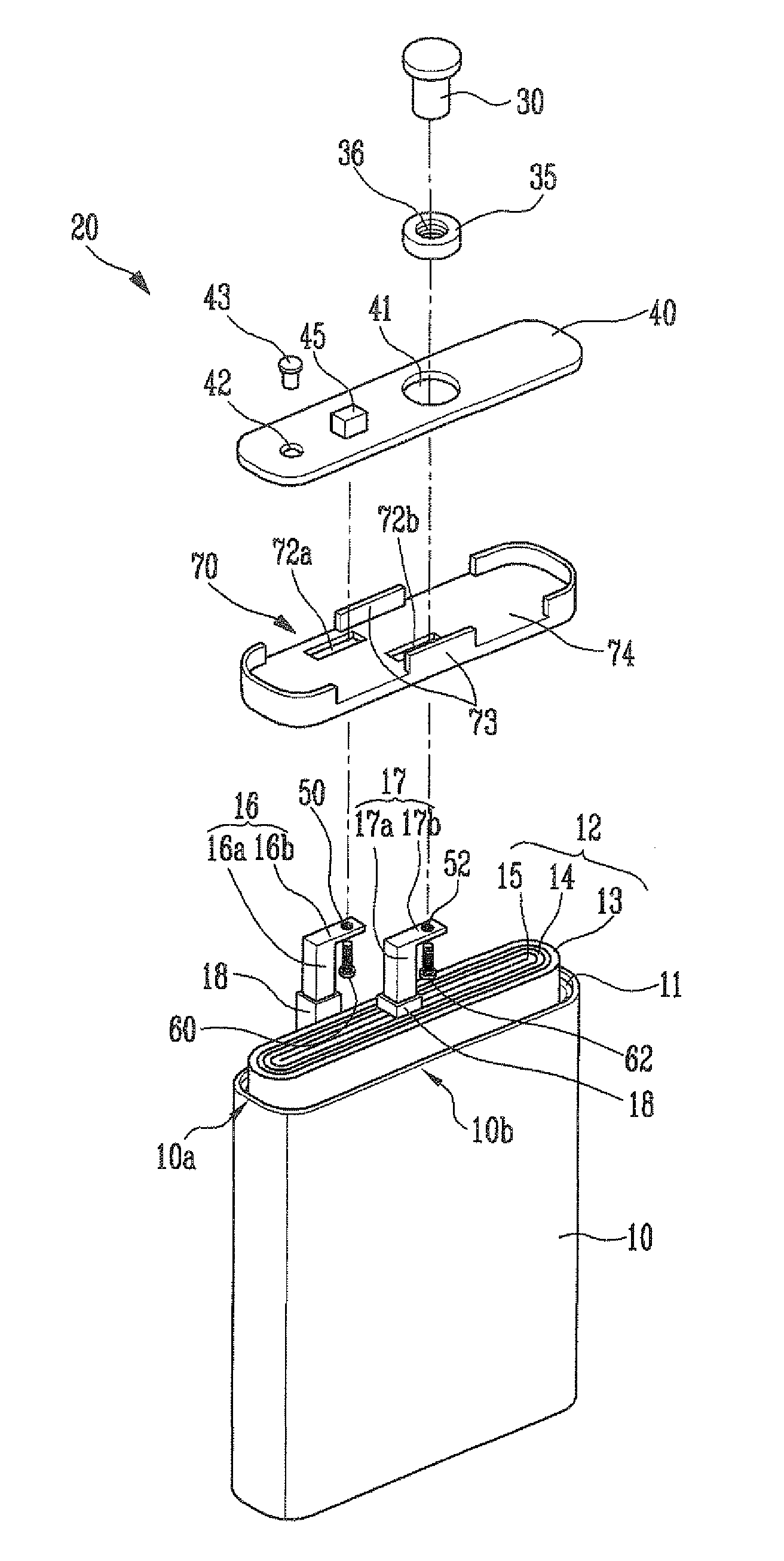

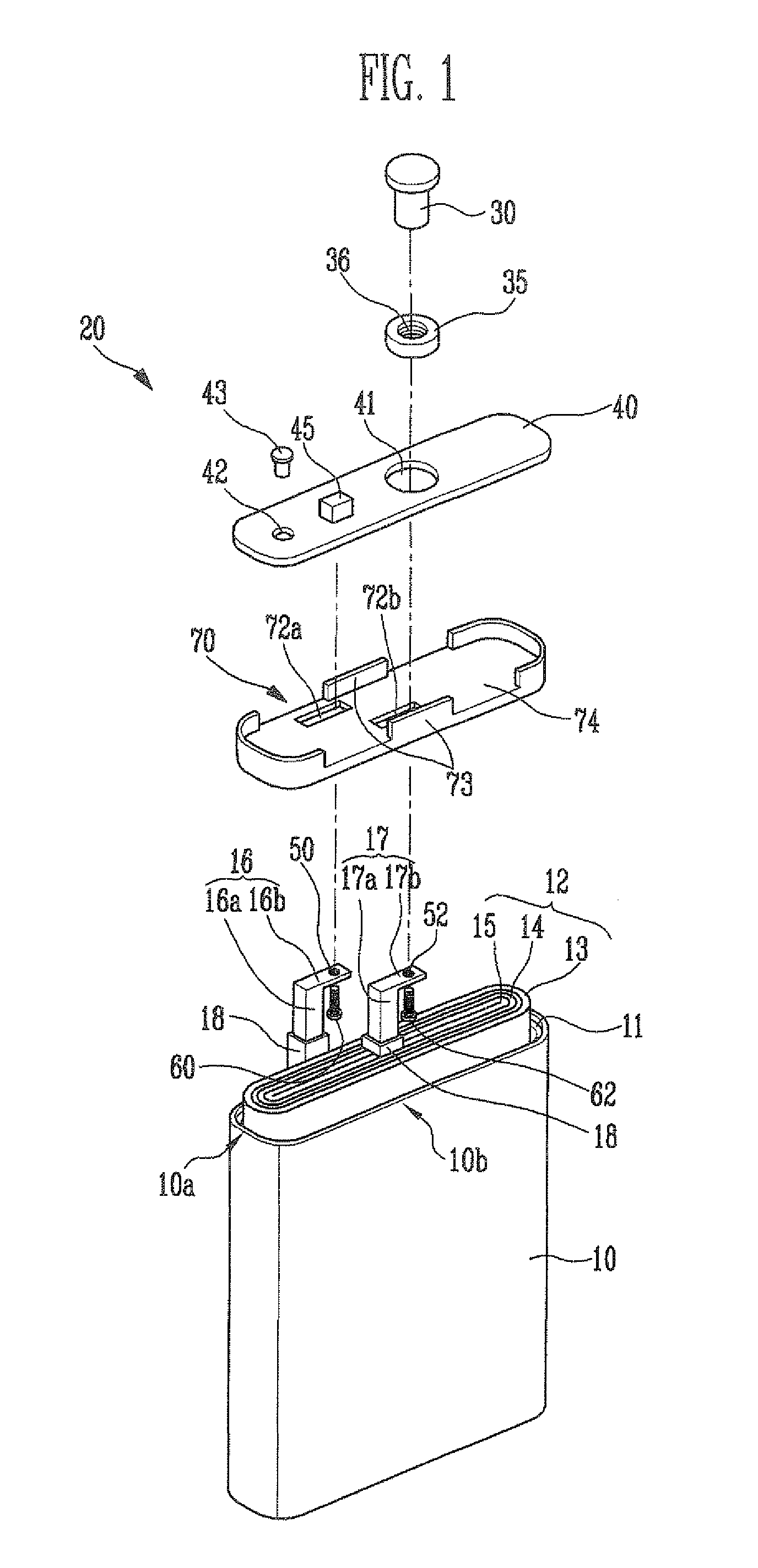

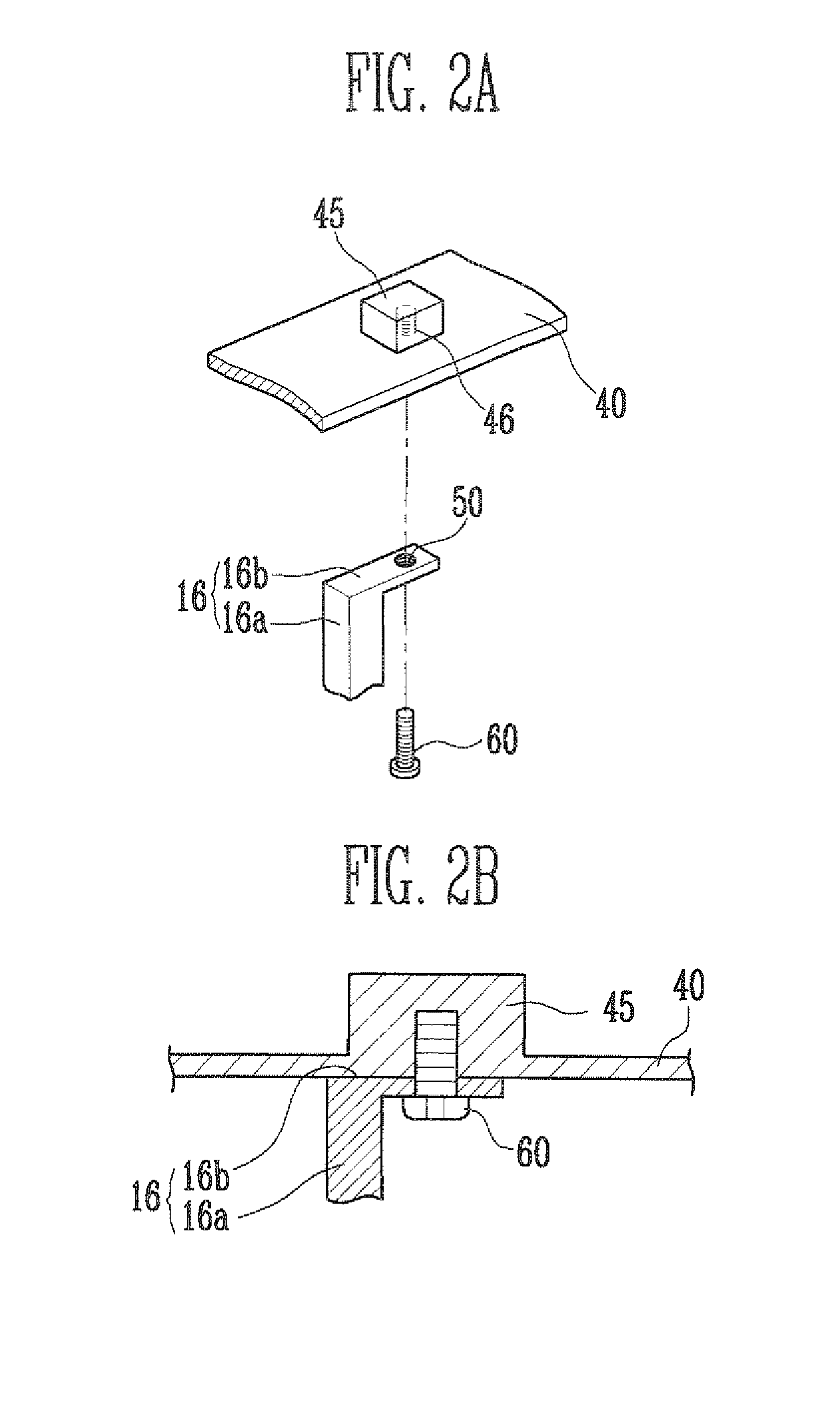

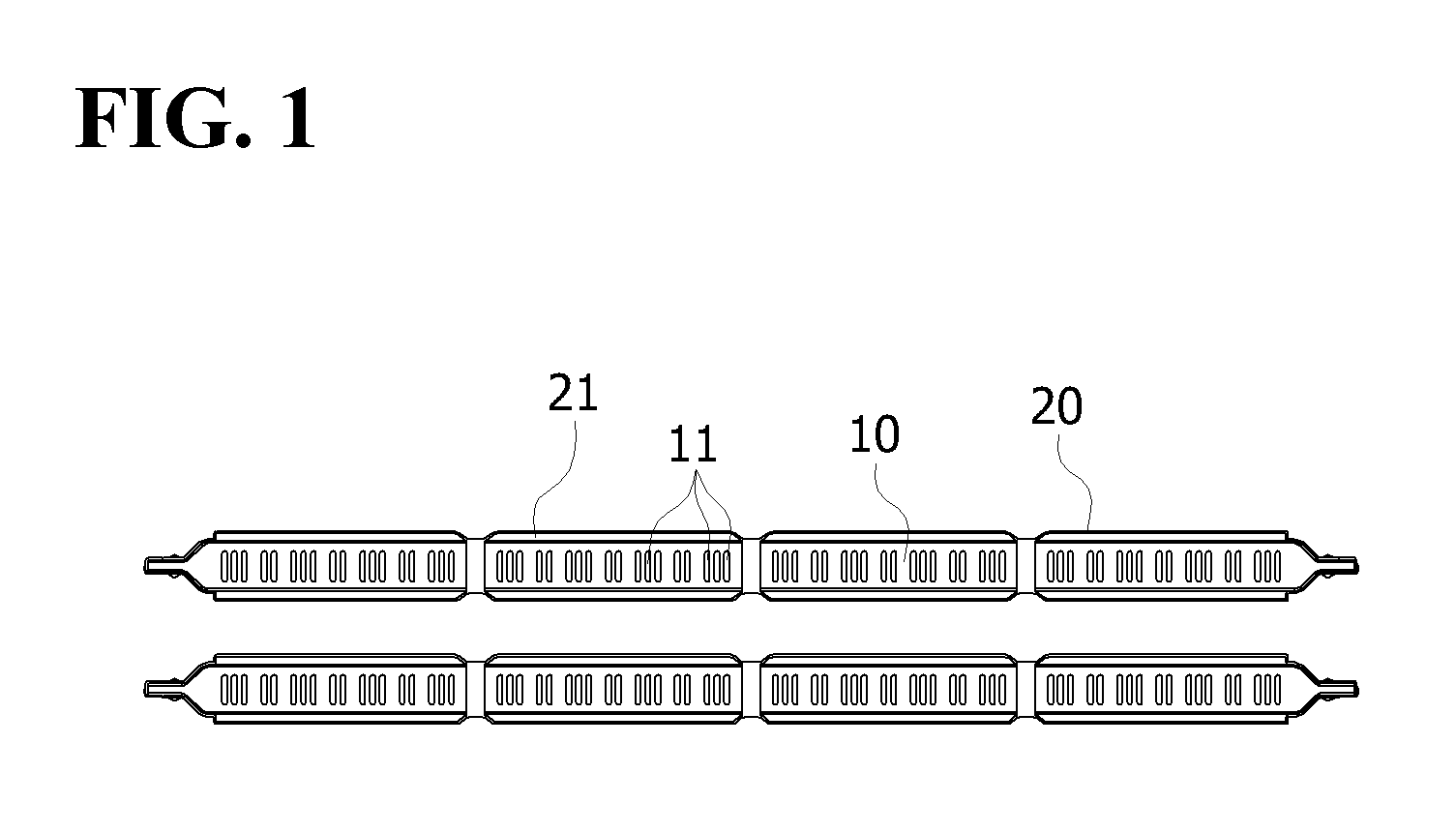

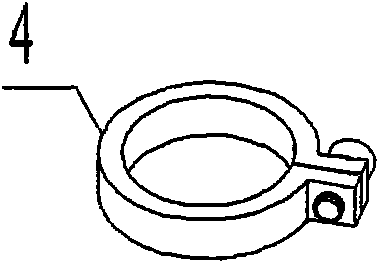

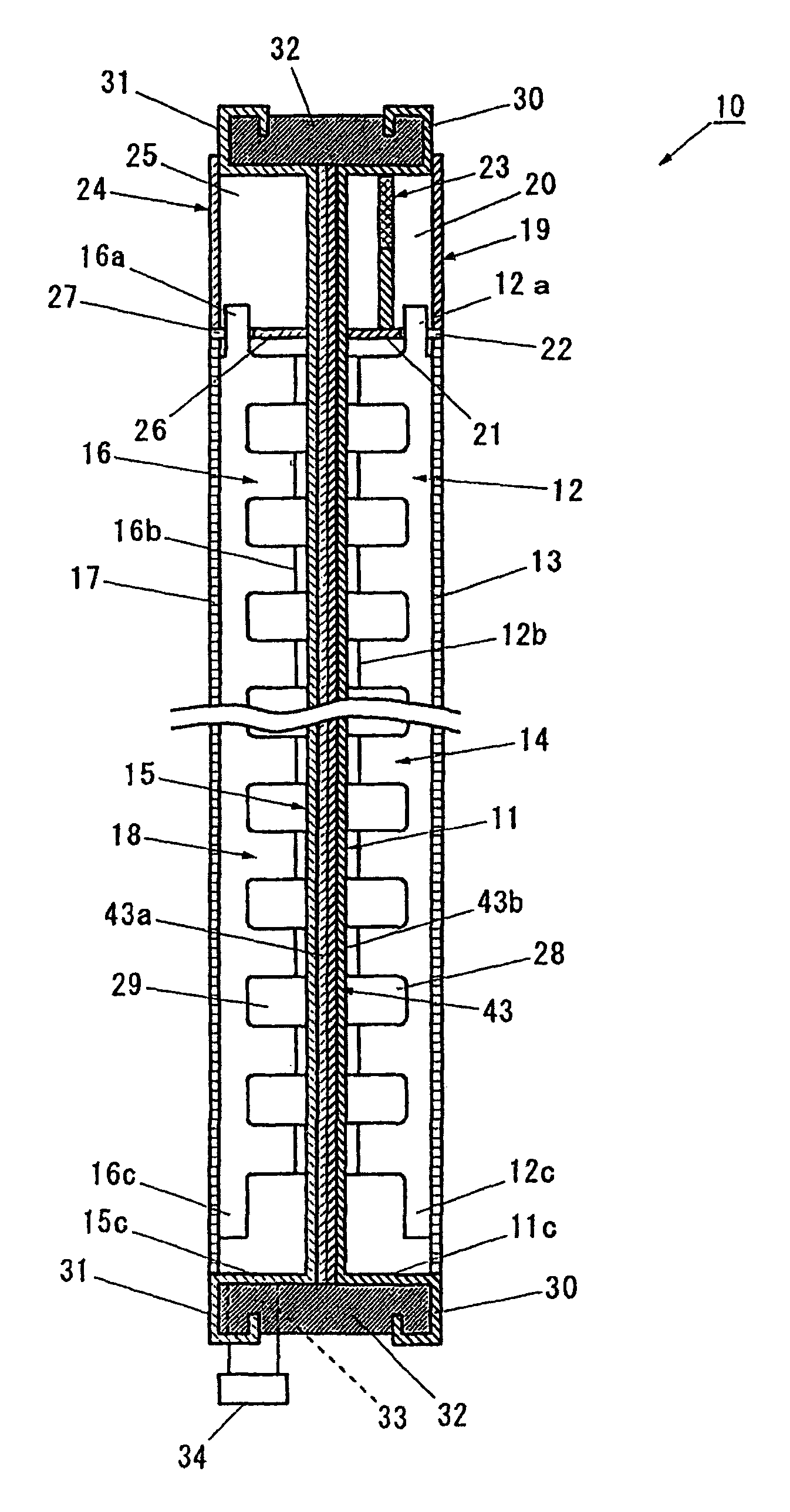

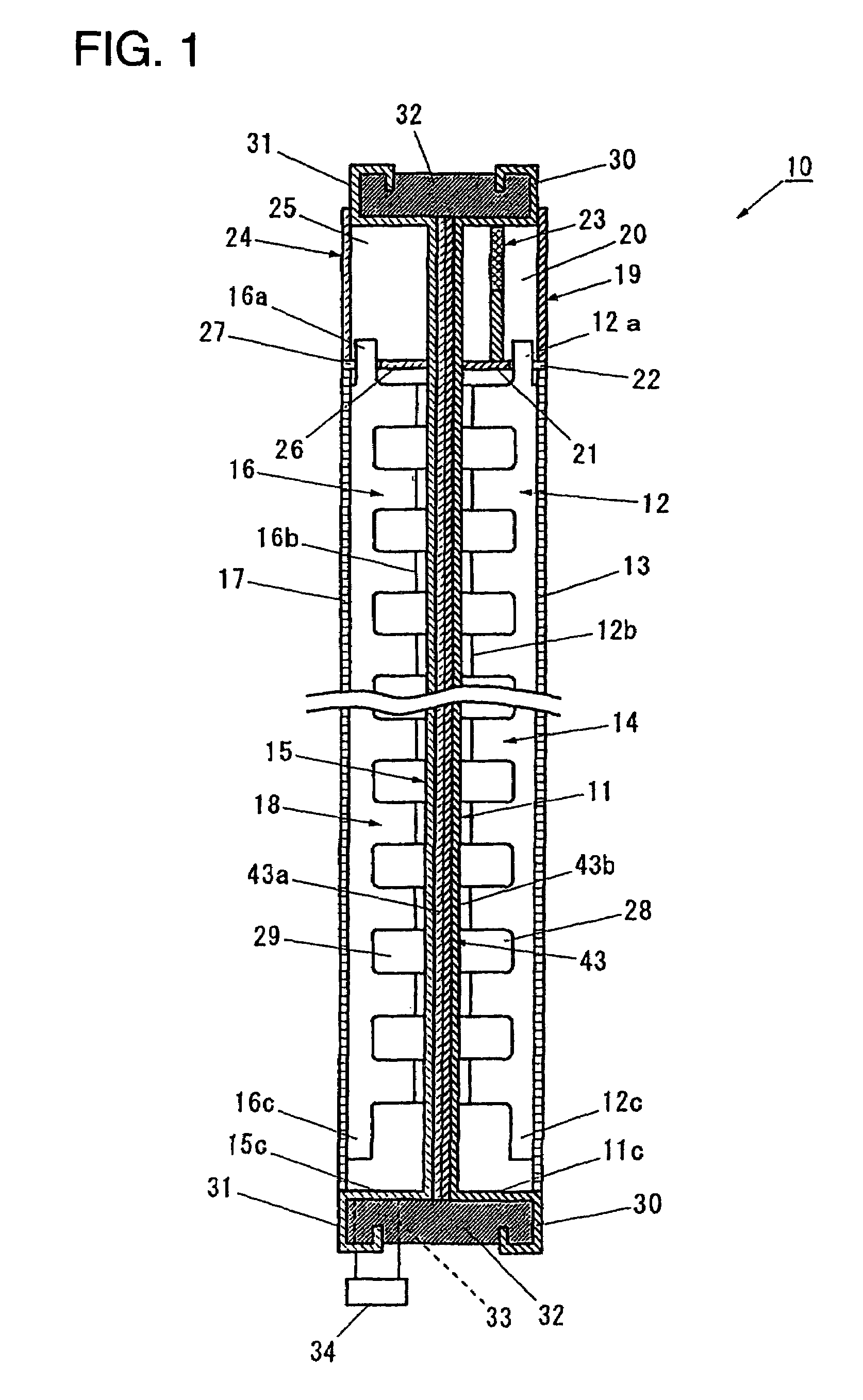

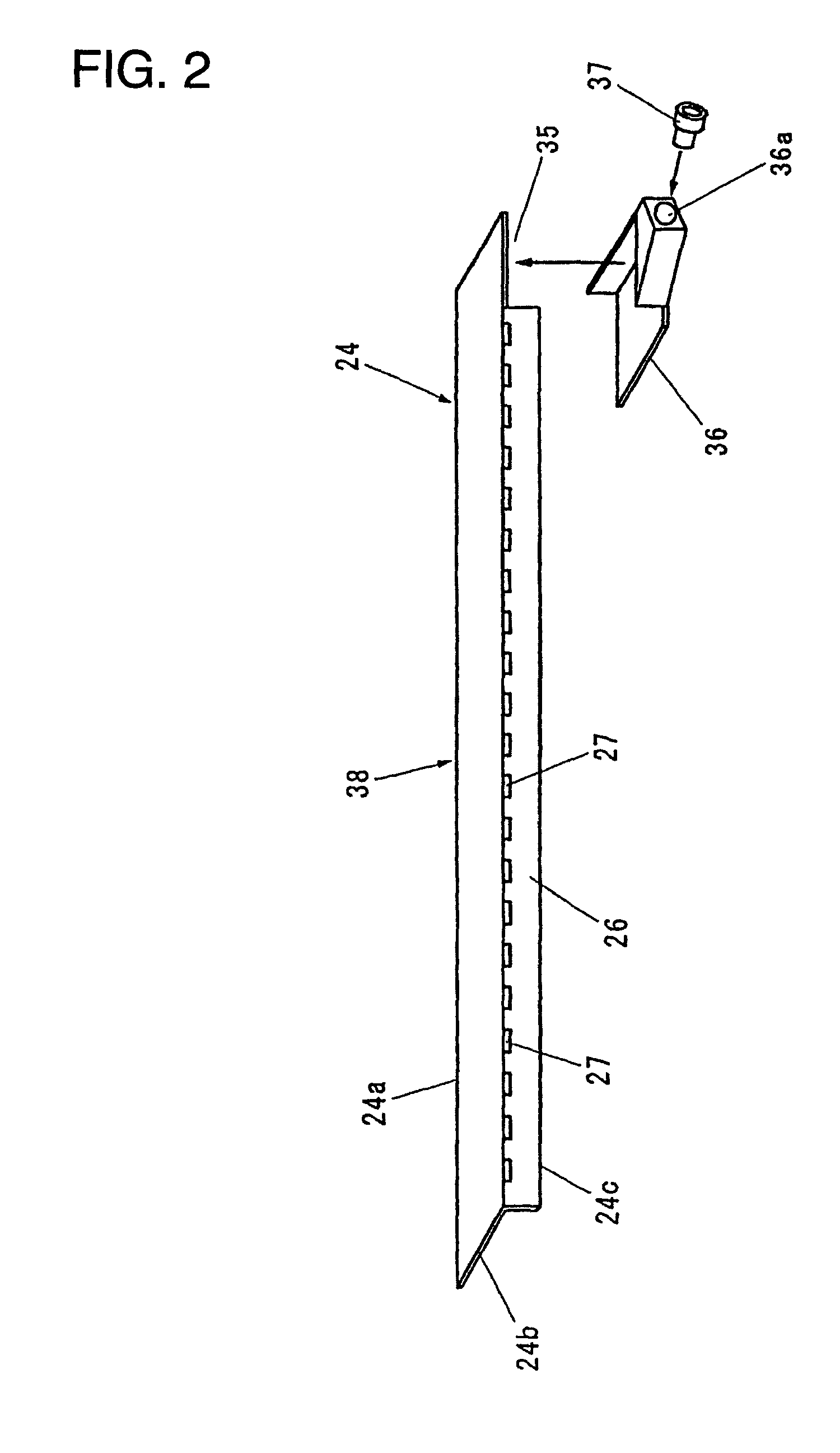

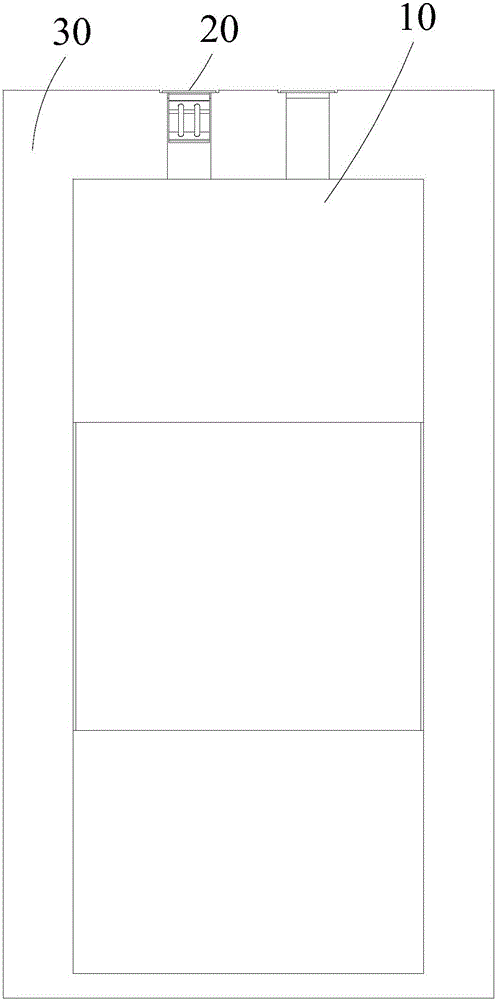

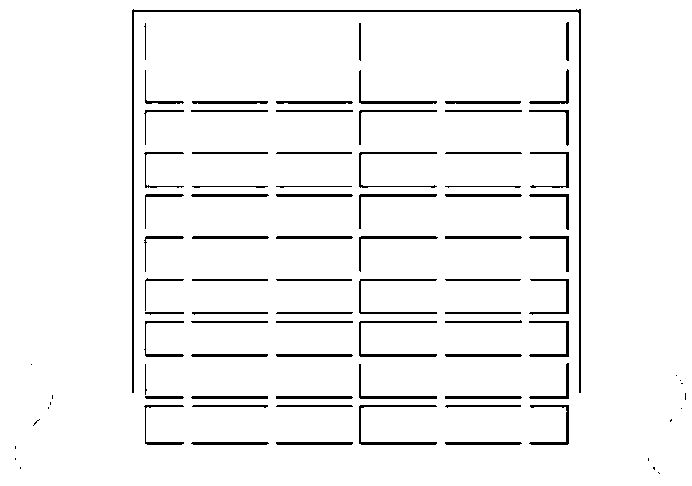

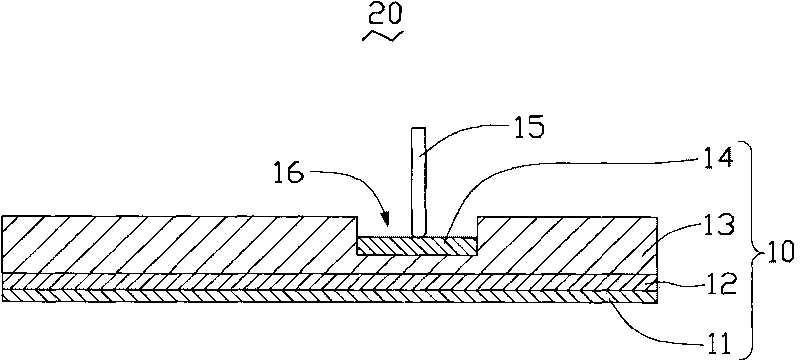

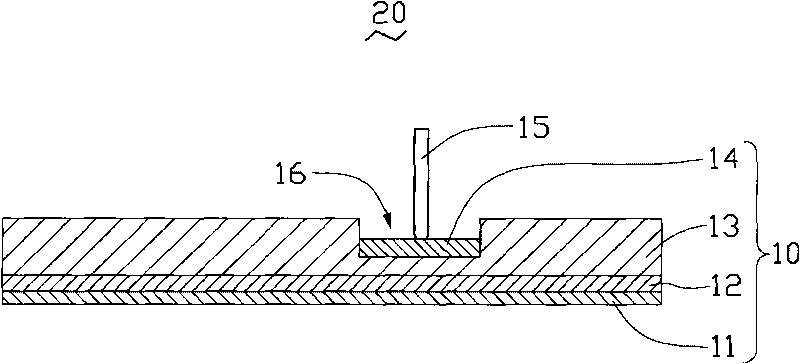

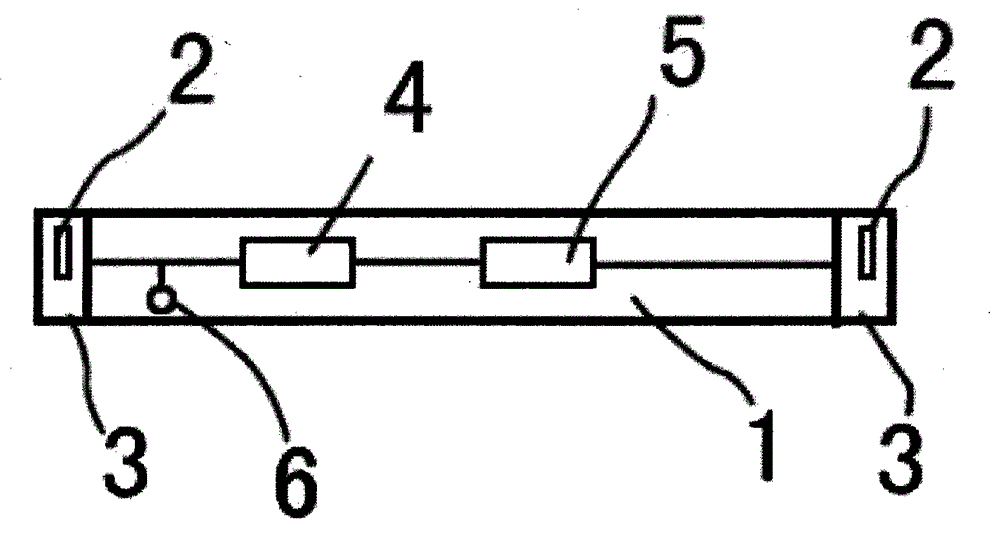

Secondary Battery Having Interconnected Positive and Negative Electrode Tabs

ActiveUS20110143194A1Simple processImprove reliabilityFinal product manufactureCurrent conducting connectionsElectrical and Electronics engineeringElectrode

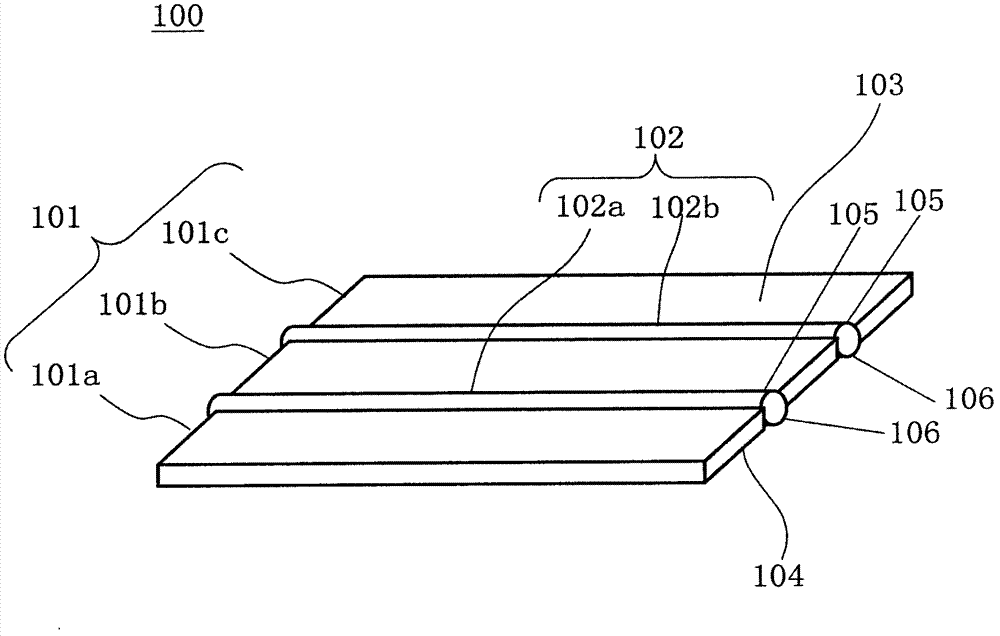

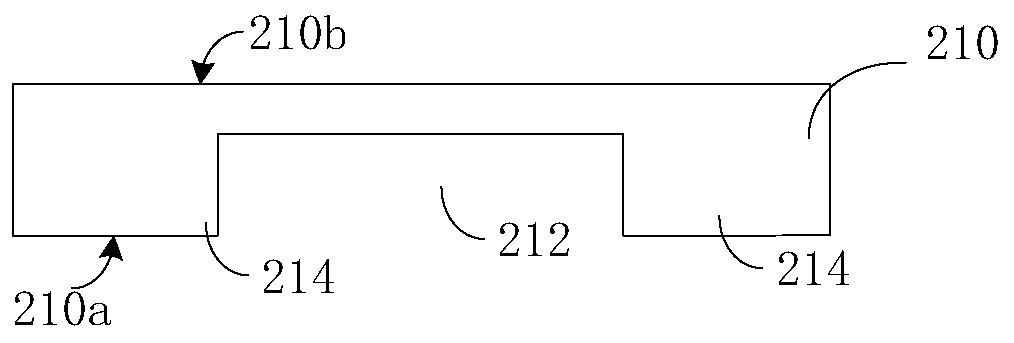

A secondary battery is capable of fastening a positive electrode tab and a negative electrode tab to each other without performing welding. The secondary battery comprises an electrode assembly including a positive electrode plate, a negative electrode plate, and a separator interposed between the positive electrode plate and the negative electrode plate, a positive electrode tab and a negative electrode tab coupled to the positive electrode plate and the negative electrode plate, respectively, a housing accommodating the electrode assembly and having one side open, a plate sealing up the open part of the housing, a fastening unit formed so as to protrude from the plate in a non-penetrating structure, and a first tab terminal inserted into the fastening unit via the positive electrode tab so as to electrically couple the positive electrode tab and the plate to each other.

Owner:SAMSUNG SDI CO LTD

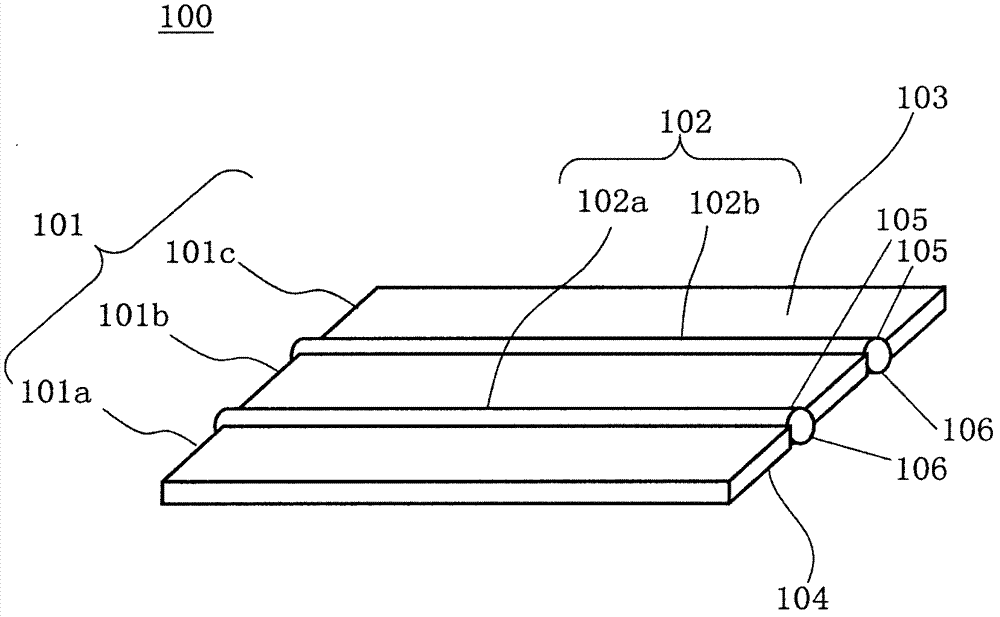

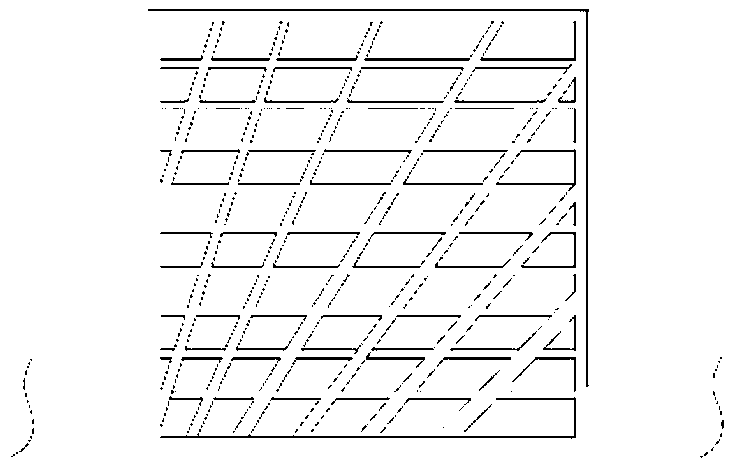

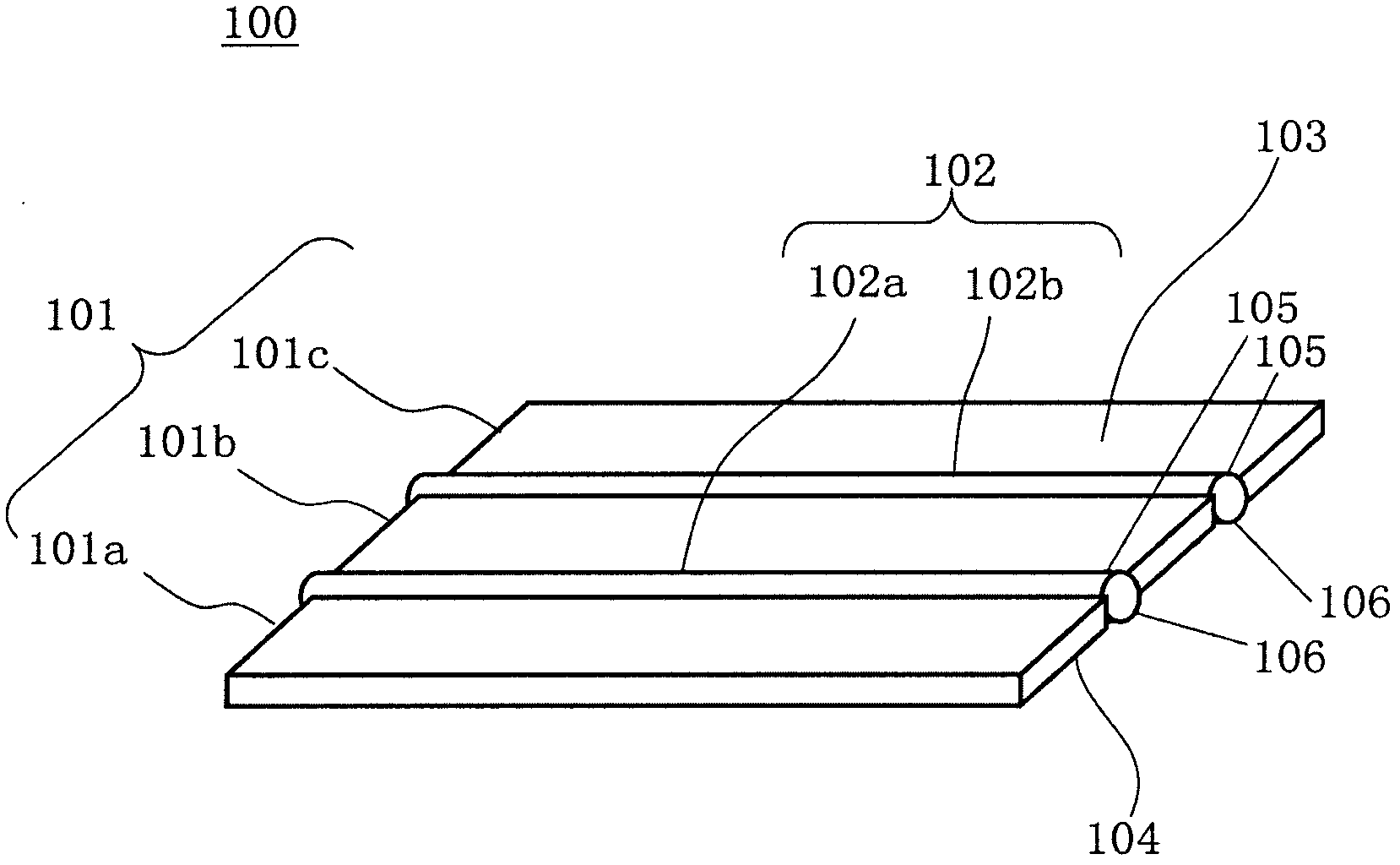

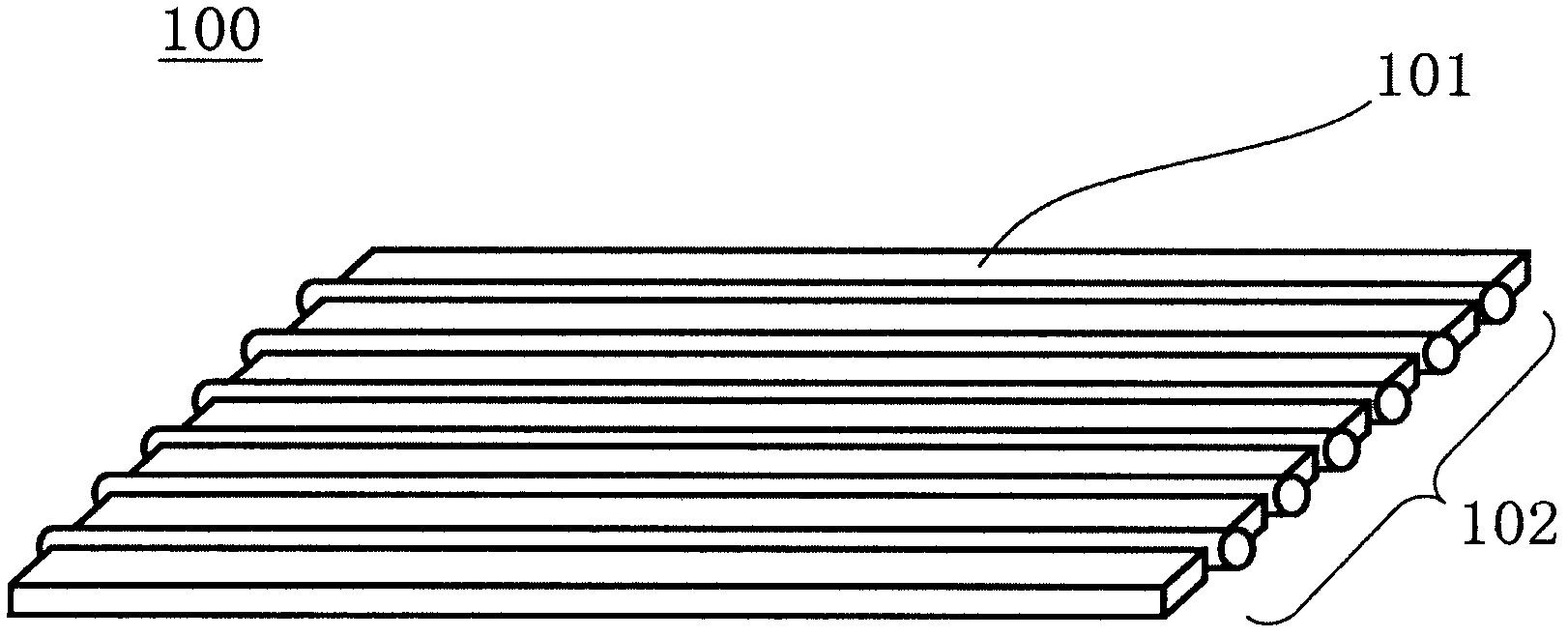

Machine for manufacturing electrode tape

ActiveCN102786882AFunctionalDisadvantages of Avoiding DestructionFilm/foil adhesivesSemiconductor/solid-state device manufacturingMechanical engineeringAdhesive materials

A machine for manufacturing an electrode tape includes a means for adhering an adhesive material to a sidewall of a conductive structure but not covering a first contact point and a second contact point of the conductive structure, and a means for curing the adhesive material into a film including a first adhesive surface on which the first contact point is exposed and a second adhesive surface on which the second contact point is exposed, wherein the first adhesive surface and the second adhesive surface face outwardly to each other.

Owner:NEO SOLAR POWER CORP

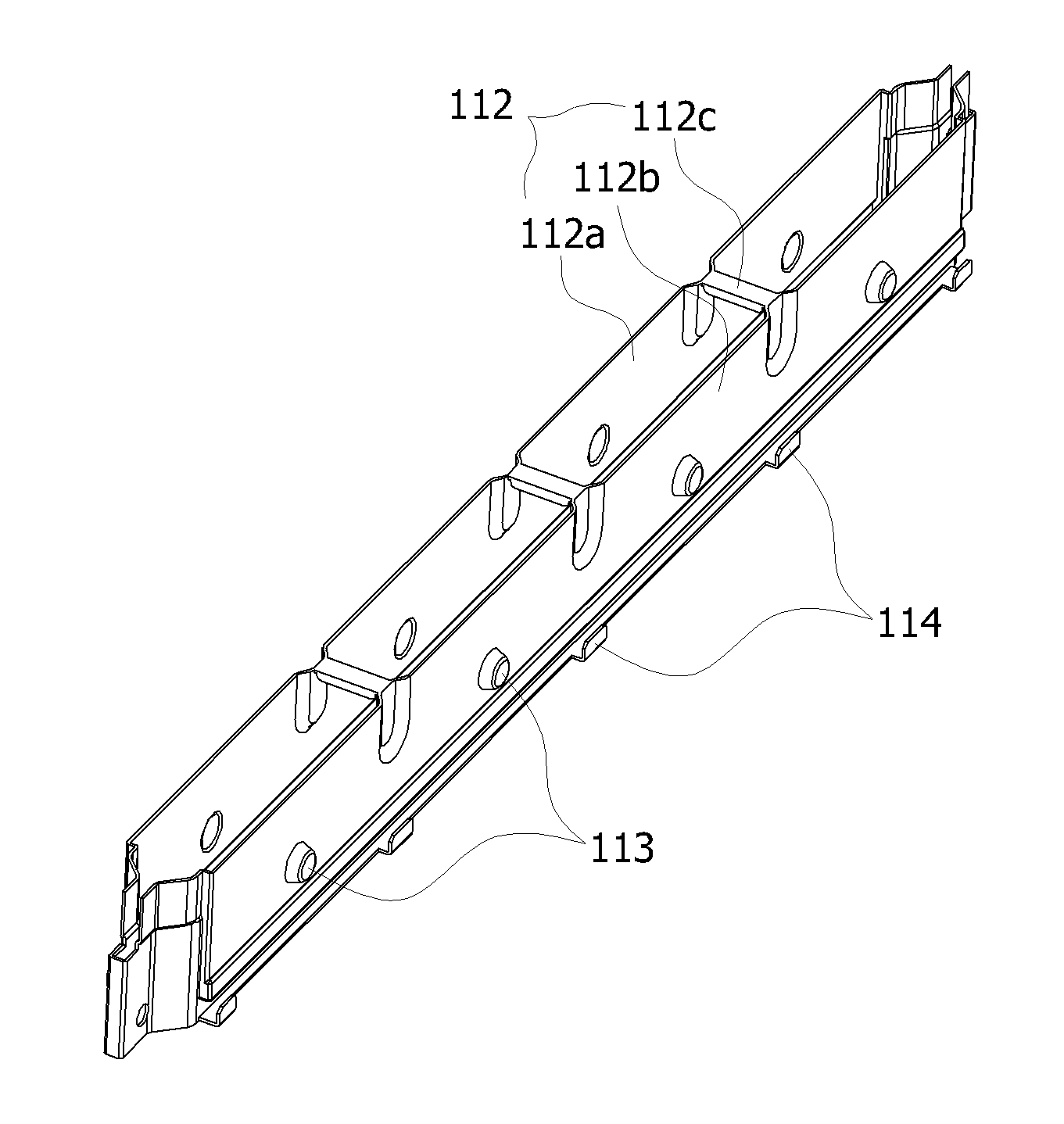

Gas burner

InactiveUS20120225393A1Reduce in quantityReduce manufacturing costFluid heatersGaseous fuel burnerMechanical engineeringGas burner

The present invention relates to a gas burner in which a burner body and a side plate are assembled together without a welding process, to thereby simplify manufacturing procedures and reduce manufacturing costs. To accomplish this, the gas burner of the present invention includes a plurality of burner units (110), each of which has a burner body (111) with a main flame being formed at the top thereof, a side plate (112) which forms auxiliary flame holes (116) in the spaces between both side surfaces of the burner body (111) and the side plate (112), and a plurality of supports (113, 114) protruding from the side plate (112). Both ends of each of the burner units (110) are supported by first and second brackets (200a, 200b), respectively. The supports (113, 114) formed at the side plate (112) of the burner unit are brought into contact with and are supported by supports (123, 124) formed at a side plate (122) of an adjacent burner unit (120).

Owner:KYUNGDONG NAVIEN

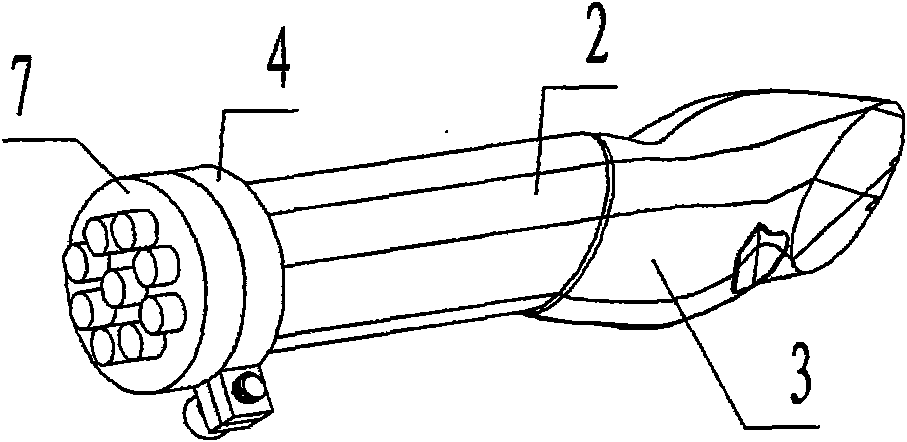

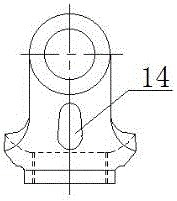

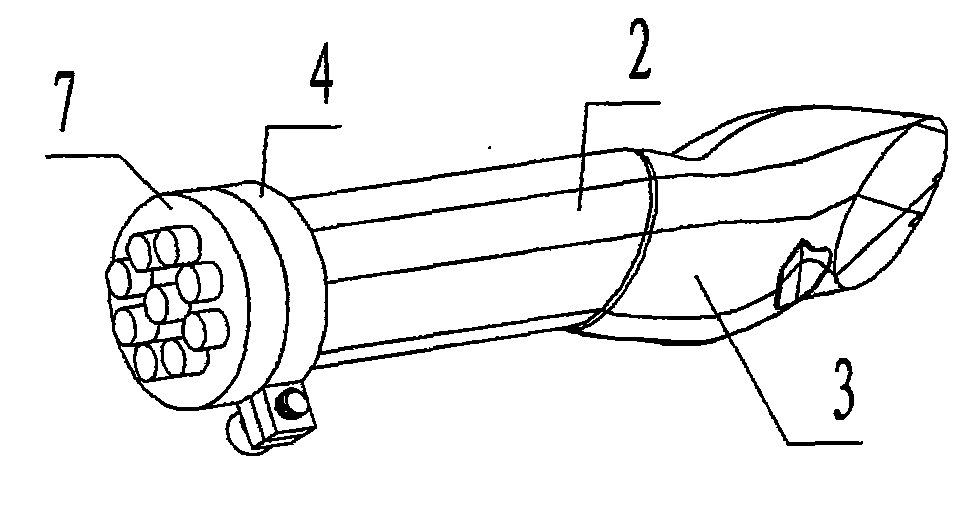

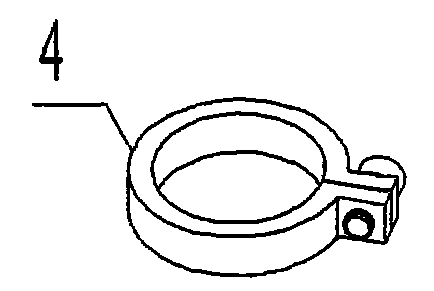

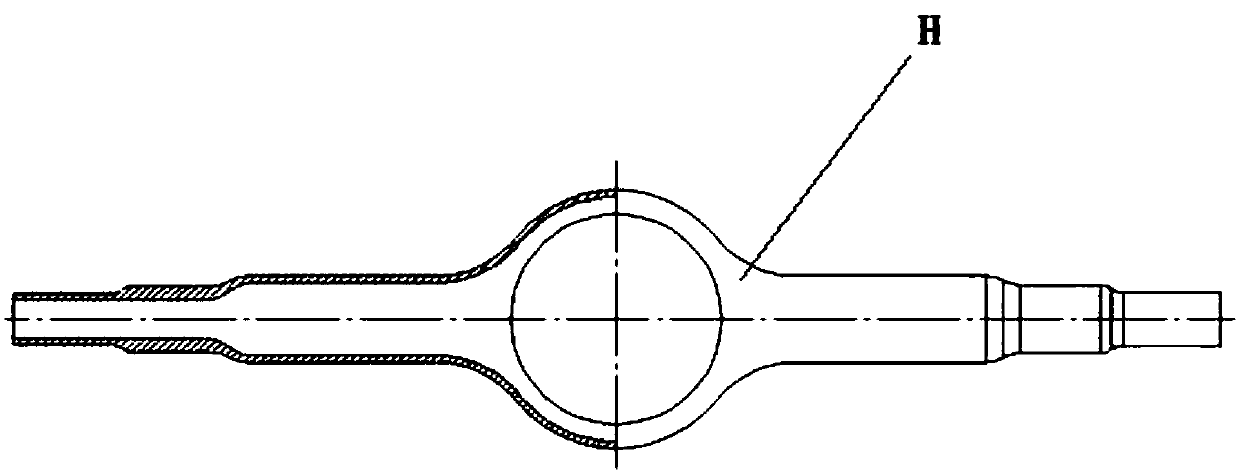

Combined knockout core structural investment pattern die bundling core

InactiveCN101564757AElimination of welding processConsistent sizeFoundry mouldsFoundry coresBatch productionEngineering

The invention discloses a combined knockout core structural investment pattern die bundling core, comprising a positioning mandrel, a drawing flap, a mould flap, a cramping device and a terminal base. The core is divided into nine flaps whose contact sides are parallel along the axial direction of the mould knockout core according to the mode of the Chinese character of ''Jing'', wherein the four cut surface rectangle flaps at the axial center are positioning mandrel, three cut surface flaps are drawing flaps and two cut surface flaps are mould flaps. The bundling solid core combined by nine flaps participates the investment pattern forming by inserting into the die, and draws out the positioning mandrel, the drawing flap and mould flap in turn during knockout. The combined knockout core structural investment pattern die bundling core avoids the welding procedure for the special form products in batch production by drawing the core in sequence, thus achieving the consistent dimension, high efficiency and low cost.

Owner:宁波双海机械制造有限公司

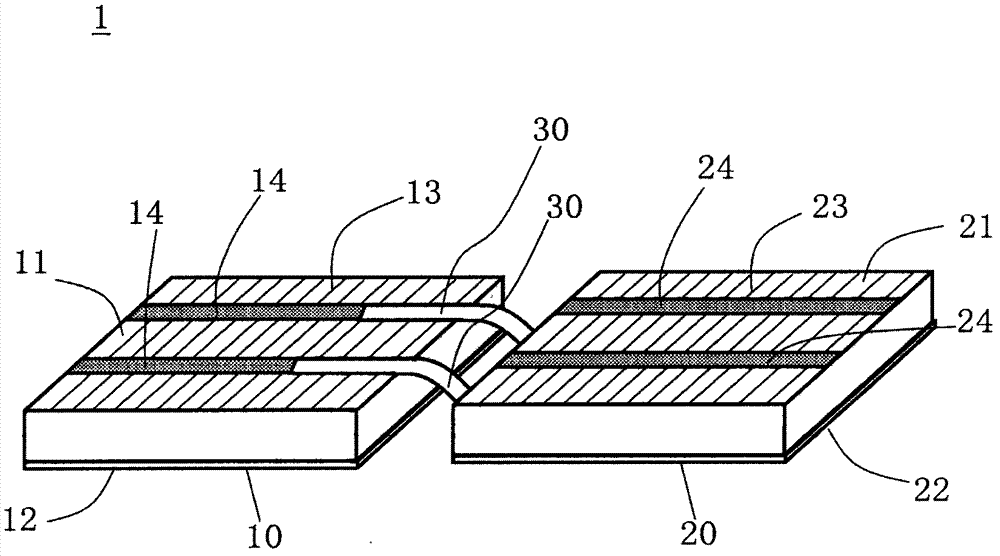

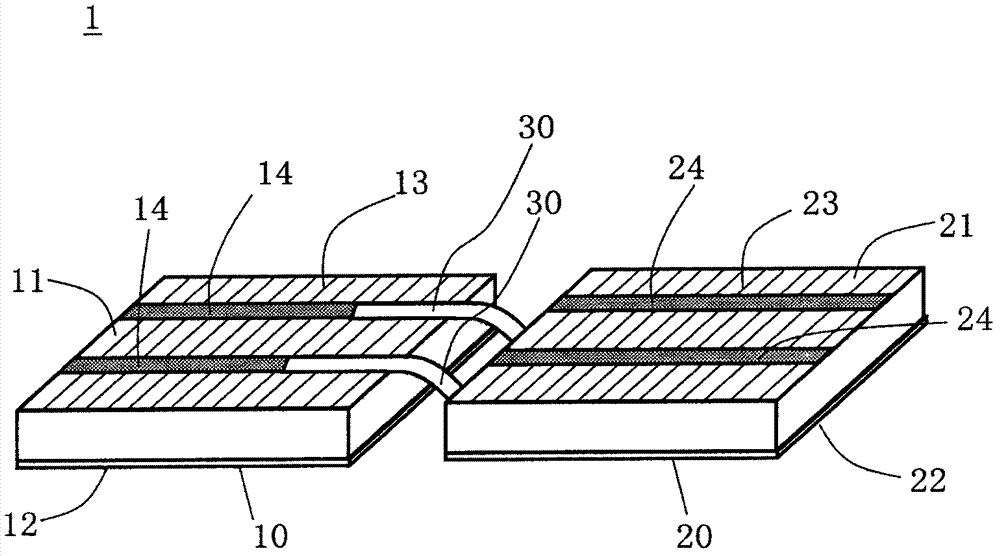

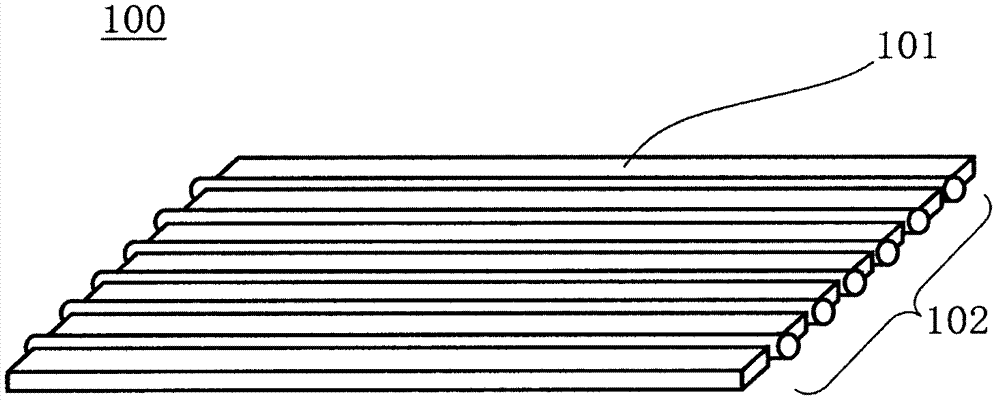

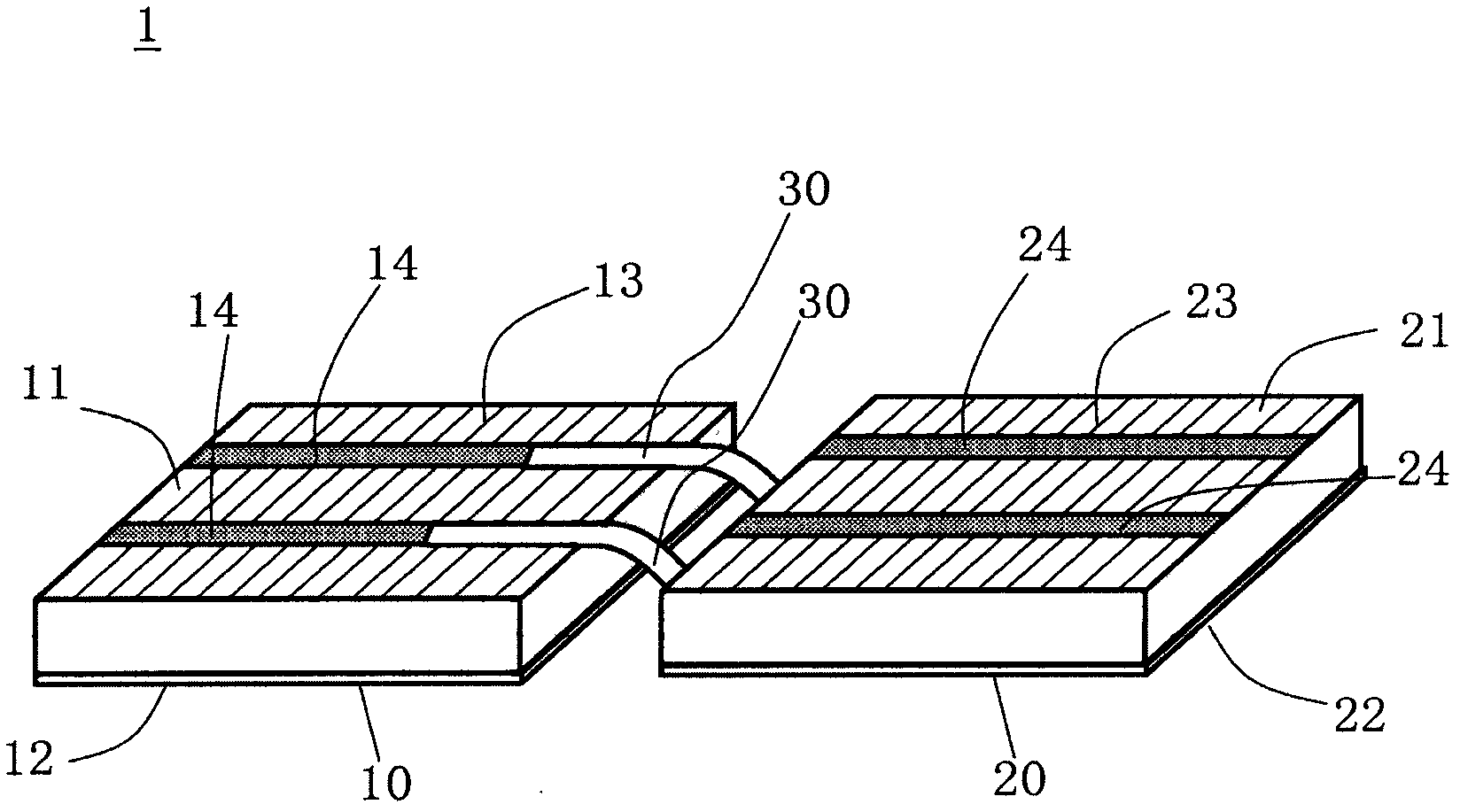

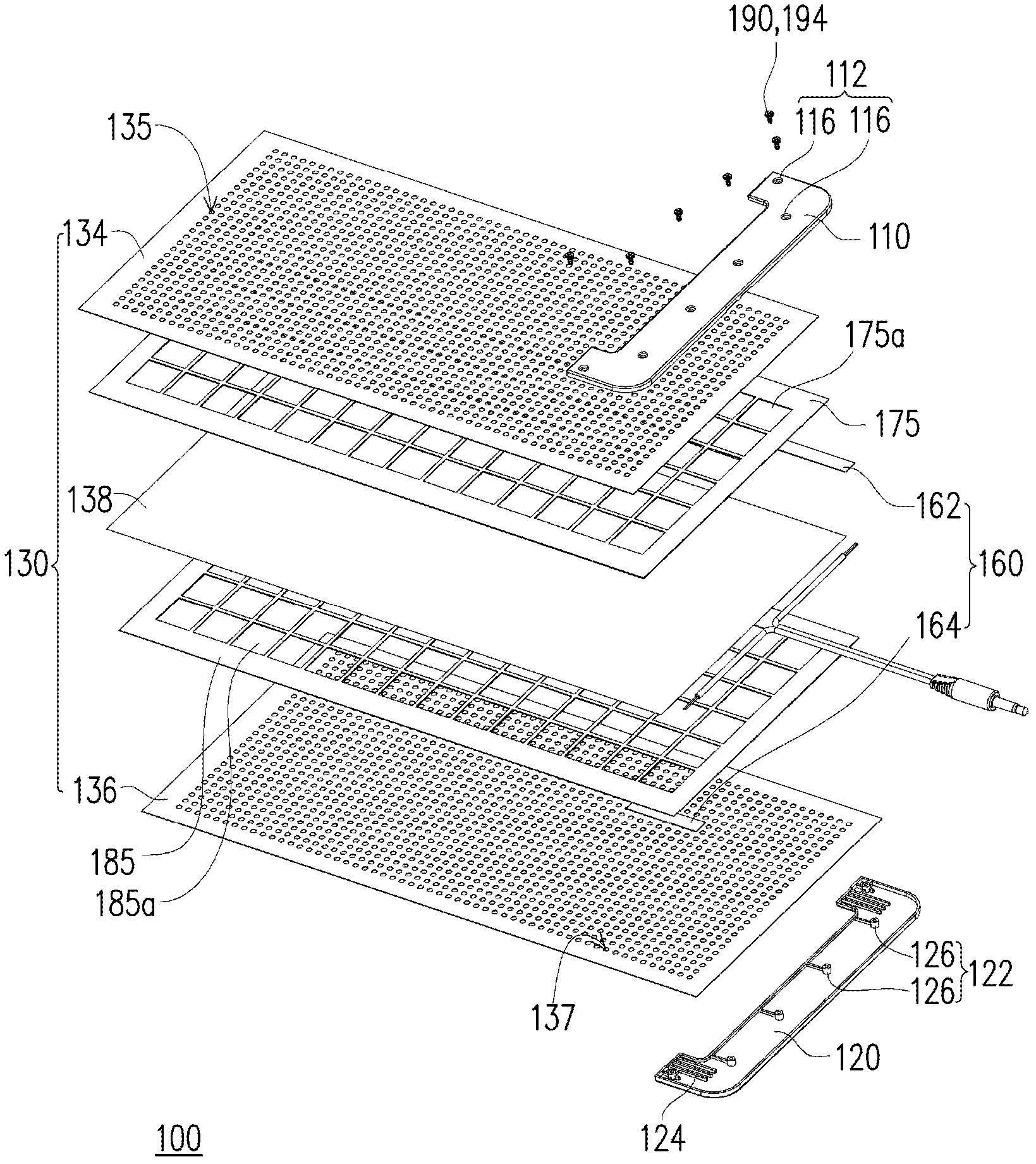

Electrode tape, solar cell module and methods for manufacturing the same

InactiveCN102786883AFunctionalDisadvantages of Avoiding DestructionSolid-state devicesElectrically conductive adhesive connectionsEngineeringSolar cell

An electrode tape and a method for manufacturing the same are disclosed. The electrode tape includes an adhesive film and a conductive structure. The adhesive film includes a first adhesive surface and a second adhesive surface which faces an opposite direction to the first adhesive surface. The conductive structure is embedded in the adhesive film with a first contact point exposed on the first adhesive surface and a second contact point exposed on the second adhesive surface. The cell module comprises the first solar cell and the second solar cell, which can be adhered to each other by using the electrode tape.

Owner:NEO SOLAR POWER CORP

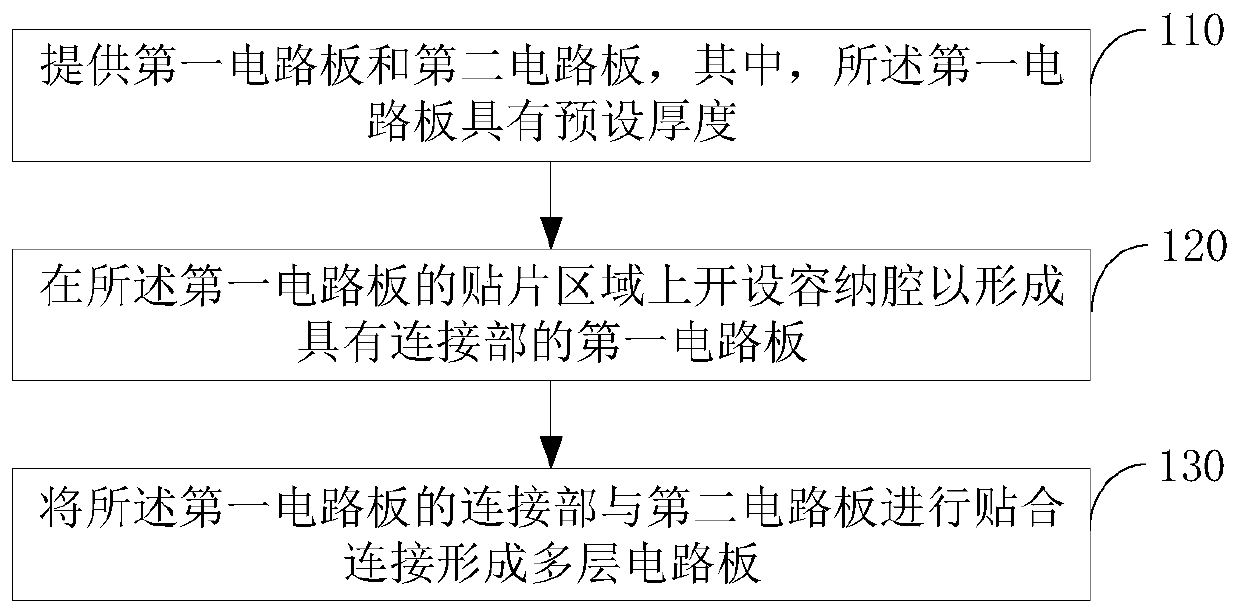

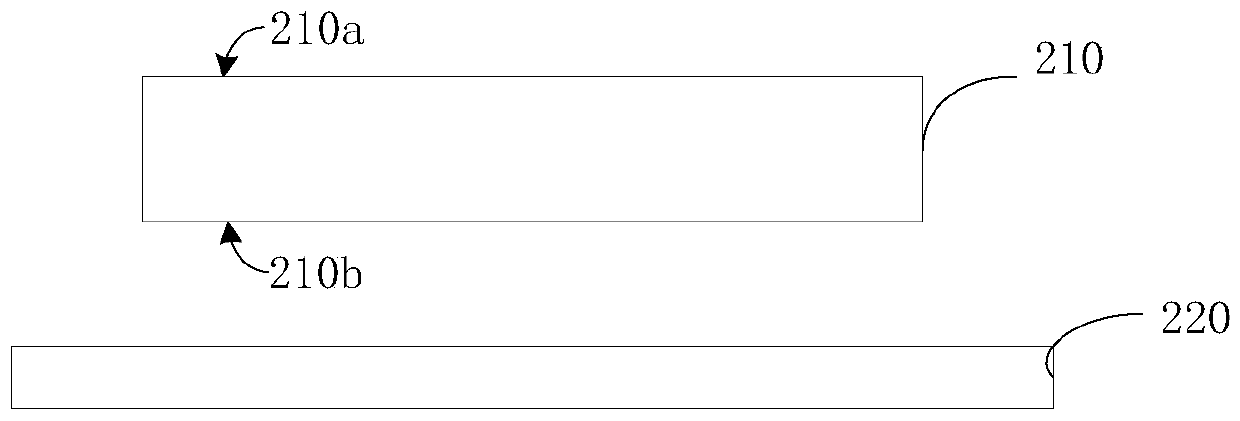

Manufacturing method of multilayer circuit board, multilayer circuit board and electronic equipment

InactiveCN110621122ASimple processing technologyReduce processing costsPrinted circuits structural associationsMultilayer circuit manufactureEngineeringWelding process

The embodiments of the invention provide a manufacturing method of a multilayer circuit board, a multilayer circuit board and electronic equipment. The manufacturing method of the multilayer circuit board comprises the following steps that: a first circuit board and a second circuit board are provided, wherein the first circuit board has a preset thickness; an accommodating cavity is formed in thechip mounting area of the first circuit board, so that a first circuit board with a connecting part can be formed, the depth of the accommodating cavity is smaller than the thickness of the first circuit board; and the connecting part of the first circuit board and the second circuit board are stacked so as to form the multilayer circuit board, the opening direction of the accommodating cavity faces the second circuit board, and the accommodating cavity is used for accommodating components which are installed on the second circuit board and face the first circuit board. With the manufacturingmethod of the multilayer circuit board, the multilayer circuit board and the electronic equipment of the invention adopted, a chip mounting process and a welding process can be simplified, the welding reject ratio of products is reduced, cost is reduced, and production efficiency is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Welding-free storage battery and production method thereof

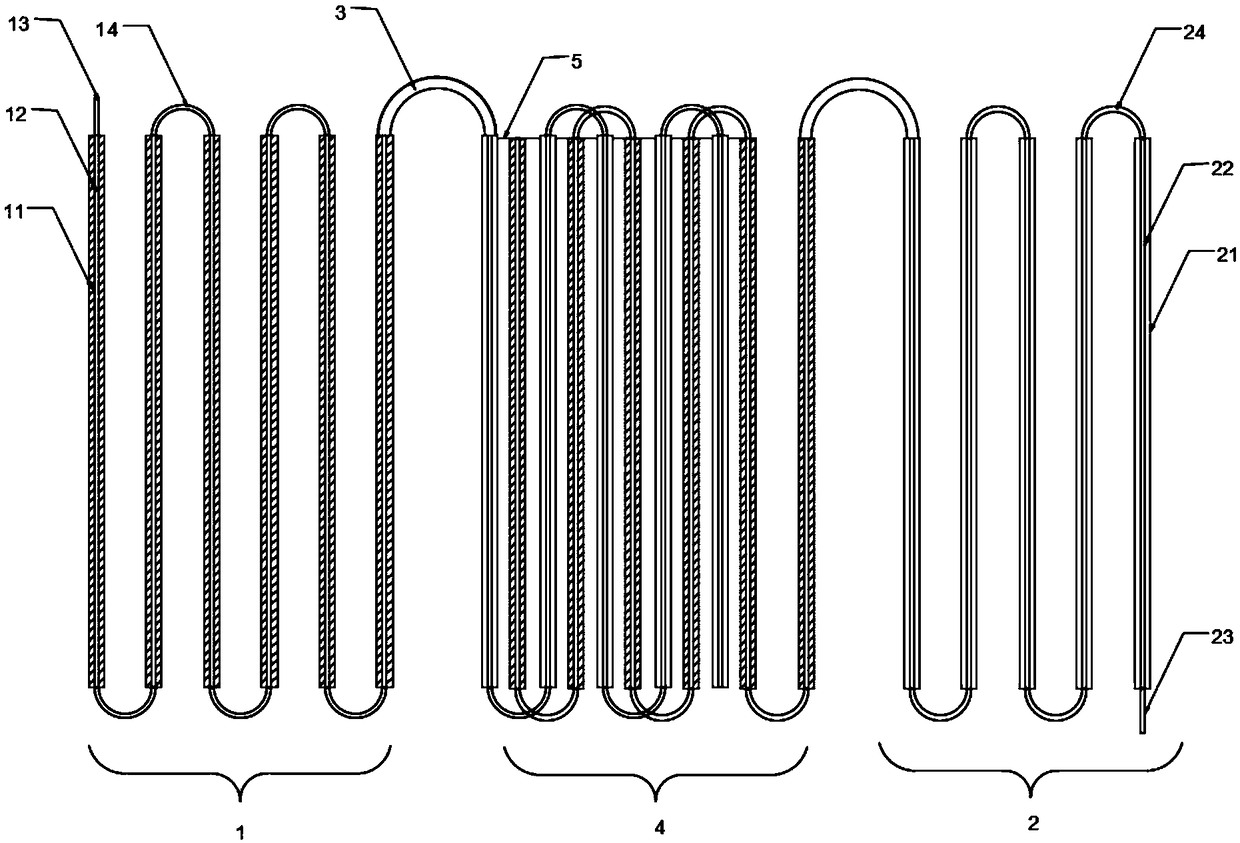

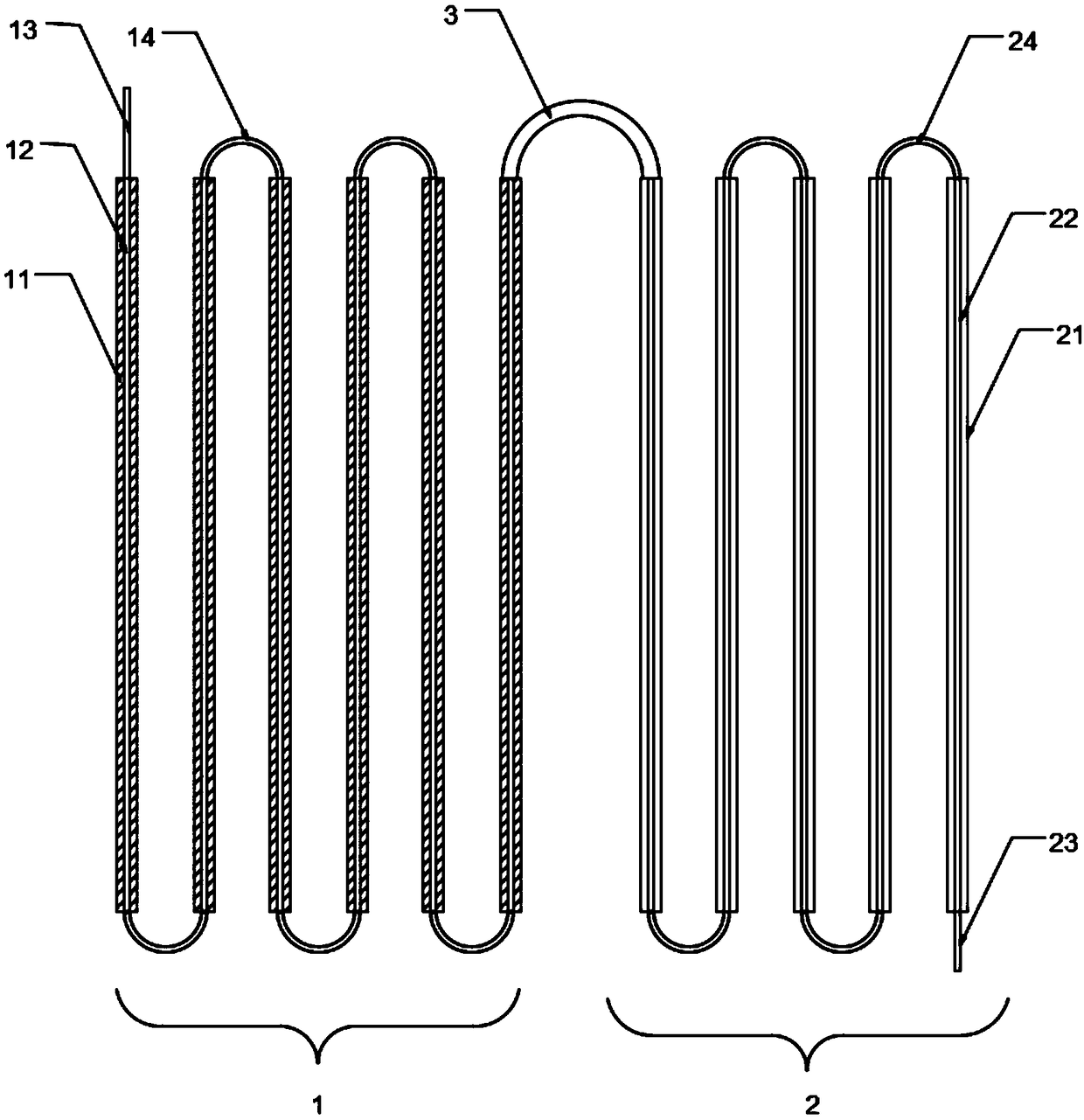

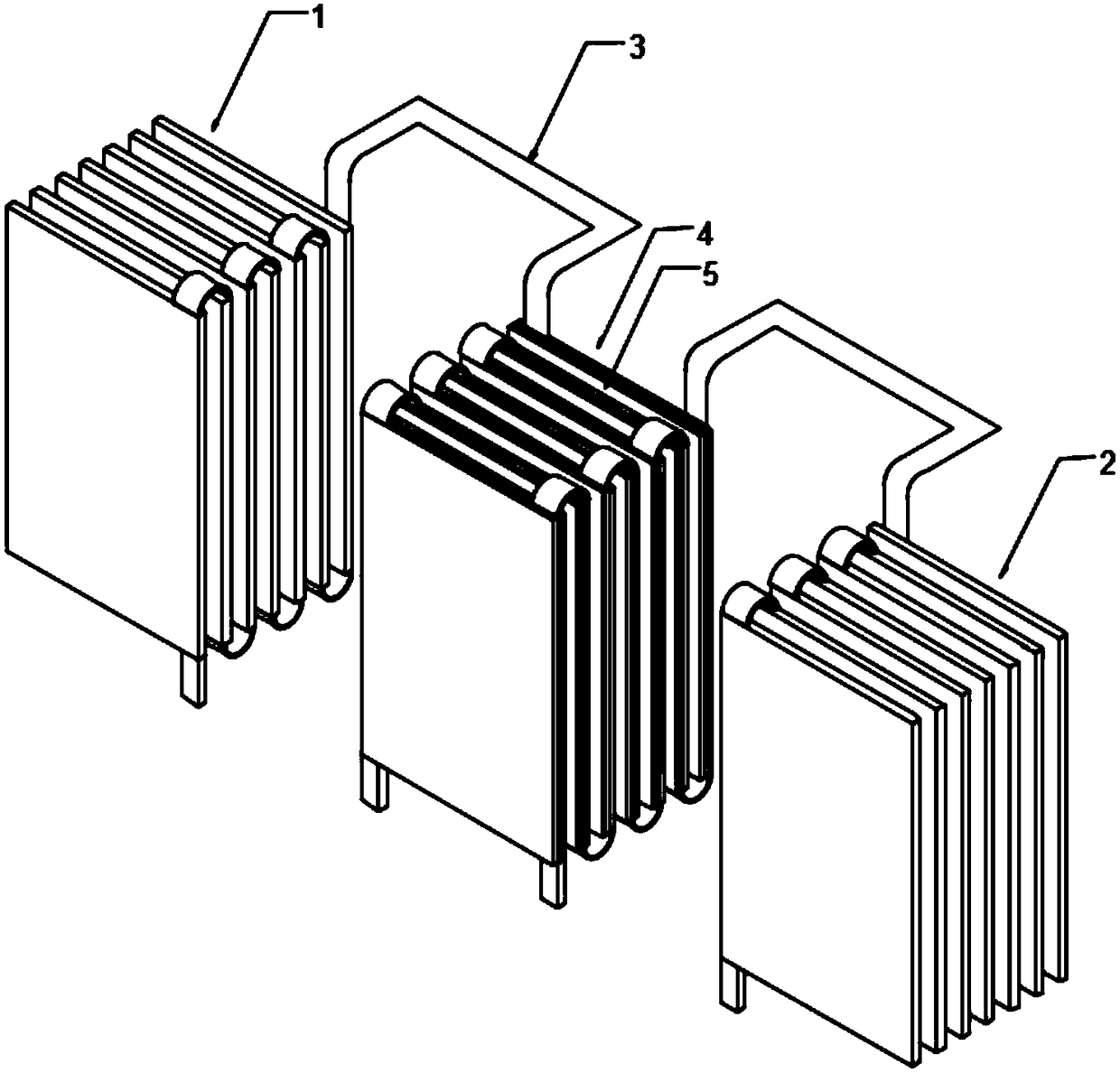

PendingCN108666636AReduce the amount of lead usedQuality improvementFinal product manufactureLead-acid accumulator electrodesContinuous designEngineering

The invention relates to the technical field of chemical power supply materials and in particular relates to a welding-free storage battery and a production method thereof. A continuous type welding-free lead storage battery pole group comprises continuous type positive electrode plates, continuous type negative electrode plates, a single-body-spanning connection sheet, a continuous type bipolar pole plate and a separation plate, wherein the continuous type bipolar pole plate is composed of the continuous type positive electrode plates, the continuous type negative electrode plates and the separation plate, which are inserted and matched. According to the welding-free storage battery provided by the invention, an integrated continuous design is carried out on the lead storage battery polegroup and a welding procedure of a plurality of pieces of the positive electrode plates or negative electrode plates in a pole plate group during a storage battery production process is eliminated; aserial and parallel connection welding procedure of bridge-spanning welding, wall-penetrating welding and the like of a plurality of single bodies of the storage battery is also eliminated. Therefore,the use amount of lead of the storage battery is reduced and sheet falling and missing welding phenomena do not happen between the pole plate group of the storage battery and the single bodies; the product quality and reliability of the storage battery are effectively improved.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

A continuous solder-free lead-acid battery electrode group and a manufacturing method thereof

PendingCN109004291AReduce the amount of lead usedQuality improvementFinal product manufactureCell component detailsBiochemical engineeringMonomer

The invention relates to the technical field of chemical power supply materials, in particular to a continuous solderless lead-acid battery electrode group and a manufacturing method thereof. The continuous solder-free lead-acid battery electrode group comprises a continuous positive electrode plate, a continuous negative electrode plate, a cross-unit connecting piece, a continuous bipolar electrode plate and a separator, wherein the continuous bipolar electrode plate is composed of a continuous positive electrode plate, a continuous negative electrode plate and a separator which are insertedand matched. A lead storage battery electrode group is integrally and continuously design, and that welding procedure of a plurality of positive plate or negative plates in the electrode plate group in the production process of the storage battery is eliminated, and the series and parallel welding procedures such as cross-bridge welding and through-wall welding between a plurality of monomers of the storage battery are also eliminated. This not only reduces the lead consumption of the battery, but also does not appear the phenomenon of chips falling off and missing welding between the electrode plate group and the monomer of the battery, which effectively improves the product quality and reliability of the battery. In addition, the electrode group of the invention has high manufacturing process efficiency and is convenient for production and processing.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Method for welding coiler on large container

ActiveCN1899743ANice appearanceQuality improvementArc welding apparatusContinuous operationEngineering

The process of welding coil onto large container includes the following steps: 1. machining plate into semi-circular pipe; 2. machining the semi-circular pipe into bend pipe for the container cylinder in the required diameter; 3. winding the bend pipe onto the surface of the container cylinder; and 4. welding the coil onto the container. The present invention has continuous operation, short production time, elimination of circumferencial weld seal, less leakage possibility and good appearance of the coil.

Owner:上海贤达美尔森过程设备有限公司

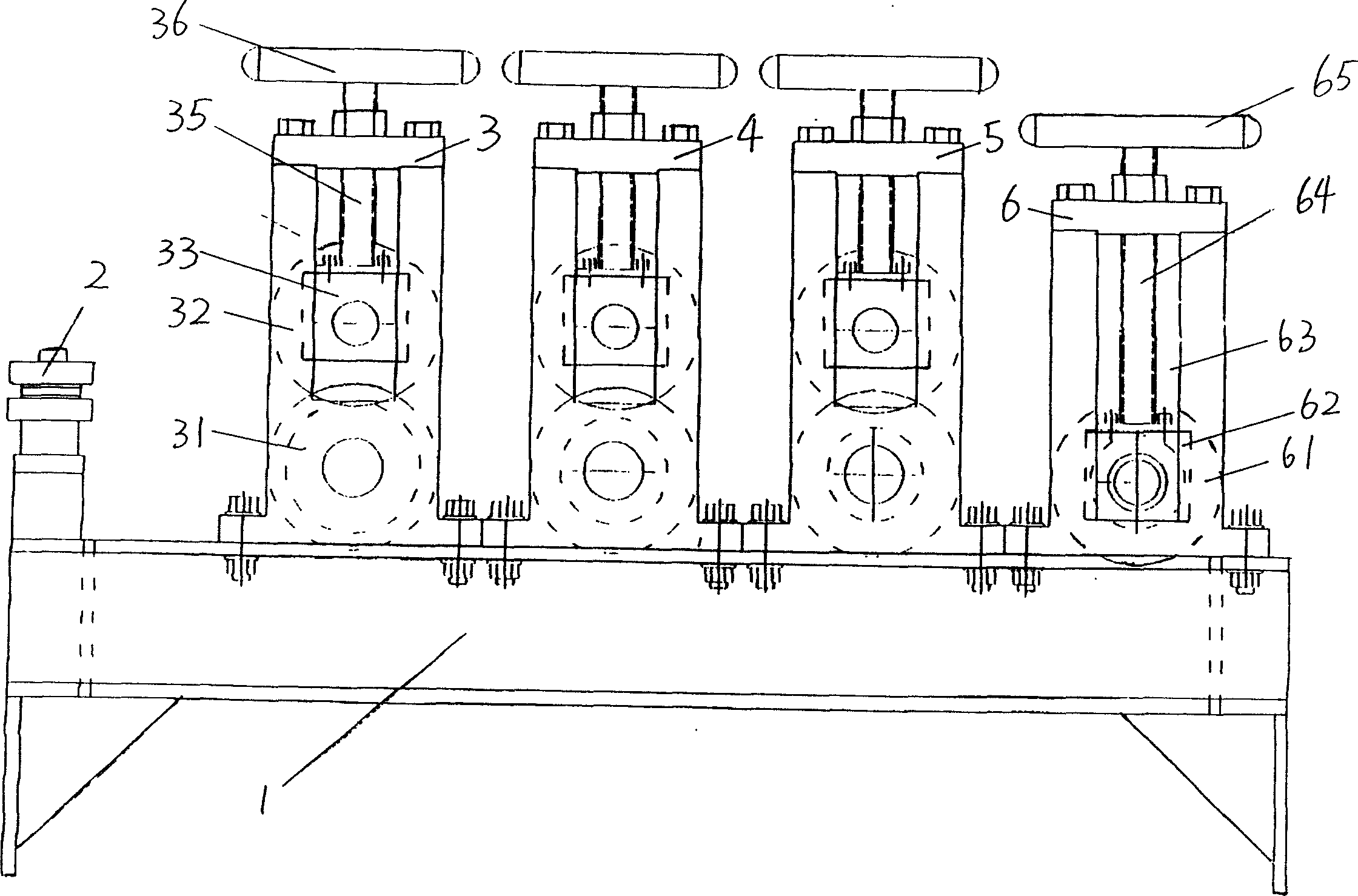

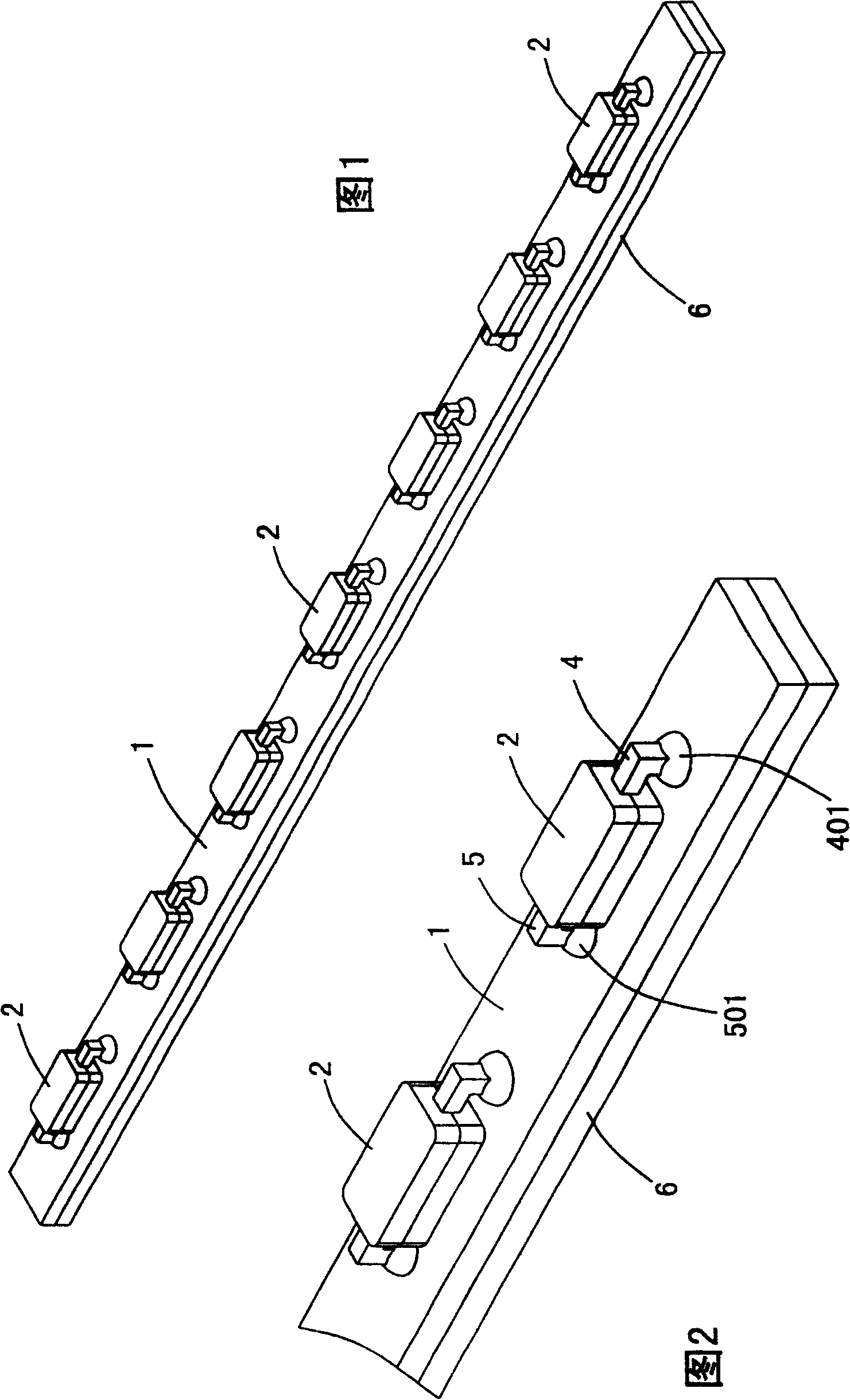

Method of manufacturing electrolyzer unit, and method and system for welding electrolyzer unit and electrolyzer unit rib

InactiveUS7175745B2Maintain qualityReduce lossesCellsWelding/soldering/cutting articlesEngineeringFlange

The invention has an object of facilitating the detection of defective welds and improving the efficiency of manufacturing electrolyzer units. A a method of manufacturing an electrolyzer unit comprises a step of arranging a partition member on a front surface of a cathode pan and welding a top side and a left side of the cathode pan to the partition member to form a gas-liquid separation chamber, a step of performing a similar step on an anode pan, a step of arranging cathode ribs on a front surface of the cathode pan and clad plates on a back surface of the cathode pan at positions corresponding to the cathode ribs, welding them at the same time, putting a back surface of the anode pan over the back surface of the cathode pan and arranging anode ribs on a front surface of the anode pan at positions corresponding to the clad plates, a step of simultaneously performing on the anode pan a similar step of arranging anode ribs on a front surface of the anode pan at positions corresponding to the clad plates, and a step of inserting frame members into spaces formed between flange portions of the cathode pan and flange portions of the anode pan.

Owner:FUJITA WORKS +1

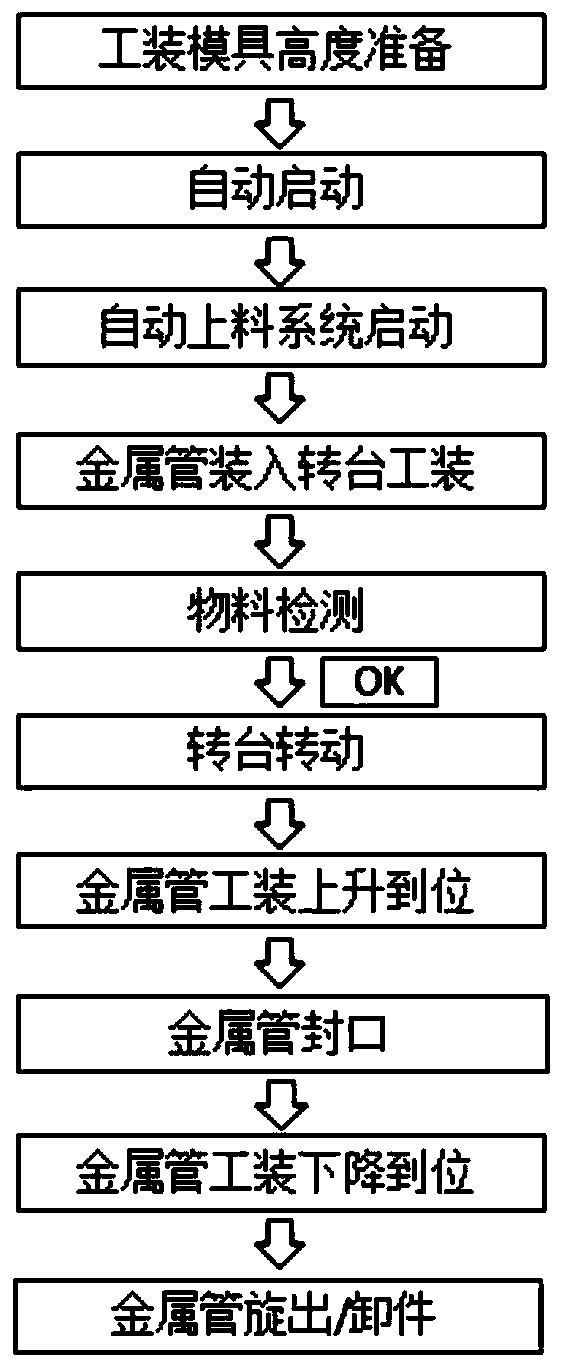

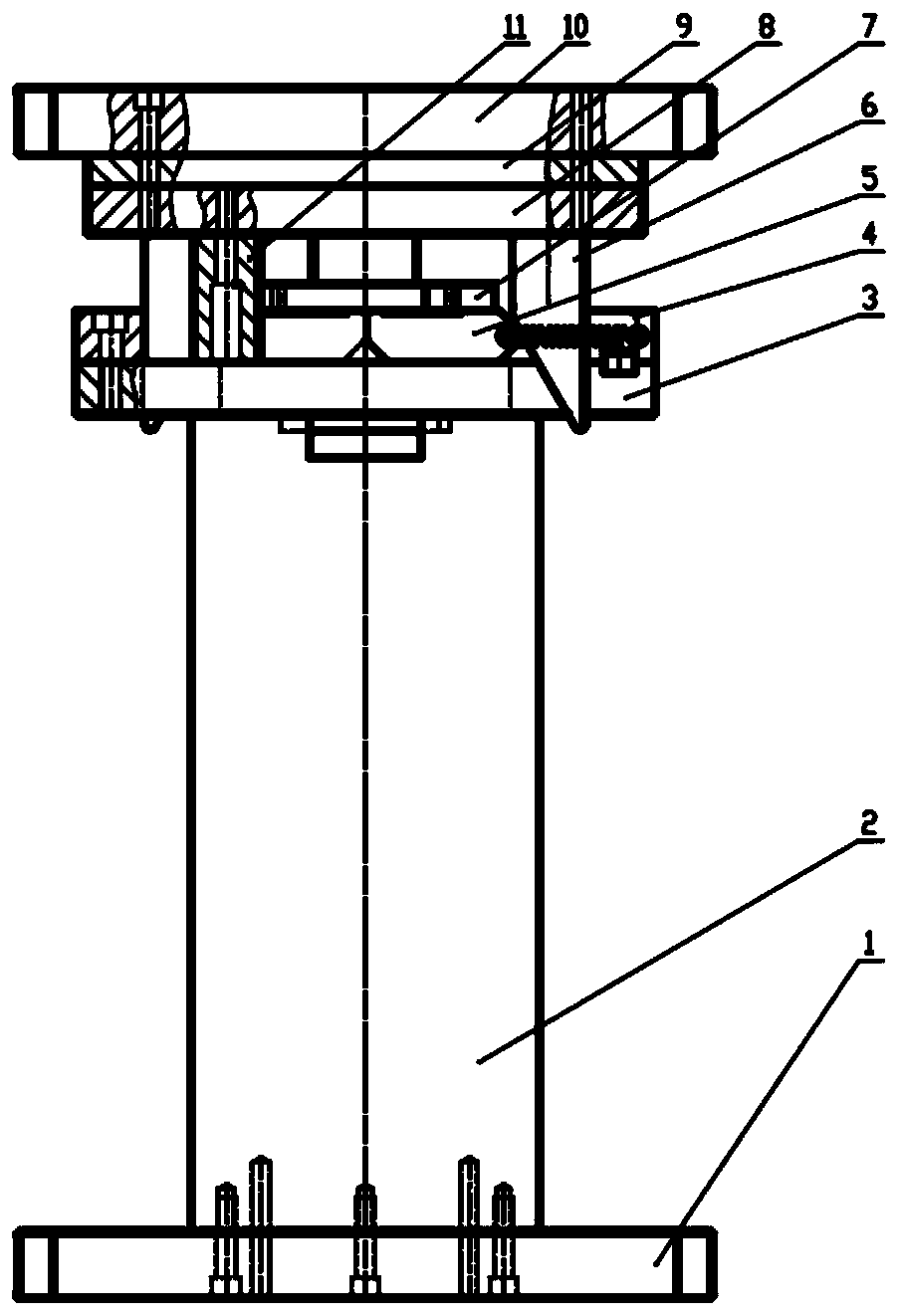

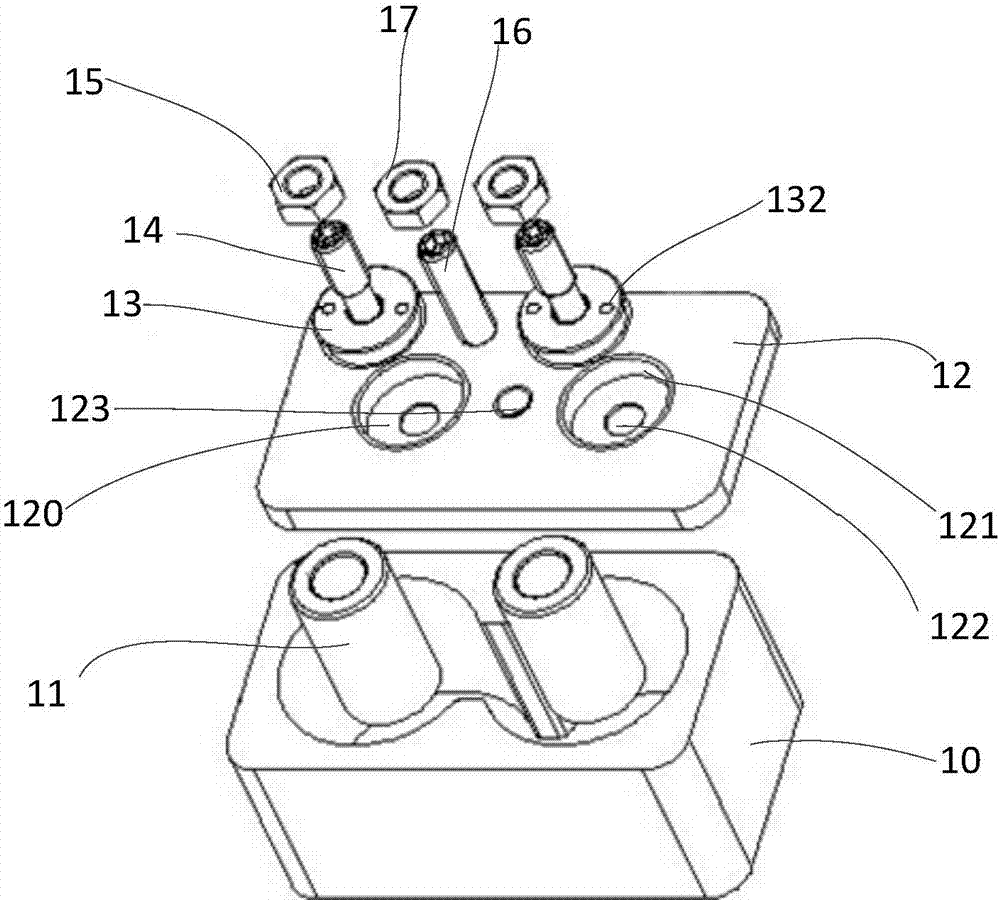

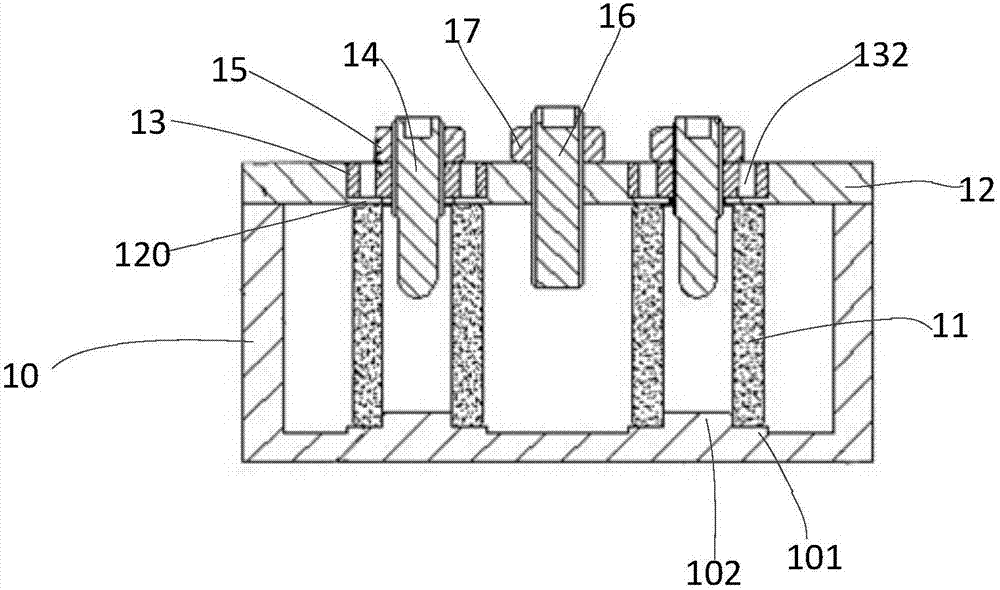

Metal pipe fitting port sealing device

InactiveCN111570631AAutomatic filling detection safetyAutomatic filling detection is convenientShaping toolsPipe fittingEngineering

One or more embodiments of the invention provide a metal pipe fitting port sealing device. The metal pipe fitting port sealing device is used in cooperation with an intelligent sealing machine and comprises an upper die and a lower die; the upper die comprises an upper die mounting plate, a guide column, a guide column mounting base, a supporting rod, a supporting rod mounting base, a pipe fittingpositioning tool and a positioning tool adjusting base. According to the automatic pipe fitting sealing device, manual operation is not needed in the whole process, automatic ordered work is carriedout according to a set program, the consistency and accuracy of metal pipe sealing are controlled, the control function of the device is diversified, expansibility is good, intelligent control is achieved, and automatic fiber filling detection becomes safer, more convenient and more reliable. Operators are reduced, stamping and welding procedures are eliminated, and the production process is moreeconomical and environment-friendly.

Owner:WUHU INST OF TECH

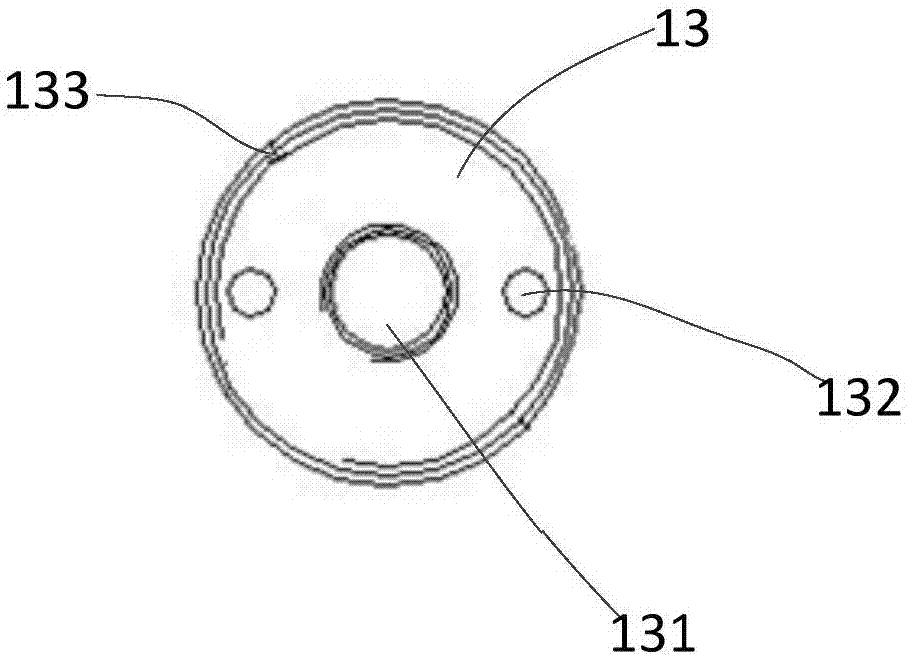

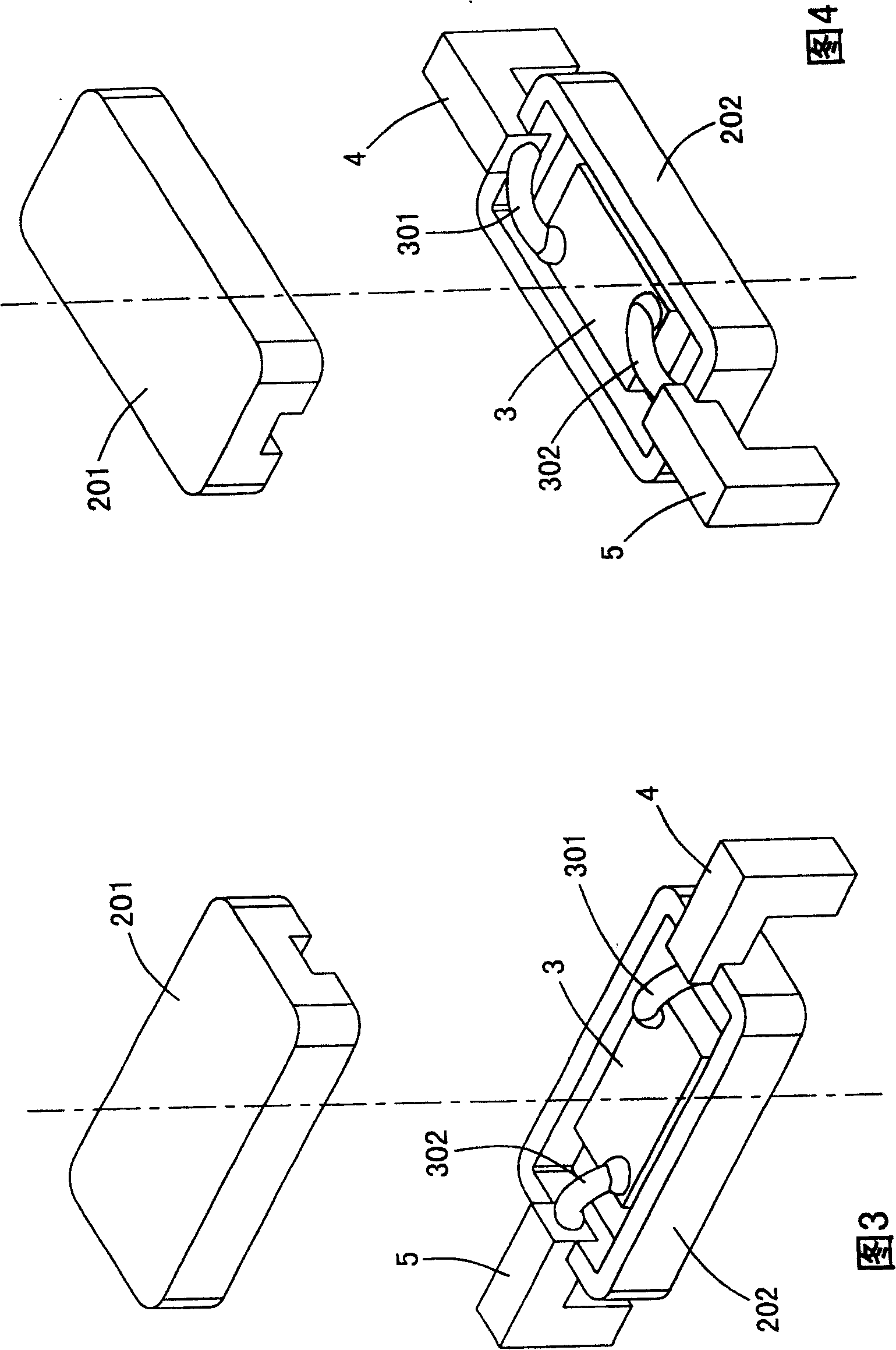

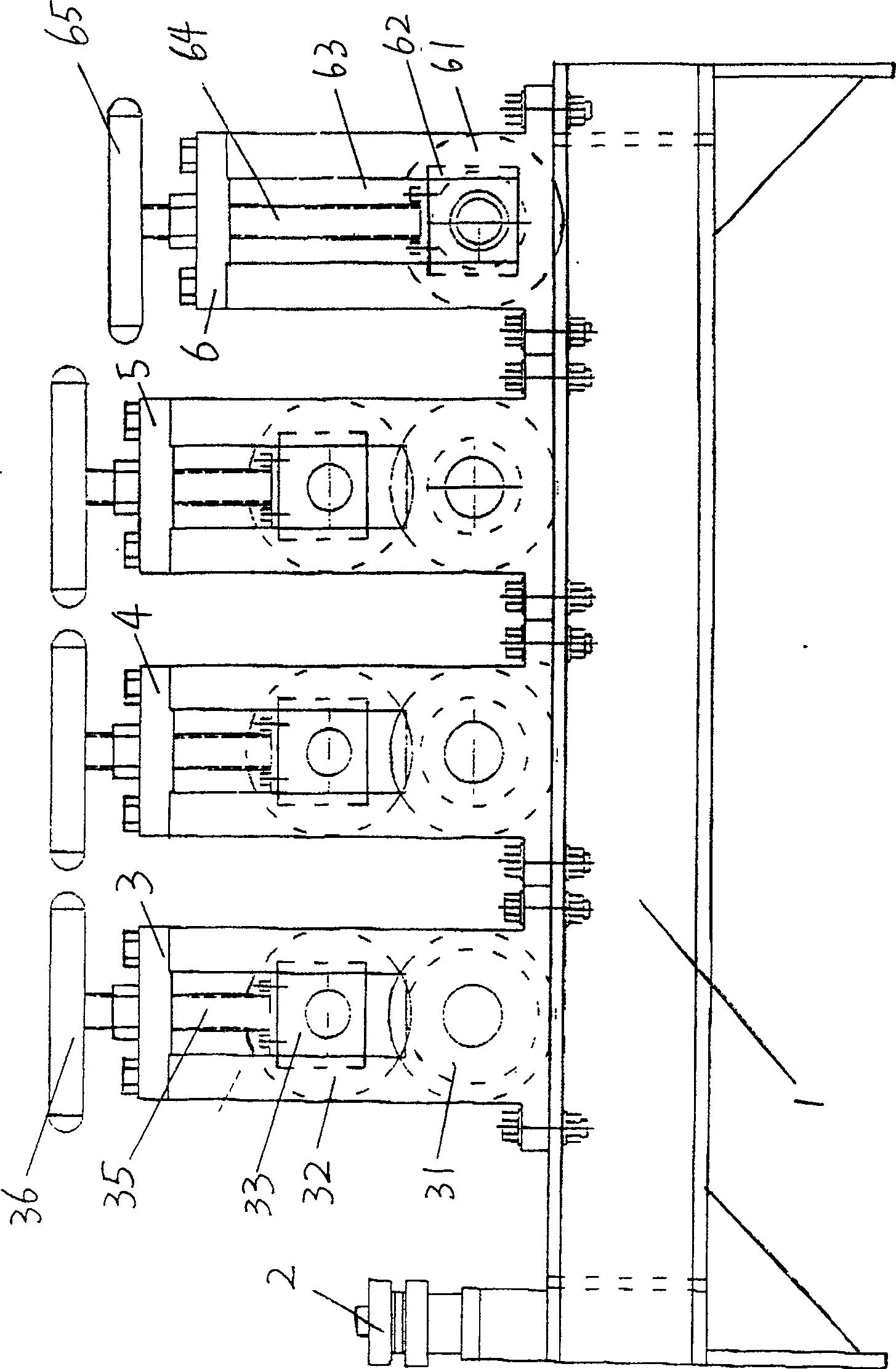

Dielectric resonator and assembly method thereof

The invention relates to a dielectric resonator and an assembly method thereof. The dielectric resonator includes a metal cavity, dielectric resonant posts located in the metal cavity and a metal cover plate mounted to an open end of the metal cavity. Mounting grooves are arranged in the top surface of the metal cover plate and corresponding to the dielectric resonant posts. A pressing piece is formed between the bottom of each mounting groove and the bottom surface of the metal cover plate. The pressing pieces and upper end faces of the dielectric resonant posts are in contact and first elastic deformations acting on the upper end faces of the dielectric resonant posts are generated therebetween. The mounting grooves are equipped with clamp nut posts. Second elastic deformations acting on the upper end faces of the dielectric resonant posts are generated between the clamp nut posts and the pressing pieces. The dielectric resonant posts are pressed and fixed into the metal cavity through the combined action of the first and second elastic deformations. According to the invention, good contact of the dielectric resonant posts with the metal cavity and the metal cover plate can be ensured without fixing the upper and lower end faces of the dielectric resonant posts by welding, the fixation is reliable, the assembly is simple and batch production is facilitated.

Owner:SHENZHEN GRENTECH RF COMM LTD

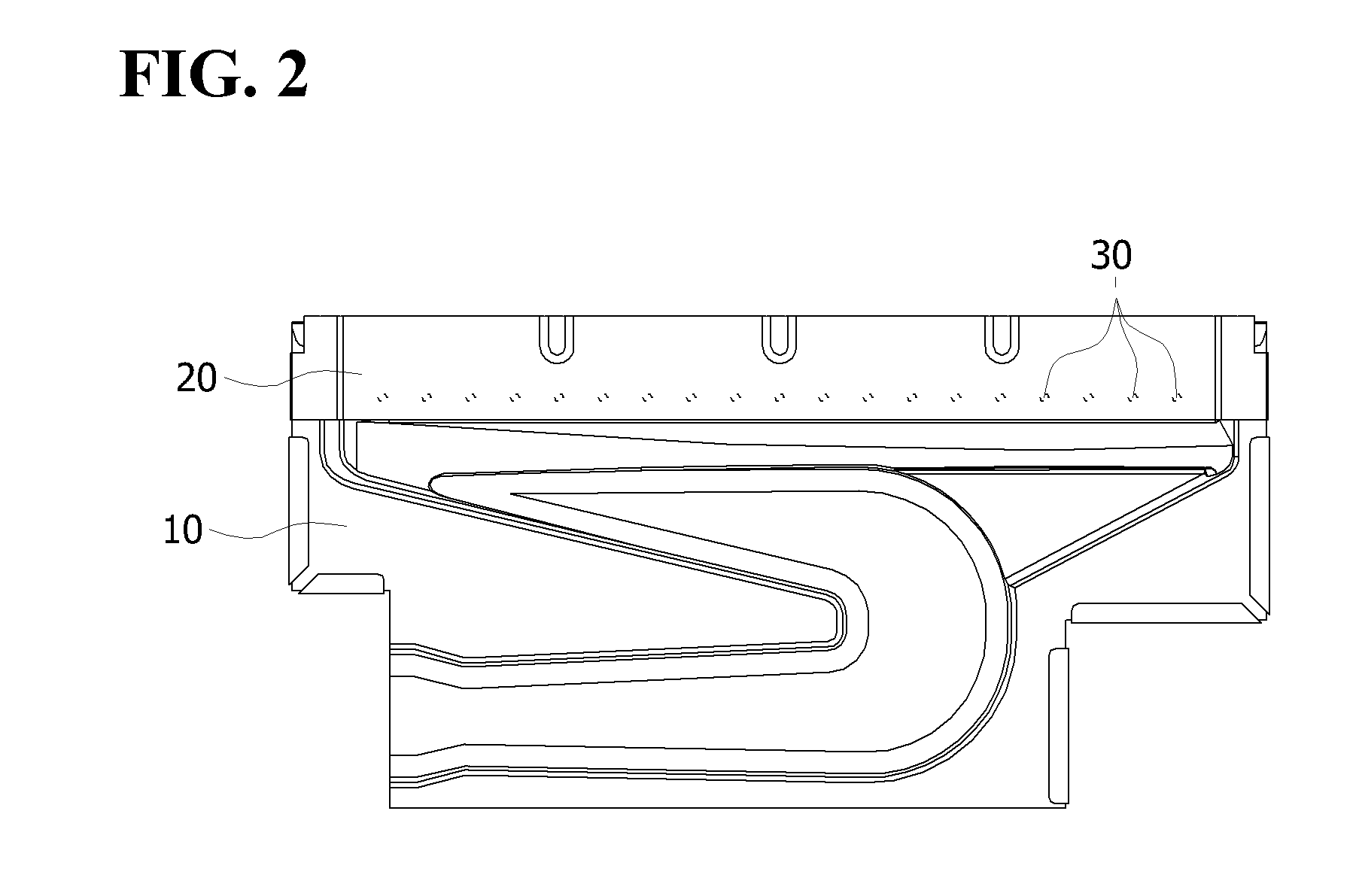

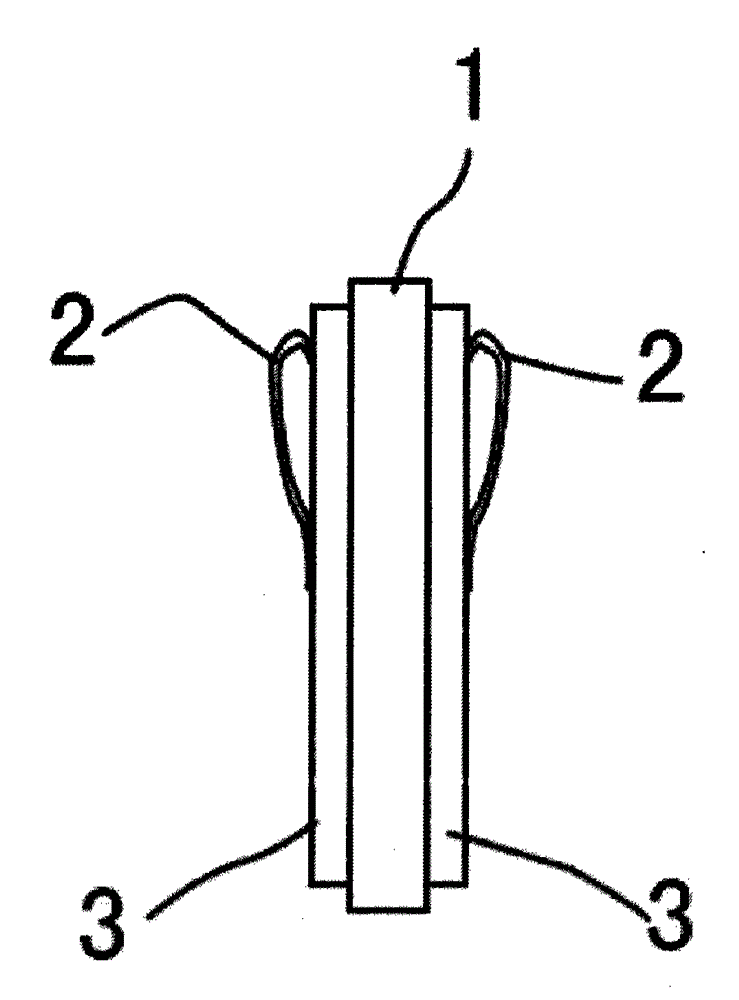

Soft package lithium battery with welding-free structure

ActiveCN105870510ACompact structureElimination of welding processFinal product manufactureElectrolyte accumulators manufactureLithium batteryElectrical and Electronics engineering

The invention provides a soft package lithium battery with a welding-free structure and belongs to the field of batteries. The soft package lithium battery comprises a plurality of cores which are sequentially connected through current collecting strips. The cores comprise lugs. A containing space is formed between every two adjacent cores. Each current collecting strip comprises a plurality of current collecting elements arranged at intervals, wherein the distribution direction of the current collecting elements is the length direction of the current collecting strip, and the extending direction of each current collecting element is perpendicular to the length direction of the current collecting strip. The current collecting elements are clamped into the containing spaces and connected with the lugs. The soft package lithium battery is compact in structure, the welding procedure in the bunching process is omitted, bunching efficiency is improved, and bunching cost is reduced. Besides, the yield can be increased, and the defective rate is reduced. In the later maintenance process, detachment can be completed in simple steps, subsequent maintenance is extremely convenient, and use and maintenance cost is reduced.

Owner:HUATING HEFEI POWER TECH

Continuous type welding-free lead storage battery pole plate and manufacturing method thereof

PendingCN108649187AImprove manufacturing process efficiencyEasy to processFinal product manufactureElectrode carriers/collectorsEngineeringMonomer

The invention discloses a continuous type welding-free lead storage battery pole plate and a manufacturing method thereof. The continuous type welding-free lead storage battery pole plate is characterized in that a continuous type lead storage battery grid is adopted and comprises a plurality of plate coating areas (2); the adjacent plate coating areas (2) are connected by a connecting area (3); one end or both ends of the continuous type lead storage battery grid are provided with terminal areas (1); the plate coating areas (2) and the connecting areas (3) are integrally formed; each plate coating area (2) of the continuous type lead storage battery grid is coated with an active matter layer, so as to obtain a pole plate area. The continuous type welding-free lead storage battery pole plate has the advantages that by adopting the integrated continuous type design, the procedure of welding multiple pole plates in a pole plate group of a single unit in the production process of the storage battery is eliminated, and the serial and parallel welding procedures of bridge-crossing welding, wall-penetrating welding and the like between multiple units of the storage battery are also eliminated; the lead usage amount of the storage battery is effectively reduced, the piece falling and welding missing in the pole plate group and between the units of the storage battery are avoided, andthe quality and reliability of the storage battery product are effectively improved.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Antenna assembly and electronic device using same

InactiveCN101728634AElimination of welding processDoes not affect appearanceAntenna supports/mountingsRadiating elements structural formsResonanceCoupling

Owner:FUTAIJING PRECISION ELECTRONICS BEIJING

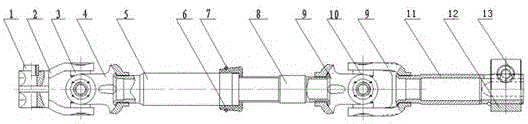

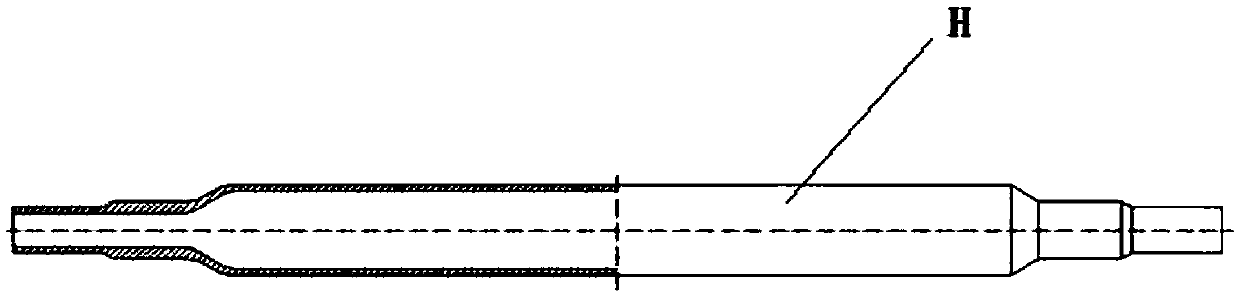

Automobile steering lower transmission shaft assembly without welding structures

InactiveCN106218706ASmooth rotationImprove securityMechanical steering gearsInterference fitDrive shaft

The invention provides an automobile steering lower transmission shaft assembly without welding structures. The automobile steering lower transmission shaft assembly comprises a telescopic transmission device, an upper universal joint and a lower universal joint, wherein the upper universal joint and the lower universal joint are arranged at two ends of the telescopic transmission device; the upper universal joint comprises two sleeve-loading universal joint forks and an upper universal joint cross shaft arranged between the two sleeve-loading universal joint forks; an upper locking nut is in interference fit with a locking sleeve; the locking sleeve is axially fixed on a connection sleeve; the connection sleeve is fixed on the sleeve-loading universal joint forks; the lower universal joint comprises a sleeve-unloading universal joint fork, a lower universal joint fork and a lower universal joint cross shaft arranged between the sleeve-unloading universal joint fork and the lower universal joint fork; a lower locking nut is in interference fit with the lower universal joint fork; the telescopic transmission device comprises a lower spline shaft; the lower spline shaft is fixed on the sleeve-loading universal joint forks, and is in sliding connection with a lower spline sleeve; a dustproof cover is fastened on the lower spline sleeve, and is fixed on the sleeve-unloading universal joint fork. The automobile steering lower transmission shaft assembly without the welding structures has the advantages that the welding process is eliminated, the problem of welding deformation of workpieces is solved, the overall structure is firm, the process is simple, the product quality is improved, and the production cost is reduced.

Owner:JIANGSU JINYE AUTO PARTS

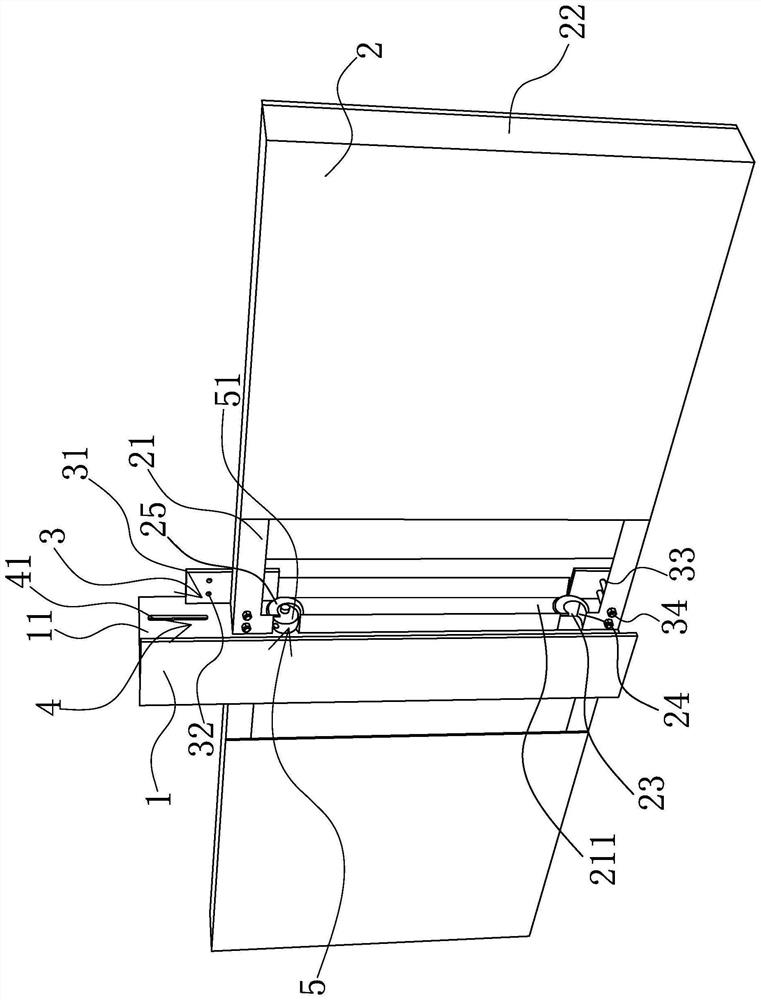

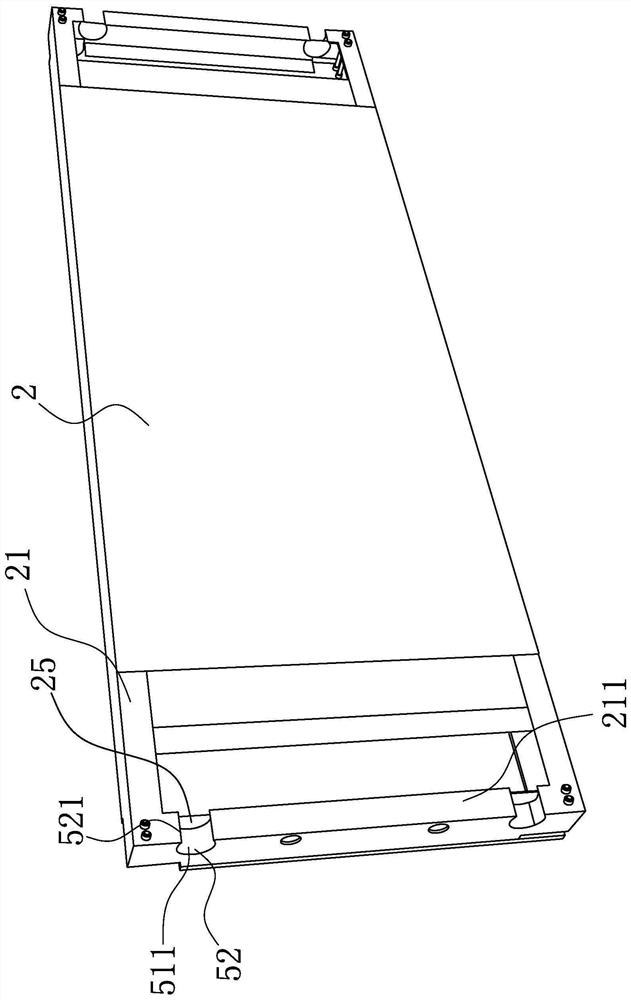

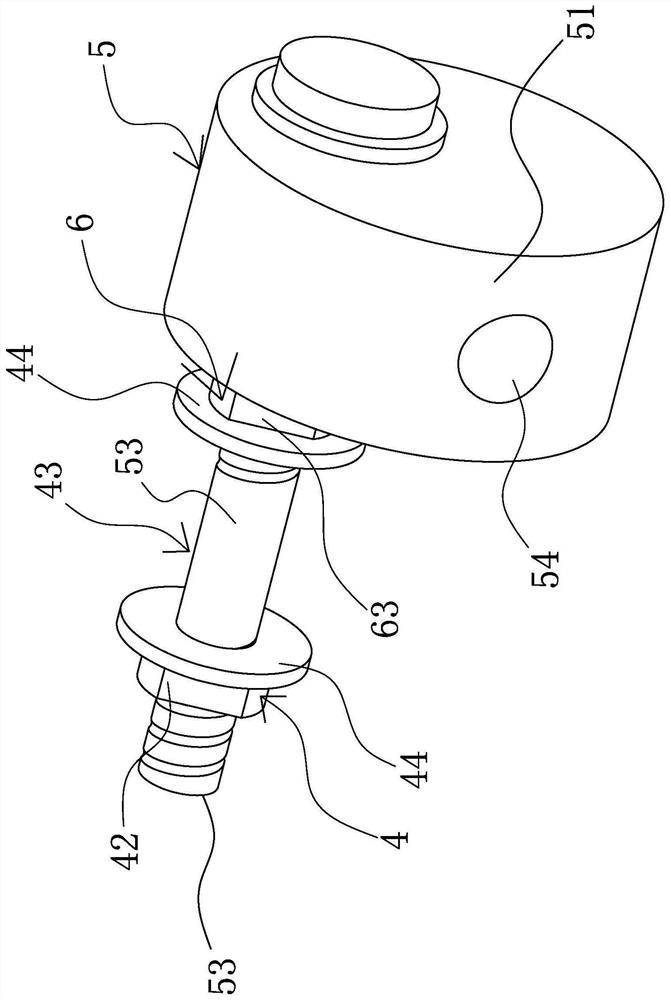

Wallboard welding-free easy-assembly system

PendingCN113404187AThe installation process is simple and convenientSimple structureWallsClassical mechanicsBolt connection

The invention relates to a wallboard welding-free easy-assembly system. The problem that an existing wallboard is inconvenient to install is solved. The wallboard welding-free easy-assembly system comprises a stand column, at least one wallboard is arranged on at least one side of the stand column, an auxiliary positioning structure is arranged between the stand column and the wallboard, an eccentric wheel assembly with at least one rotationally-arranged eccentric wheel body is arranged on the stand column through a vertically-adjustable mounting structure, a positioning groove corresponding to the eccentric wheel body is formed in the side, close to the stand column, of a wall body, the eccentric wheel body is movably arranged in the positioning groove, and when the eccentric wheel body rotates circumferentially under the action of external force, the circumferential outer side of the eccentric wheel body abuts against the positioning groove, so that the wallboard is clamped on one side of the stand column. The system has the advantages that the wallboard and the stand column are simple and convenient to install and adjustable in vertical position, the stand column and the wallboard are clamped and positioned by abutting the circumferential outer side of the eccentric wheel body against the positioning groove in one side of the wallboard, bolt connection and welding procedures of the stand column and the wallboard are omitted, the construction amount is small, the procedures are simple, and the installation efficiency is high.

Owner:CHANGDA STEEL STRUCTURE CO LTD

A continuous lead-acid battery grid and a manufacturing method thereof

PendingCN109004237AElimination of welding processReduce the amount of lead usedElectrode carriers/collectorsEngineeringCross bridge

The invention relates to the technical field of chemical power supply materials, in particular to a continuous lead-acid battery grid and a manufacturing method thereof, comprising a plurality of coating plate regions (2), wherein adjacent coating plate regions (2) are connected through connecting regions (3), one end or both ends of the grid are provided with terminal regions (1), and the coatingplate regions (2) and the connecting regions (3) are integrally formed. The continuous lead-acid battery grid adopts the integrated continuous design, which eliminates the welding process of multipleplates in the counter plate group of a single cell in the production process of the battery, and also eliminates the series-parallel welding process such as the cross-bridge welding and the through-wall welding between multiple cells of the battery. In this way, not only the lead consumption of the battery is reduced, but also the phenomena of chip dropping and welding leakage do not appear in the electrode plate group and between the cells of the battery, which effectively improves the product quality and reliability of the battery.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

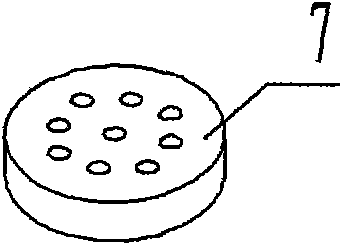

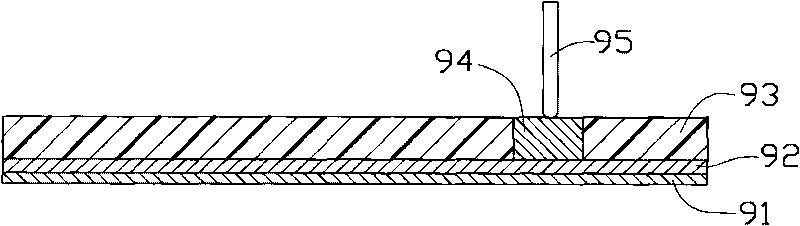

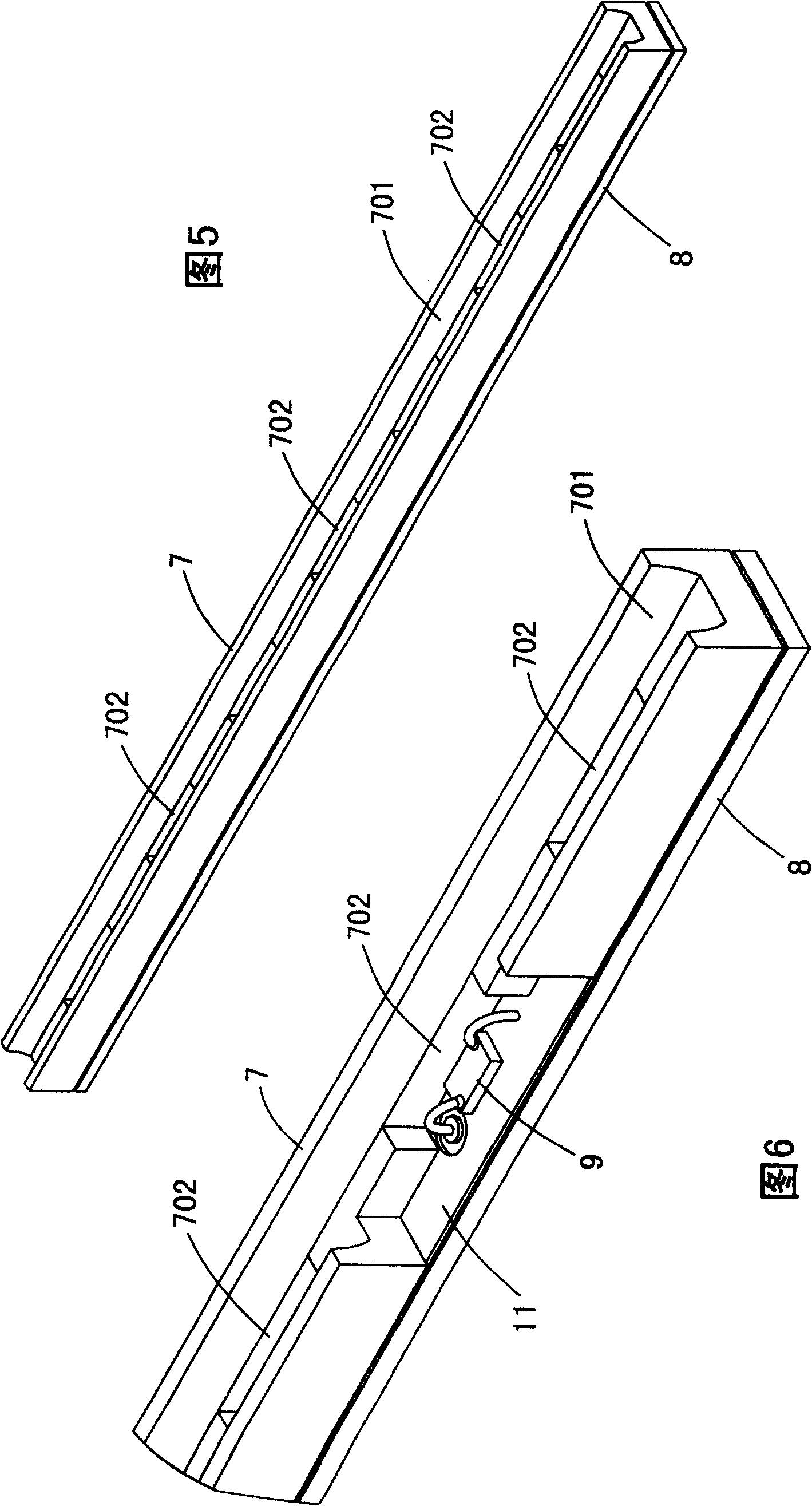

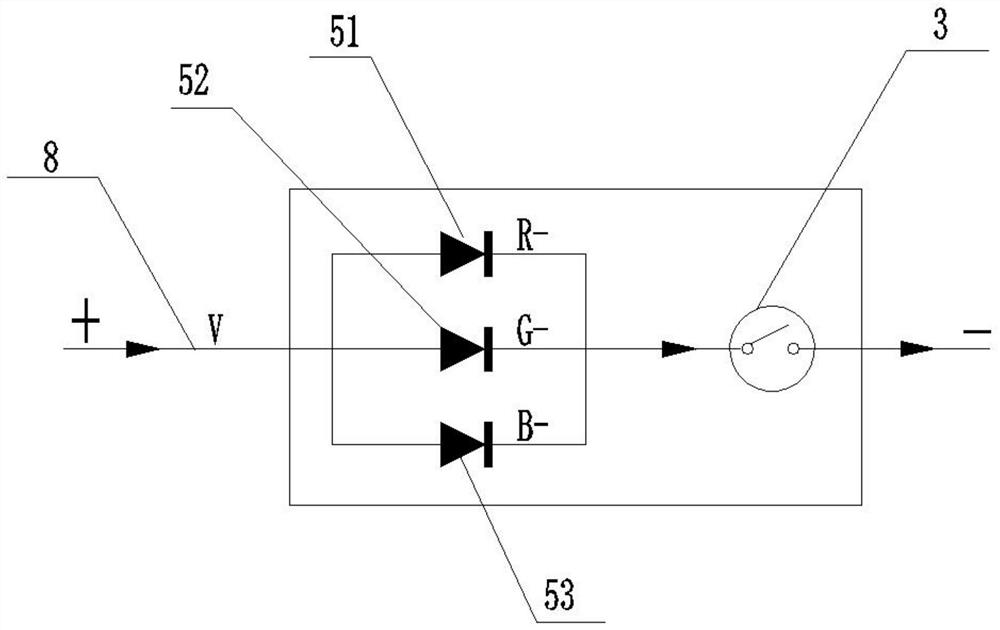

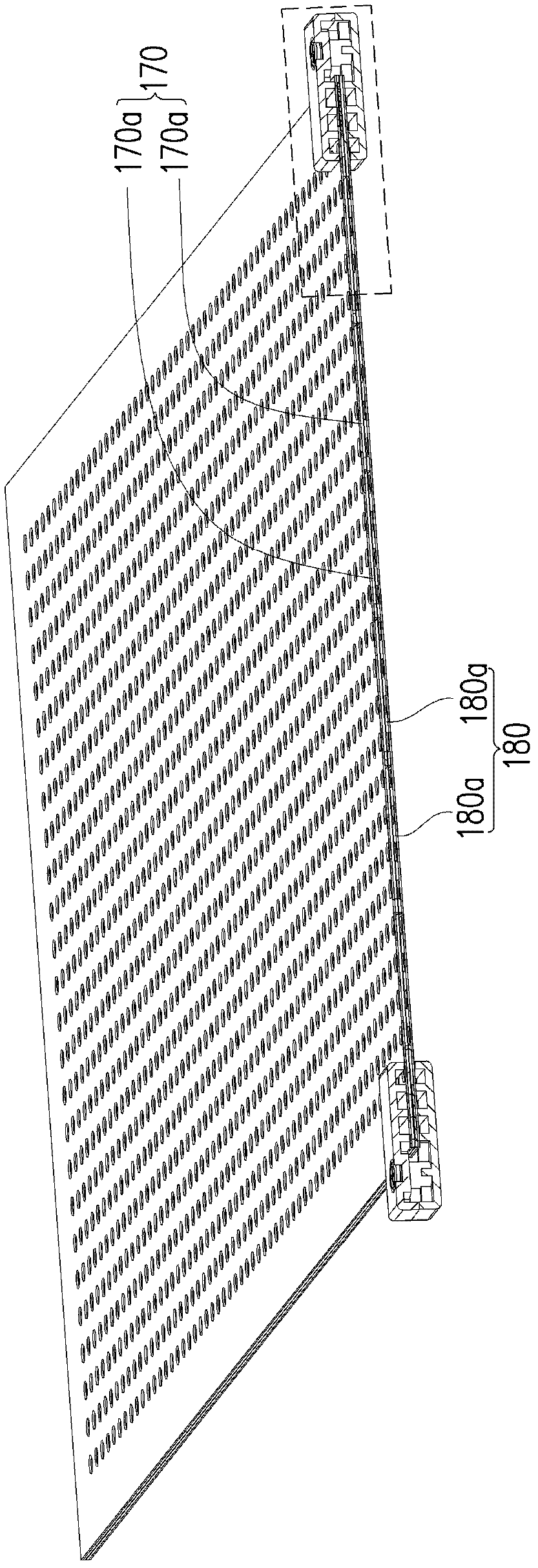

Lighting stick with LBD wafer

InactiveCN100423257CElimination of welding processReduce the number of particlesPoint-like light sourcePortable electric lightingLight-emitting diodeElectrical and Electronics engineering

A light emitting stick having LED chips (9) is disclosed. The light emitting stick comprises a strip shaped frame (7), a circuit board (8) and a plurality of LED chips (9). The upper part of the frame has a groove (701), and the lower part of the frame has a plurilty of vertical holes (702). The top of each of the vertical holes (702) and the bottom of the groove (701) are feedthrough. A negative pole plate (11) is placed on the upper surface of the circuit board (8), and has a plurality of throughholes (111). The position of the throughholes (111) corresponds to the position of the vertical holes (702). The circuit board (8) has a pluralityof positive pole pads (12). The positive pole pads (12) are exposed from the throughholes (111) on the negative pole plate (11), respectively. The bottom surface of the frame (7) bonds to the negative pole plate (11). The LED chips (9) are embedded into the vertical holes (702) of the frame (7), respectively. The positive terminal wires (902) of the LED chips (9) are connected to the positive terminal wires (902) of the positive pole pad (12) one by one, and the negative terminal wires (901)of the LED chips (9) are connected to the negative pole plate (11) of the circuit board (8) one by one. The inner walls of the groove (701) form reflective walls.

Owner:黄虎钧

Machine for manufacturing electrode tape

ActiveCN102786882BFunctionalDisadvantages of Avoiding DestructionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationAdhesive materialsMechanical engineering

A machine (600, 700, 800) for manufacturing an electrode tape (100, 200, 300, 660, 760, 860) is disclosed. The machine (100, 200, 300, 660, 760, 860) includes a conveyor (610, 710), a conductive structure coil (620, 720, 820), an adhesive material supply unit (630, 730) and a curing unit. The conveyor (610, 710) includes a molding belt (611, 711) with at least one groove (611a, 611b) and a roller (612, 613, 712, 713) used to drive the molding belt (611, 711). The conductive structure coil (620, 720, 820) is adapted to provide a conductive structure (102, 202) to the at least one groove (611a, 611b) of the molding belt (611, 711). The adhesive material supply unit (630, 730) is adapted to provide an adhesive material (101, 201, 301, 661) to a surface of the molding belt (611, 711). The curing unit is adapted to cure the adhesive material (101, 201, 301, 661) provided on the surface of the molding belt (611, 711) into a film.

Owner:NEO SOLAR POWER CORP

Combined knockout core structural investment pattern die bundling core

InactiveCN101564757BElimination of welding processConsistent sizeFoundry mouldsFoundry coresEngineeringSolid core

The invention discloses a combined knockout core structural investment pattern die bundling core, comprising a positioning mandrel, a drawing flap, a mould flap, a cramping device and a terminal base.The core is divided into nine flaps whose contact sides are parallel along the axial direction of the mould knockout core according to the mode of the Chinese character of ''Jing'', wherein the fourcut surface rectangle flaps at the axial center are positioning mandrel, three cut surface flaps are drawing flaps and two cut surface flaps are mould flaps. The bundling solid core combined by nine flaps participates the investment pattern forming by inserting into the die, and draws out the positioning mandrel, the drawing flap and mould flap in turn during knockout. The combined knockout core structural investment pattern die bundling core avoids the welding procedure for the special form products in batch production by drawing the core in sequence, thus achieving the consistent dimension,high efficiency and low cost.

Owner:宁波双海机械制造有限公司

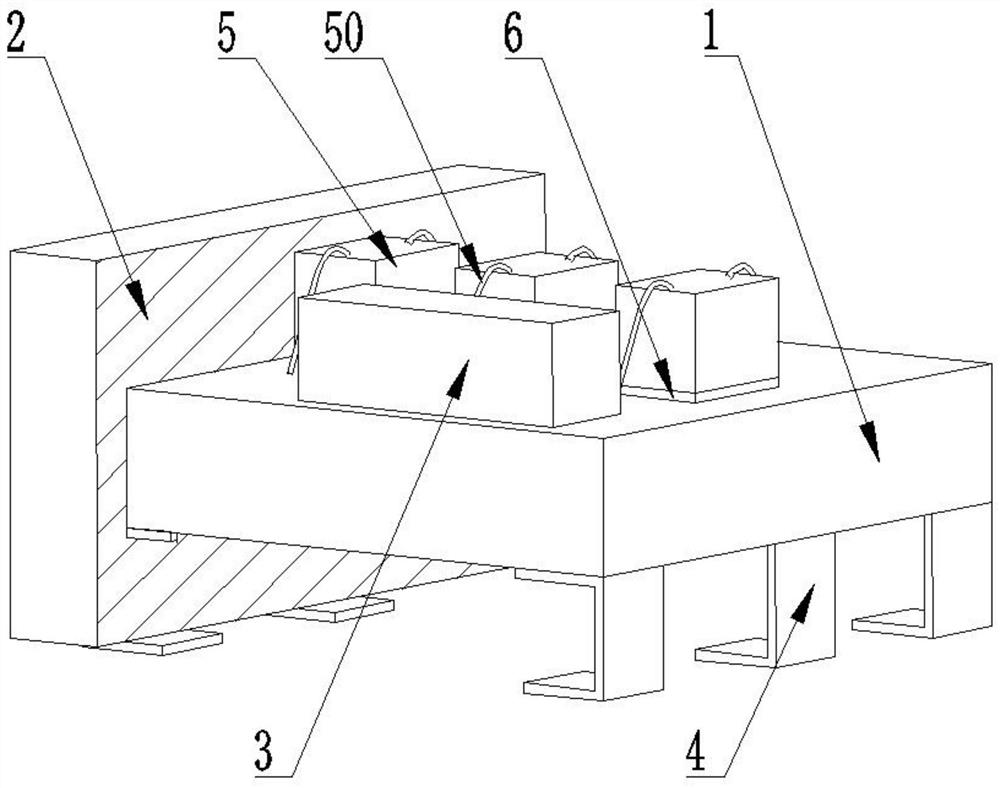

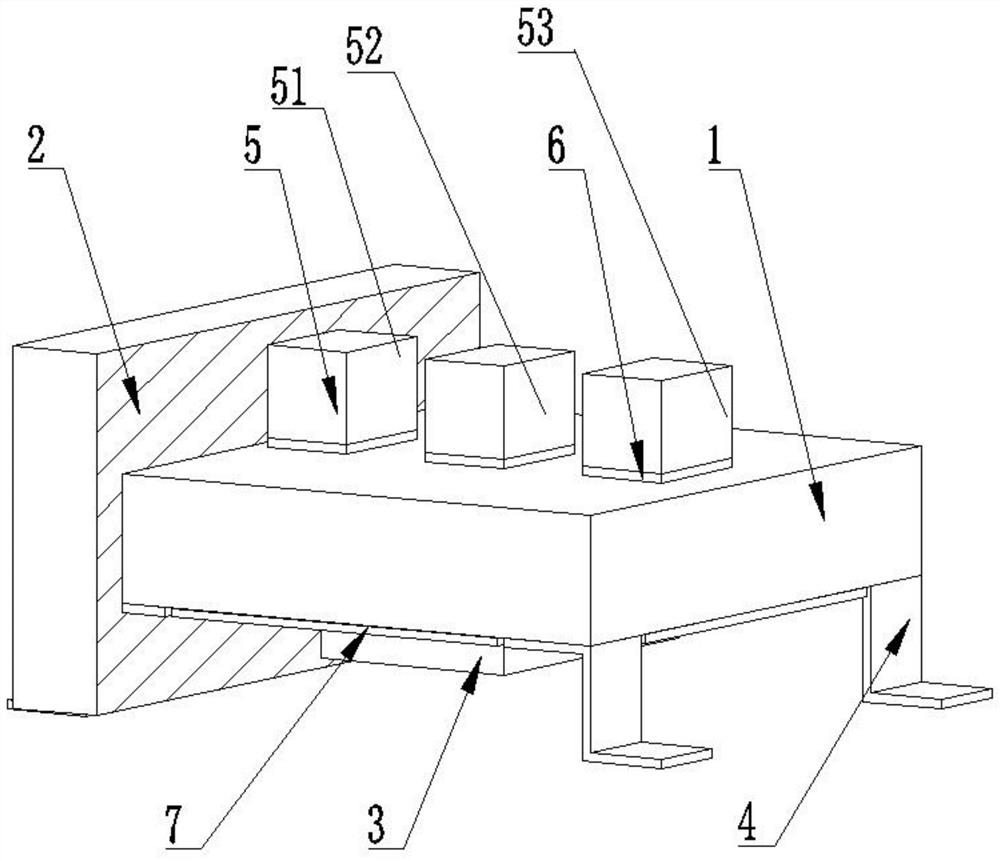

LED driving power supply circuit board with test apparatus

InactiveCN104880662AElimination of welding processIncrease productivityElectronic circuit testingElectric light circuit arrangementTransformerComputer module

The invention discloses an LED driving power supply circuit board with a test apparatus. The LED driving power supply circuit board with the test apparatus comprises the LED driving power supply circuit board. The circuit board comprises a transformer, a control circuit module and a circuit substrate, wherein the transformer and the control circuit module are electrically connected with the circuit substrate, the two surfaces of the two ends of the circuit substrate are each provided with an electrical contact sheet, the electrical contact sheets are rectangular soldering tin layers each having a thickness of 0.2 cm, metal springs are fixed on the rectangular soldering tin layers, and the circuit substrate is also provided with an indicating lamp. When a tester is connected with the electrical contact sheets, the indicating lamp can display whether the circuit board is at a normal state or a failure state. According to the invention, the two surfaces of the two ends of the circuit board are respectively provided with the electrical contact sheets, and such a structure can eliminate a welding process, directly test the circuit board and improve the production efficiency.

Owner:徐新权

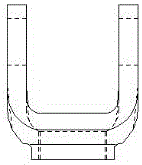

A new type of aluminum profile floating plate

ActiveCN110723424BEliminate internal stressImprove bending resistanceGeneral water supply conservationLarge containersFlangeEngineering

The invention discloses an aluminum profile floating plate, comprising a floating plate body, the floating plate body includes a plurality of floating box elements, the floating box elements are set to be extruded from aluminum profiles at one time, and the plurality of floating box elements are arranged as Connected by snaps, the floating box element has left and right splicing sides, the left and right splicing sides have a first side edge and a second side edge, the first side edge has a hook-shaped flange, and the second side has a concave that can accommodate the hook-shaped flange. The pontoon element and its adjacent pontoon element are arranged to be spliced on the left and right splicing sides through the cooperation of the hook-shaped flange and the groove.

Owner:CHINA PETROLEUM & CHEM CORP +1

LED lamp bead with built-in drive IC

PendingCN112786578ASolve the effect of lighting viewing angleOptimize layoutSolid-state devicesIdentification meansWaferingEngineering

The invention discloses an LED lamp bead with a built-in drive IC. The LED lamp bead comprises a PCB, a colloid, an IC wafer, pins, an LED wafer and insulation paste. The PCB is connected with the colloid, the LED wafer is arranged on the PCB, and the LED wafer is connected with the PCB through the insulation paste; the LED wafer is arranged on the front surface of the PCB and comprises a red LED wafer, a green LED wafer and a blue LED wafer, and the red LED wafer, the green LED wafer and the blue LED wafer are linearly arranged; the IC wafer is arranged on the back face of the PCB, the pins are connected with the PCB, and the pins comprise outwards-turned pins. According to the invention, the LED lamp bead with the built-in drive IC is low in power consumption, prevents heat focusing, improves the product quality, reduces the process difficulty and improves the brightness of the LED lamp bead.

Owner:深圳市伽弥科技有限公司

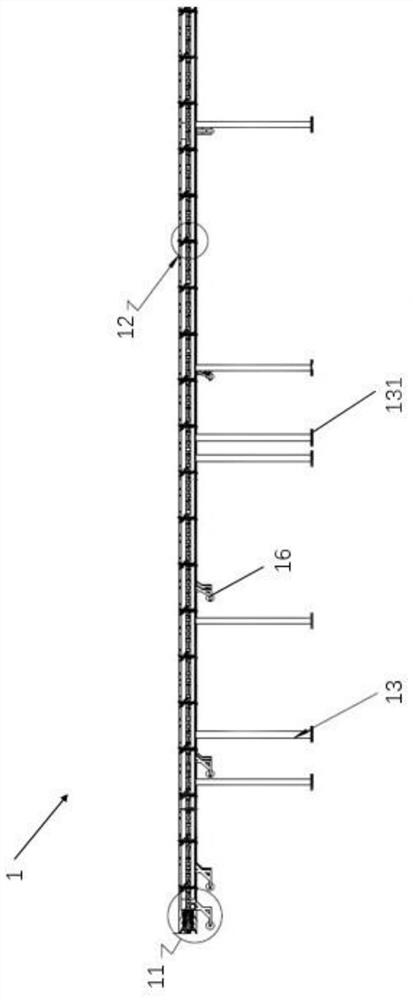

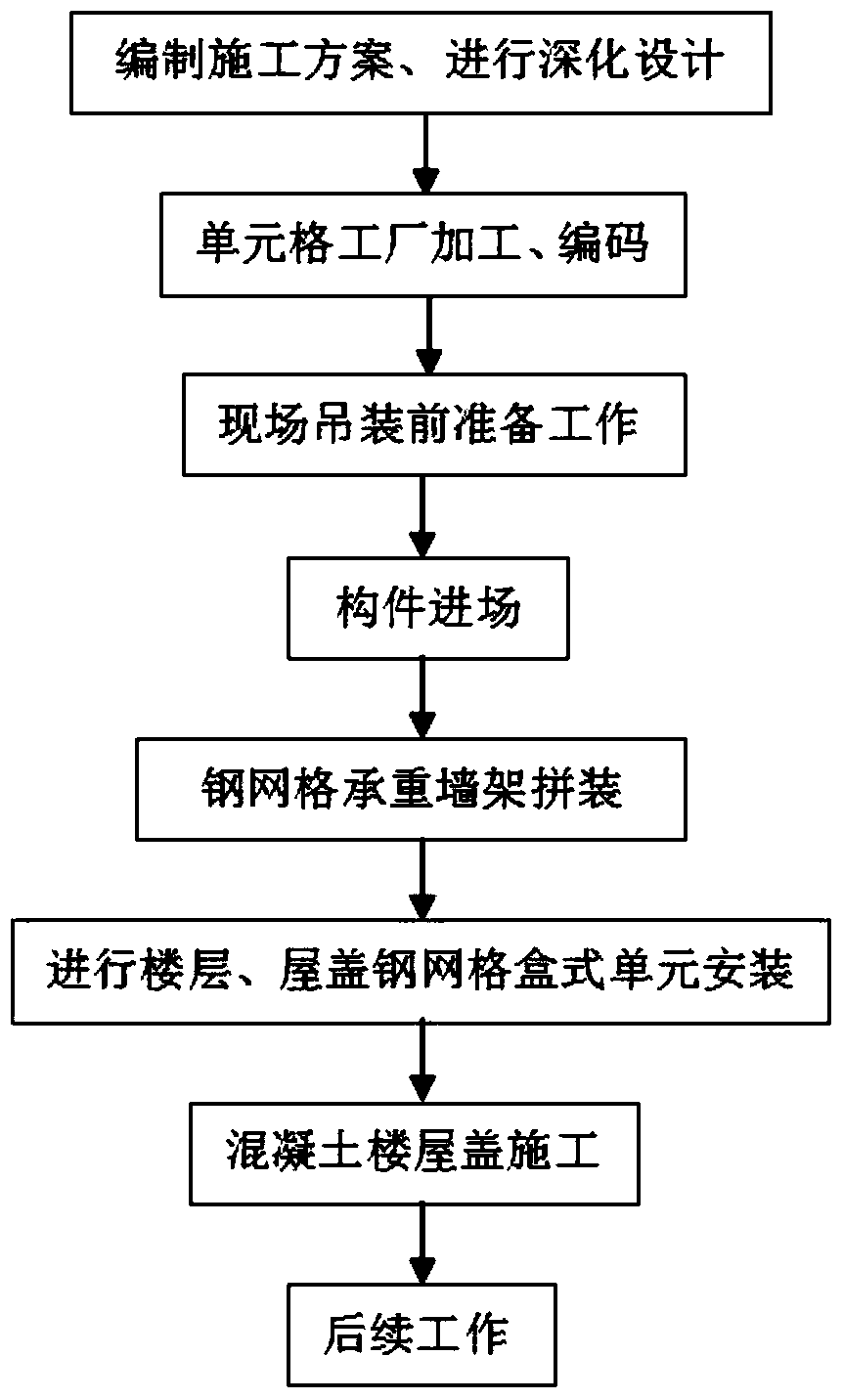

A construction method for a multi-layer large-span assembly integral space steel grid box structure factory building

ActiveCN105756380BFast constructionShort cycleBuilding material handlingIndustrial buildingsEarthquake resistanceArchitectural engineering

The invention discloses a construction method of a multi-layer large-span assembled integral space steel grid box-type structure factory building. The method comprises the following steps of factory building structure division, steel mesh unit grid processing, site construction preparation, component preparation, bearing wall rack assembly, operation platform erection, steel mesh unit grid hoisting, concrete roof cover construction and the like. The construction method is high in construction speed and short in period, is capable of simultaneously realizing concrete part construction and steel structure component assembly, greatly reducing the construction expenses and greatly shortening the construction time; the factory building constructed by the method has the advantages of excellent lateral stiffness, small structural top displacement, good anti-seismic property, no indoor beam and column, free division of a habitable room, convenience in use, beautiful appearance, high utilization ratio and the like.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

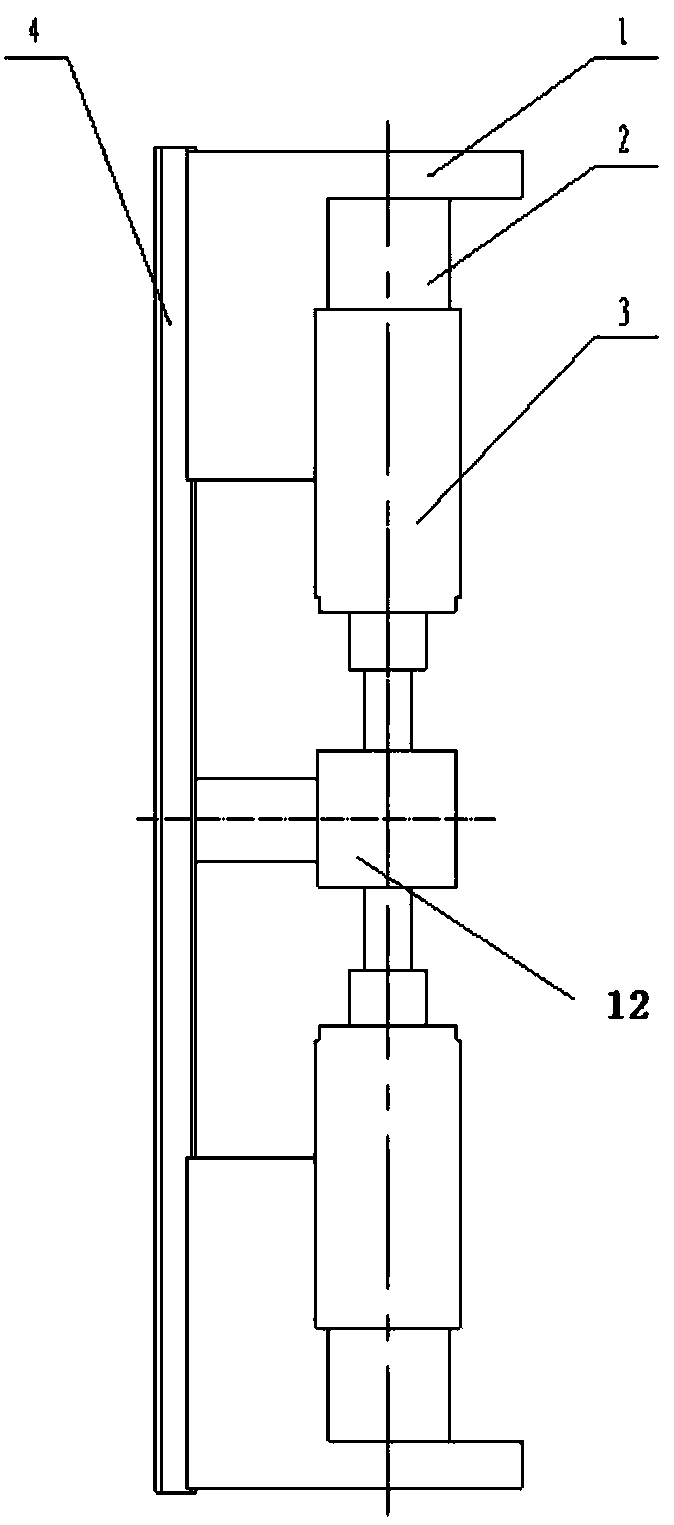

Forming equipment for axle head of drive axle housing

ActiveCN106424528BEasy to operateElimination of welding processRailway componentsVehicle componentsEngineeringMechanical engineering

The invention relates to a forming method and a forming device for an axle head of a driving axle housing. The forming method comprises heating two ends of a metal tube blank, and then upsetting the two ends of the tube blank to thicken local tube walls of the two ends of the tube blank; after the upset tube blank is cooled, performing once reducing on both ends of the tube blank, wherein the once reducing comprises: after heating the two ends of the tube blank to a preset temperature field, driving a first mold core with a predetermined shape to predetermined positions in the two ends of the pipe blank; pushing an once reducing die to extrude the two ends of the tube blank, such that the two ends of the tube blank are reduced to form predetermined shape profiles; pulling the first mold core out of the two ends of the tube blank, wherein the first mold core can perform inner cavity shaping on the two ends of the tube blank; and withdrawing the once reducing die. Under a premise of ensuring that the axle head and the axle housing are integrated, an inner cavity of the axle head is through and flat, a die attaching property of an appearance of the axle head is improved, a metal streamline of the inner cavity of the axle head is combed, and the shape and size precision and mechanical property of the axle housing are greatly improved.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

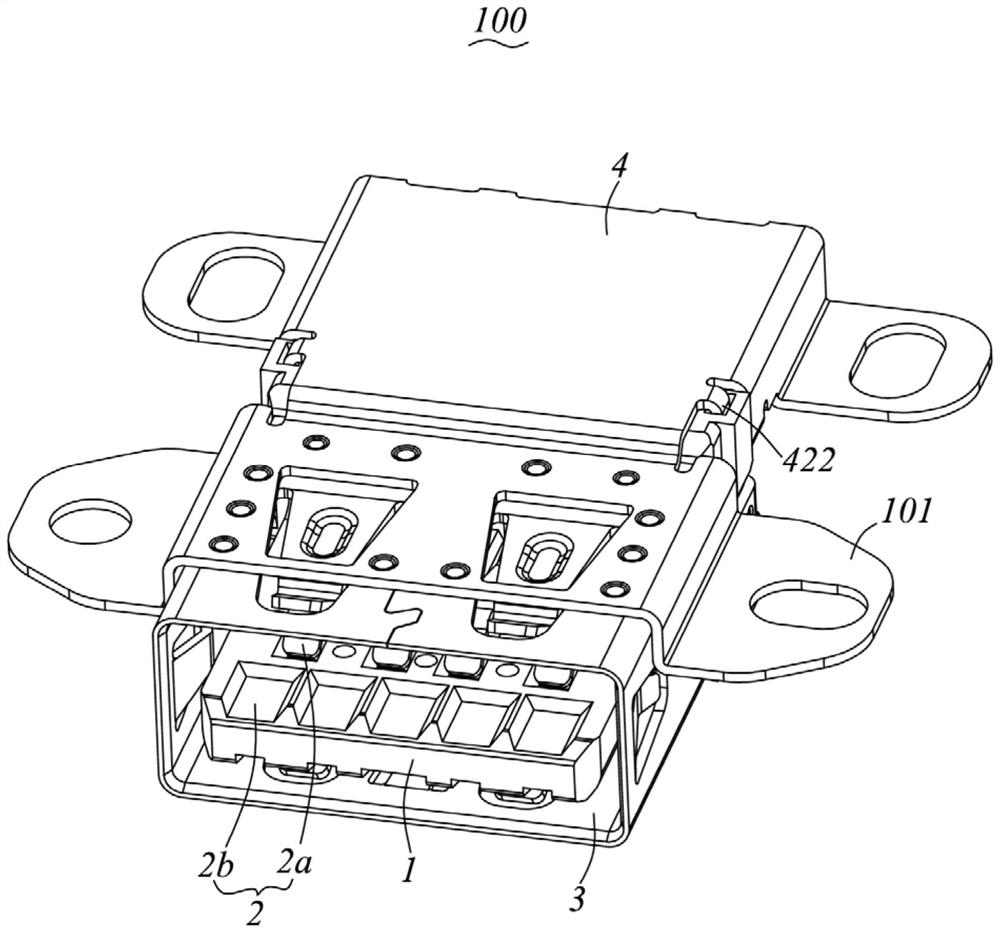

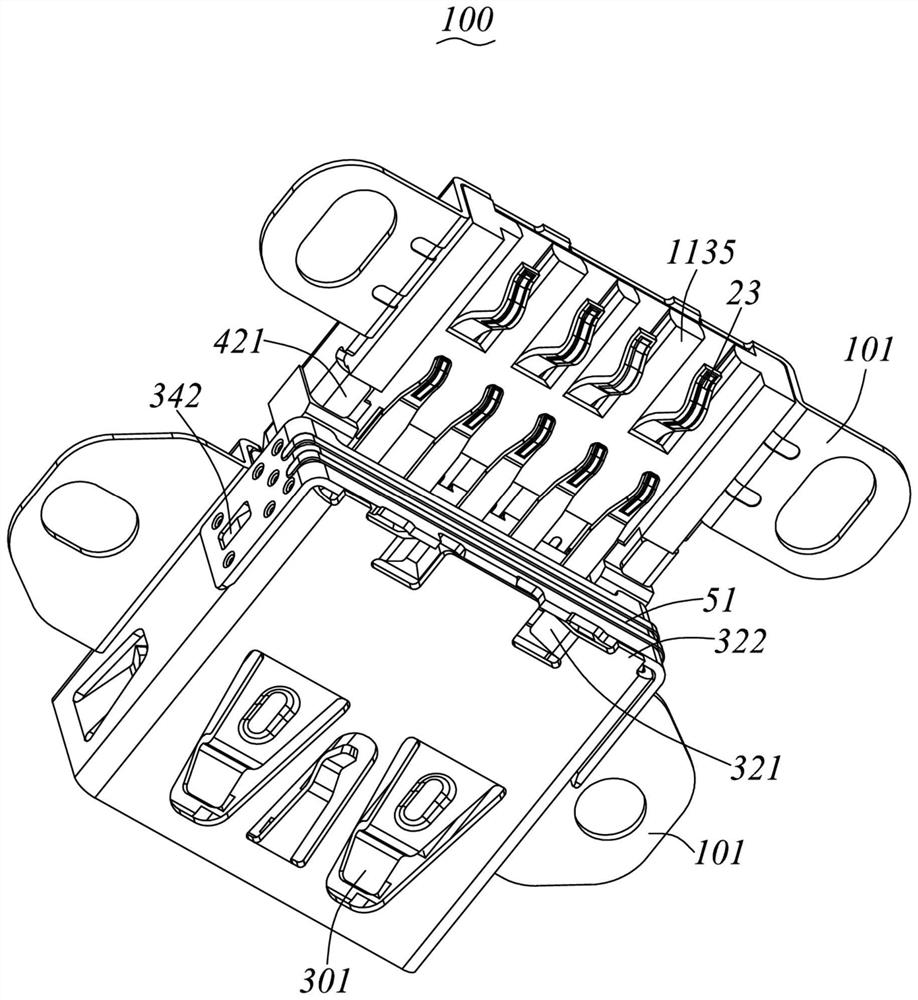

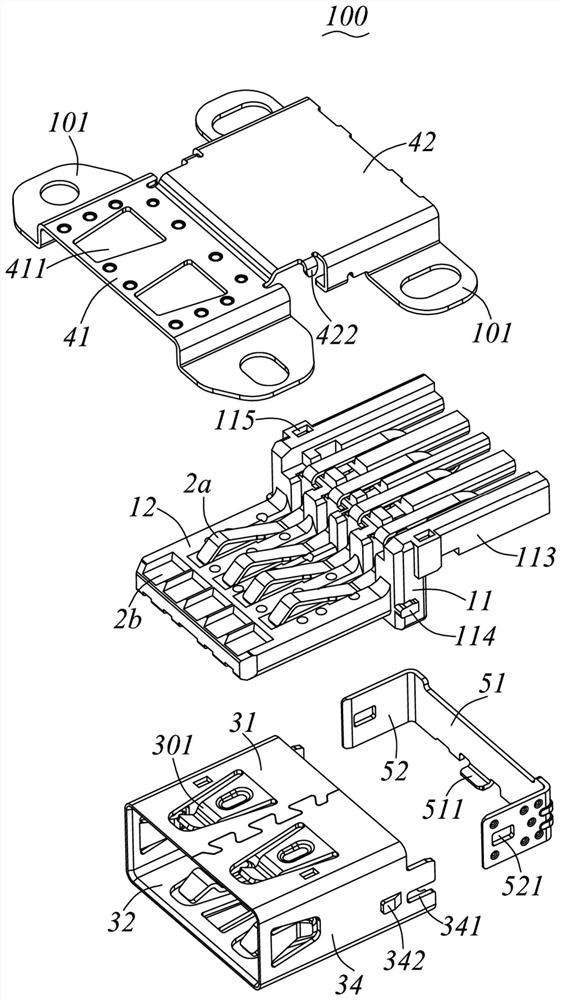

Electric connector

PendingCN113193396AImprove processing efficiencyElimination of welding processCoupling contact membersElectrical connectionEngineering

The invention provides an electric connector, and the connector comprises an insulation body, a plurality of conductive terminals and a metal shell; the insulation body is provided with a base part and a tongue plate, each conductive terminal is provided with a contact part protruding out of the surface of the tongue plate, a fixed part fixedly held in the insulation body and a tail part positioned at the rear end of the insulation body; the metal shell is provided with an accommodating space which is opened forwards, the tongue plate is protruded and exposed in the accommodating space, the conductive terminals comprise a group of first conductive terminals and a group of second conductive terminals, each first conductive terminal is provided with a bent first contact part which is protruded and exposed on the tongue plate, each second conductive terminal is provided with a straight second contact part which protrudes out of the tongue plate, the second contact part is located in front of the first contact part in the front-back direction, the tail part extends backwards from the fixing part and is exposed outside the base part, and the tail part is bent so as to be in elastic contact with an external circuit board in a welding-free manner. The electric connector is convenient to electrically connect.

Owner:ALLTOP ELECTRONICS SU ZHOU

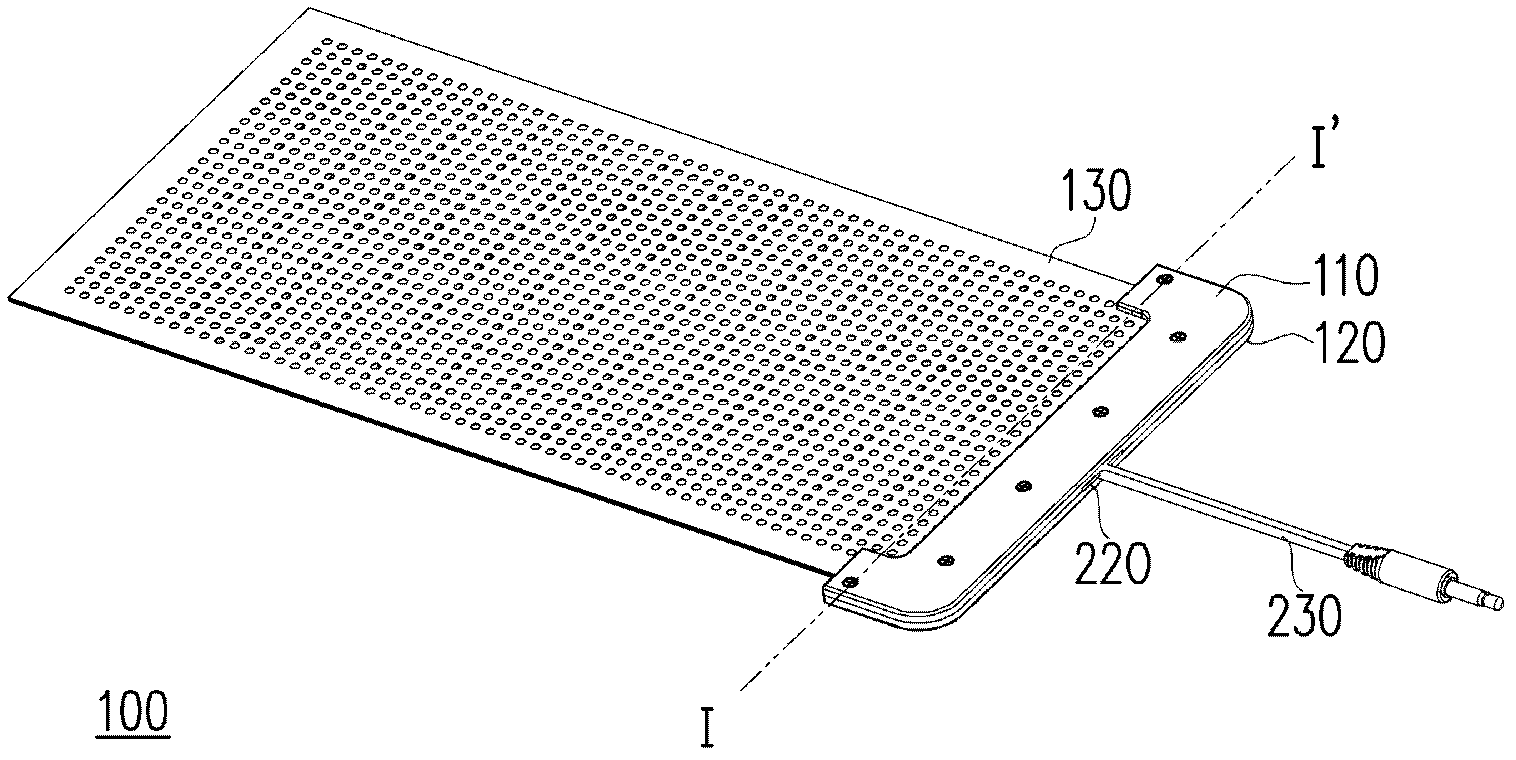

Planar loudspeaker device

InactiveCN103209374AElimination of welding processLow costElectrical transducersEngineeringLoudspeaker

The invention relates to a planar loudspeaker device which comprises an upper casing, a lower casing, a planar loudspeaker single body, a conductive electrode group and more than one locking piece. The upper casing is provided with a first positioning portion, and the lower casing is arranged under the upper casing and provided with a second positioning portion. The planar loudspeaker single body comprises more than one hole electrode and a vibrating diaphragm. Each hole electrode is provided with a plurality of holes, and the hole electrodes and the vibrating diaphragm are clamped to form a plurality of air cavities. The conductive electrode group is connected with the planar loudspeaker single body and used for providing a power supply signal for transmitting sound. The locking piece is used for fixing the upper casing and the lower casing and clamping the planar loudspeaker single body and the conductive electrode group.

Owner:FORTUNE GRAND TECH

Method for welding coiler on large container

ActiveCN100496847CNice appearanceQuality improvementArc welding apparatusButt jointContinuous operation

The process of welding coil onto large container includes the following steps: 1. machining plate into semi-circular pipe; 2. machining the semi-circular pipe into bend pipe for the container cylinder in the required diameter; 3. winding the bend pipe onto the surface of the container cylinder; and 4. welding the coil onto the container. The present invention has continuous operation, short production time, elimination of circumferencial weld seal, less leakage possibility and good appearance of the coil.

Owner:上海贤达美尔森过程设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com