Electrode tape, solar cell module and methods for manufacturing the same

A technology for solar cells and electrode tapes, applied to conductive materials, circuits, adhesives, etc. dispersed in non-conductive inorganic materials, can solve problems such as microcracks on the surface of crystalline silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

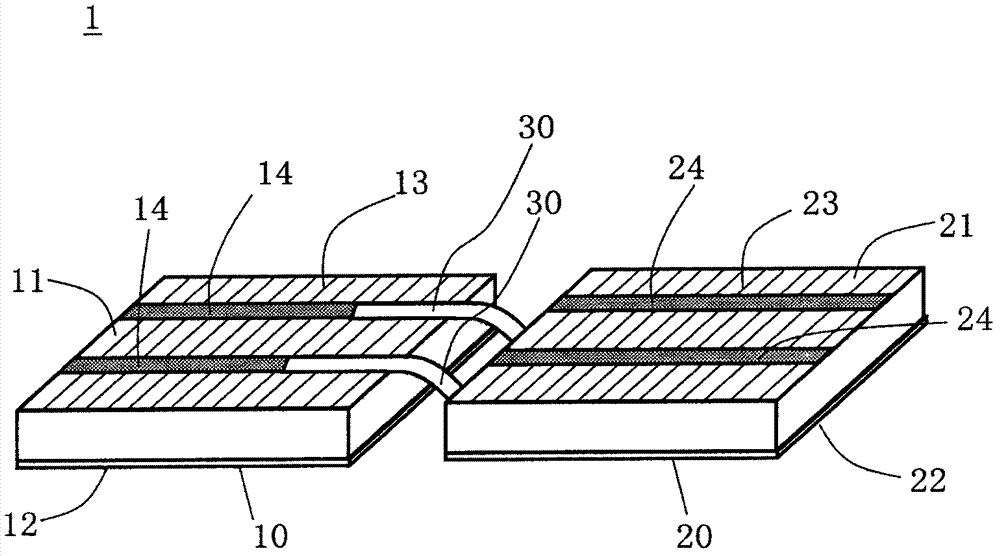

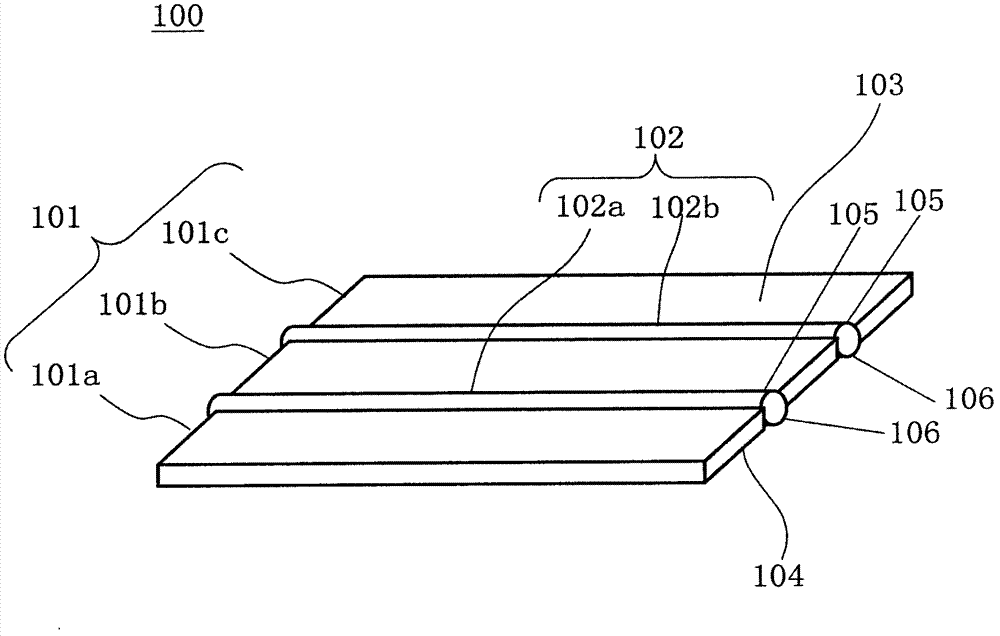

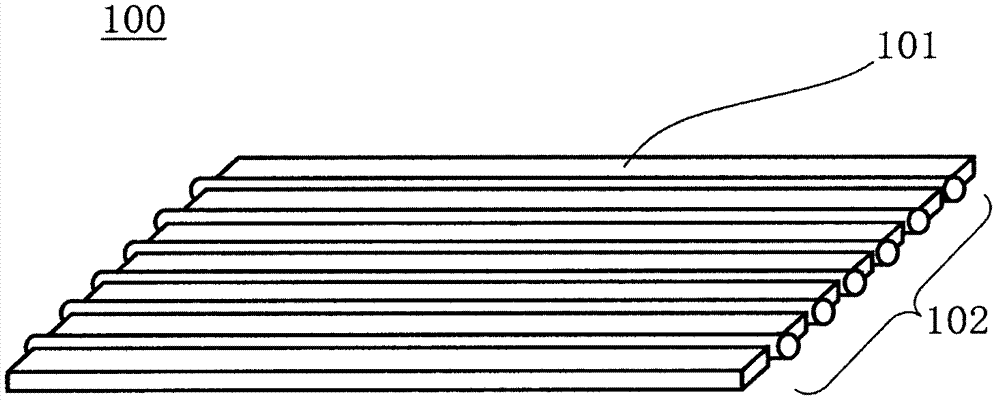

[0158] Embodiments of the present invention will be described below by way of example with reference to the accompanying drawings. The components shown in the drawings do not represent the actual size of the components, and their thickness, width, or length, etc. are drawn exaggeratedly for the sake of illustration. Meanwhile, in all the drawings, the same component symbols represent the same components.

[0159] In this specification, "electrode tape" refers to a tape having electrodes on its structure. "Electrode" refers to an electrically conducting structure. "Tape" means a film (Film), strip (Strip), sheet (sheet) and other similar materials including adhesive materials, usually continuously rolled into a bundle (roll) for storage, but can also be cut into pieces if necessary. After appropriate length, stack and store, or store in other appropriate ways. At normal temperature, the surface of this film can be sticky or non-sticky. A film on a non-sticky surface at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com