Forming equipment for axle head of drive axle housing

A drive axle housing and forming equipment technology, which is applied to railway car body parts, transportation and packaging, vehicle parts, etc., can solve the problems that the shaft head shape and dimensional accuracy are difficult to guarantee, and the penetration is straight, etc., to achieve a small footprint, Increased fit and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The forming method and forming equipment of the integrated drive axle housing axle head of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] However, those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

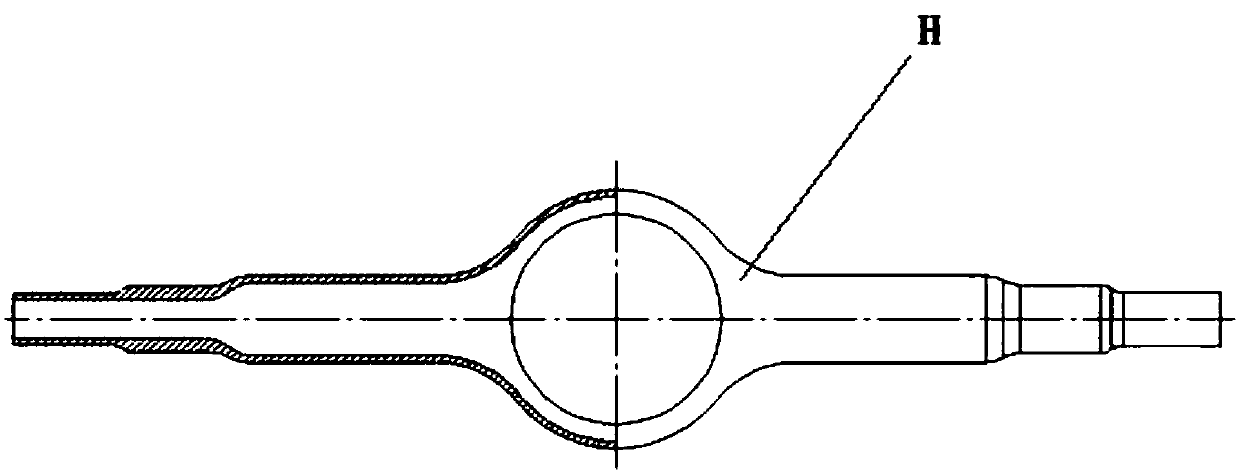

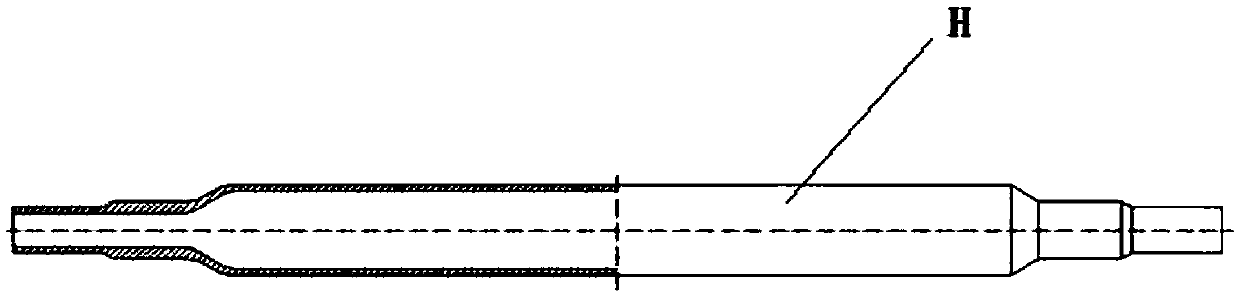

[0050] figure 1 A structural schematic diagram of the overall drive axle housing of the automobile is shown, figure 2 Schematic diagram of the structure of the seamless steel pipe for forming the integral drive axle housing of the automobile after forming the axle heads at both ends. Depend on figure 1 It can be seen that both ends of the transaxle housing H are formed as stepped shafts.

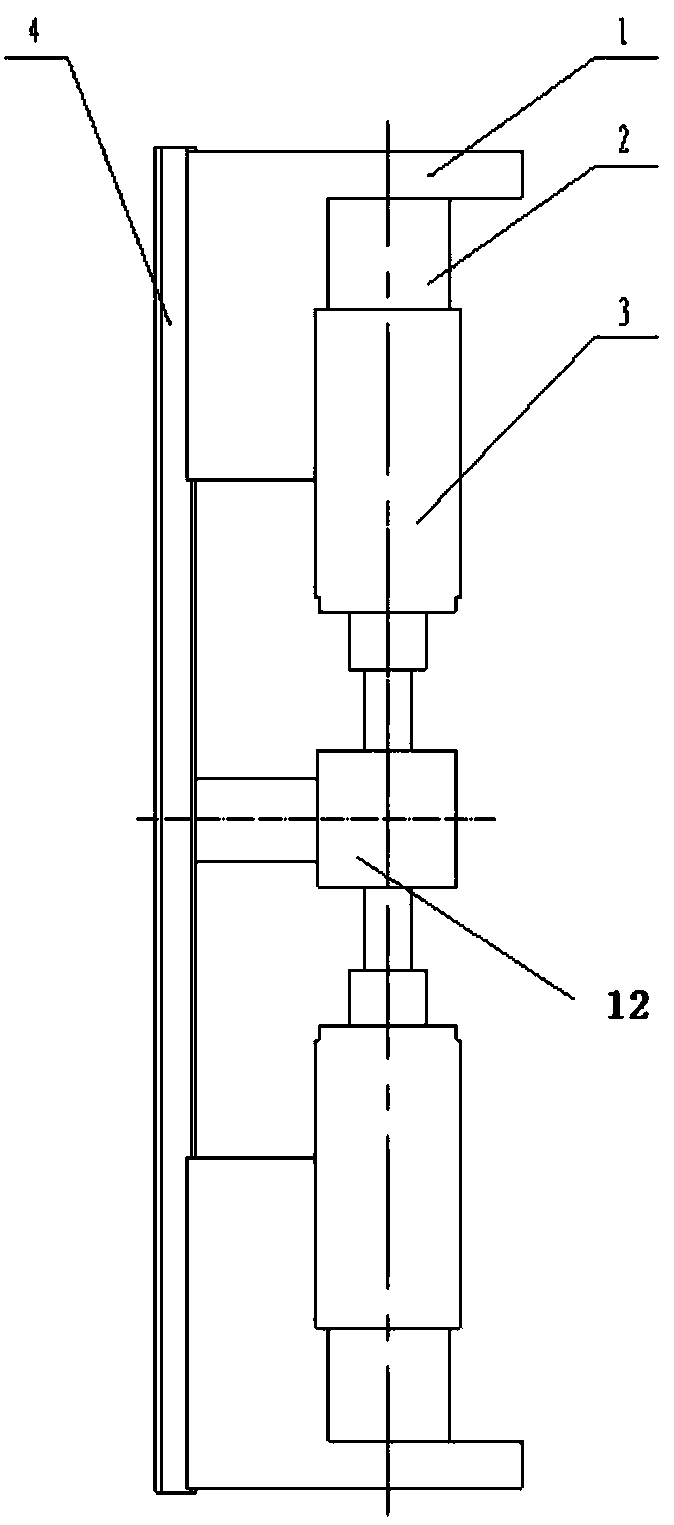

[0051] image 3 It is a front view of the forming equipment for forming the axle heads at both ends of the integral drive axle housing according to the present invention. Such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com