Method for welding coiler on large container

A processing method and technology for large containers, applied in the field of mechanical processing, can solve the problems of unreliable quality, labor-intensive waste, complicated manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

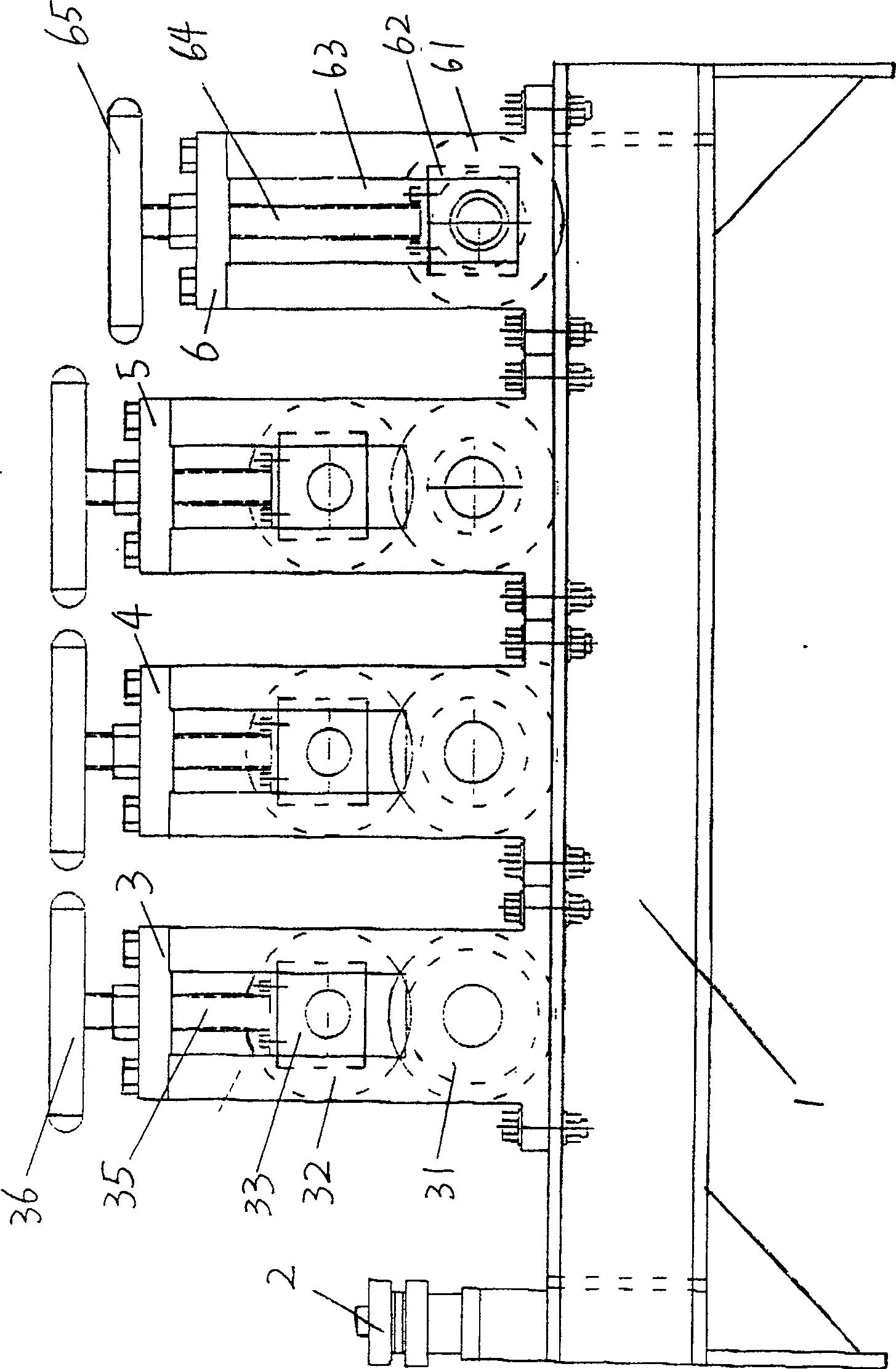

[0005] A processing method for welding a coiled pipe on a large container, which is characterized in that the method includes the following steps: A, processing the strip into a semicircular pipe; B, processing the semicircular pipe into an elbow with the required diameter of the container cylinder ; C. Wrap the elbow directly on the surface of the container cylinder; D weld the coil on the container.

[0006] Wherein step A comprises the following steps again: a, strip-shaped lath is processed into wide and shallow circular arc shape; B, wide and shallow circular arc shape is processed into narrower and deeper circular arc shape, and this circular arc shape between the arc shape of step a and the final semicircle; c, processing the arc shape of step b into the final semicircle. Step C further includes the following steps: d. placing the container cylinder on the rotary tire frame; e. rotating the rotary tire frame to make the cylinder rotate, and wrap the rolled bent pipe on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com