Gas burner

a burner and gas technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of increased manufacturing cost, difficulty in controlling premix burners, large number of parts, etc., and achieve the effect of reducing the number of manufacturing processes and reducing the manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, the construction and operation of exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0026]FIG. 3 is a plan view showing a gas burner according to an embodiment of the present invention.

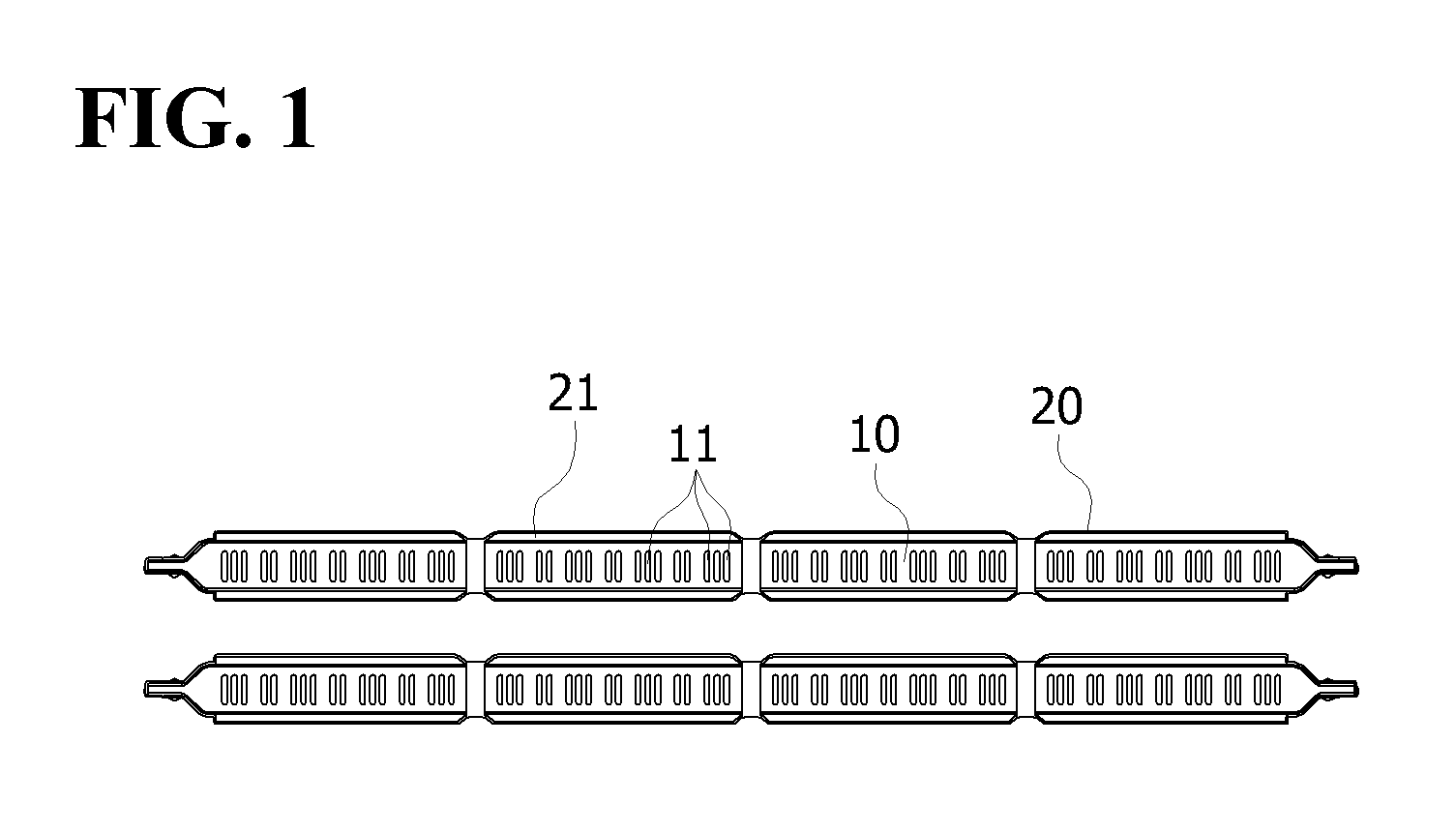

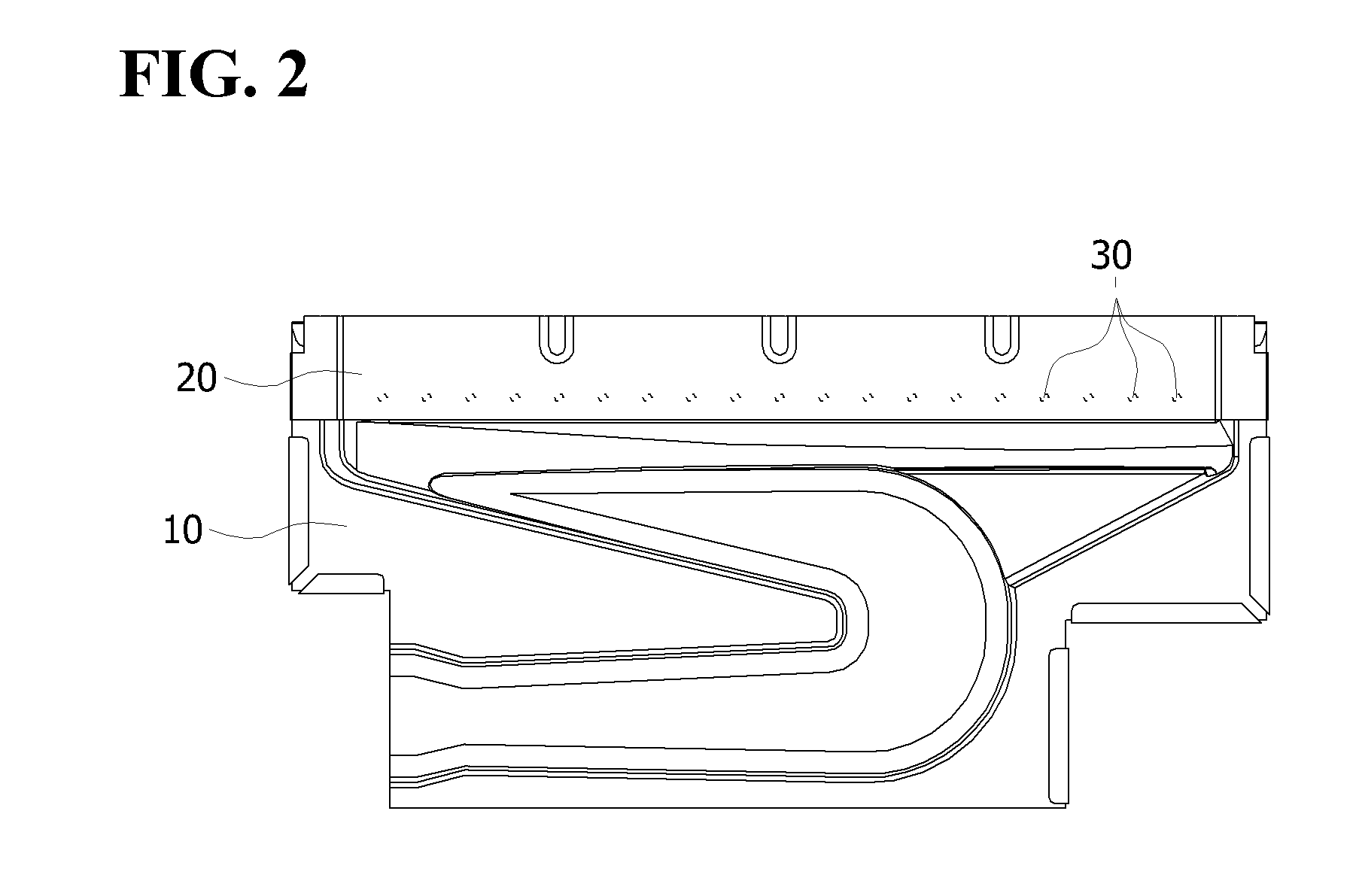

[0027]The gas burner 1 includes burner units 100 forming a flame, and first and second brackets 200a and 200b supporting opposite ends of the burner units 100.

[0028]Each burner unit 100 has a structure in which a plurality of burner units 110, 120 and 130 are disposed in a row at regular intervals.

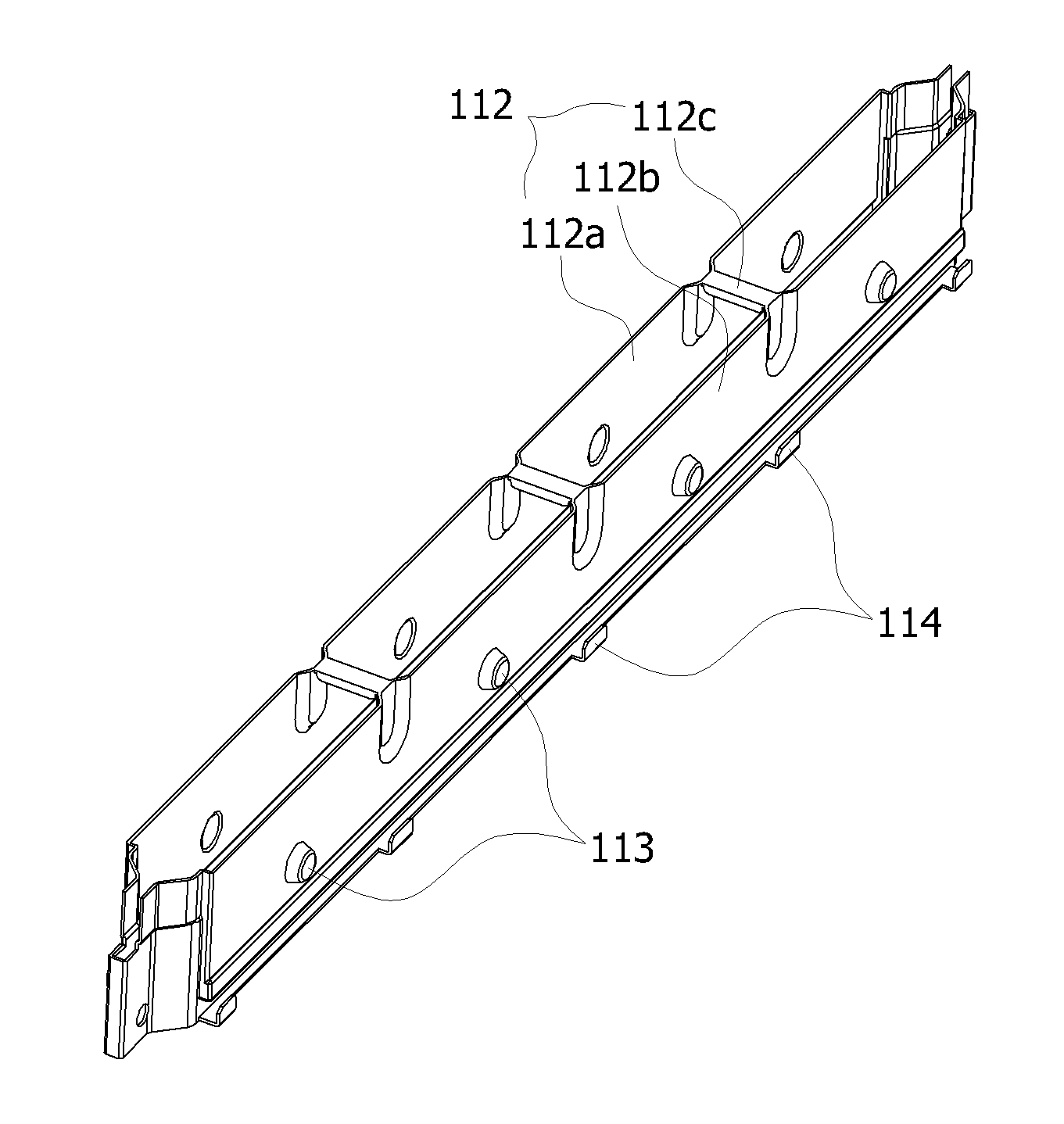

[0029]Opposite ends of each of the burner units 110, 120 and 130 have a shape in which a plurality of plates are bent so as to have a narrower width than a burner body, and are inserted into and fixed in grooves formed in the first and second brackets 200a and 200b.

[0030]FIG. 4 is a plan view showing a structure in which the burner units are of the present invention mutually supported.

[0031]Two of the burner units 110 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com