Antenna assembly and electronic device using same

An antenna assembly and electronic device technology, which is applied to antenna supports/installation devices, antenna parts, antennas, etc., can solve the problems of high manufacturing cost, wrinkling of the outer shell 91, increase in the cost of wireless communication terminals, etc., and saves welding. Process and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

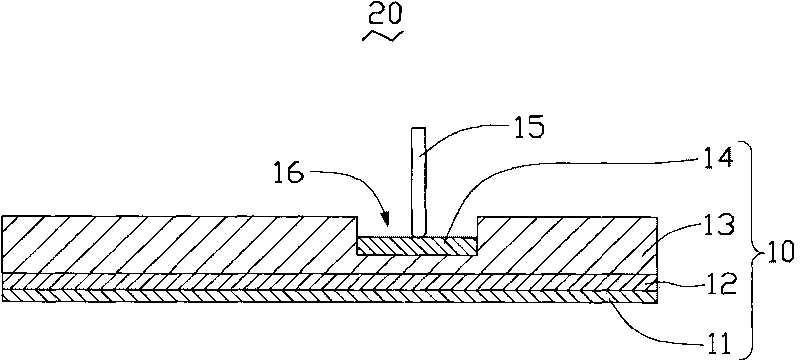

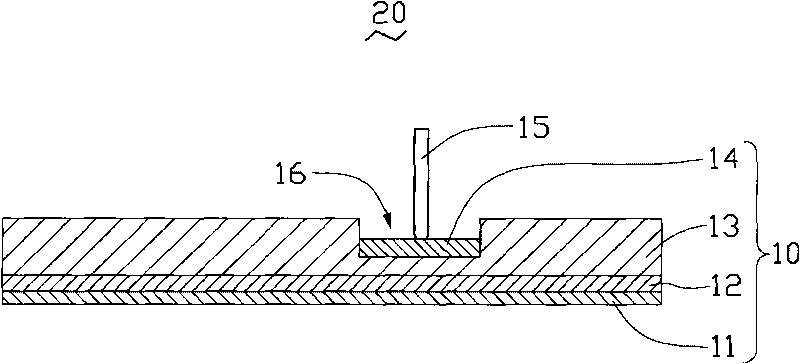

[0011] see figure 2 , the antenna assembly 10 of the preferred embodiment of the present invention includes a bearing layer 11 , an antenna layer 12 , a base layer 13 and a resonant coupling body 14 .

[0012] The carrier layer 11 can be a decorative resin film, such as polycarbonate, acrylonitrile-butadiene-styrene copolymer (Acrylonitrile-Butadiene-Styrene, ABS), polystyrene (PS, Polystyrene) or polyvinyl chloride ( PVC, Poly Vinyl Chloride) and other resin films.

[0013] The antenna layer 12 is a conductive pattern for receiving and sending radio signals. The antenna layer 12 may be a conductive ink layer formed on the carrying layer 11 by printing. The antenna layer 12 can also be a metal foil, such as copper foil, which can be attached to the carrier layer 11 by an adhesive. In addition, the antenna layer 12 can also be a metal coating layer formed as a conductive pattern, and the metal coating layer can be a vacuum coating layer or an electroplating layer.

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com