A construction method for a multi-layer large-span assembly integral space steel grid box structure factory building

A box-type structure and construction method technology, applied in industrial buildings, building structures, buildings, etc., can solve the problems of high labor intensity, large investment in engineering construction, poor comprehensive economic benefits, etc., and achieve the elimination of welding processes and structural top The effect of small displacement and convenient transportation of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

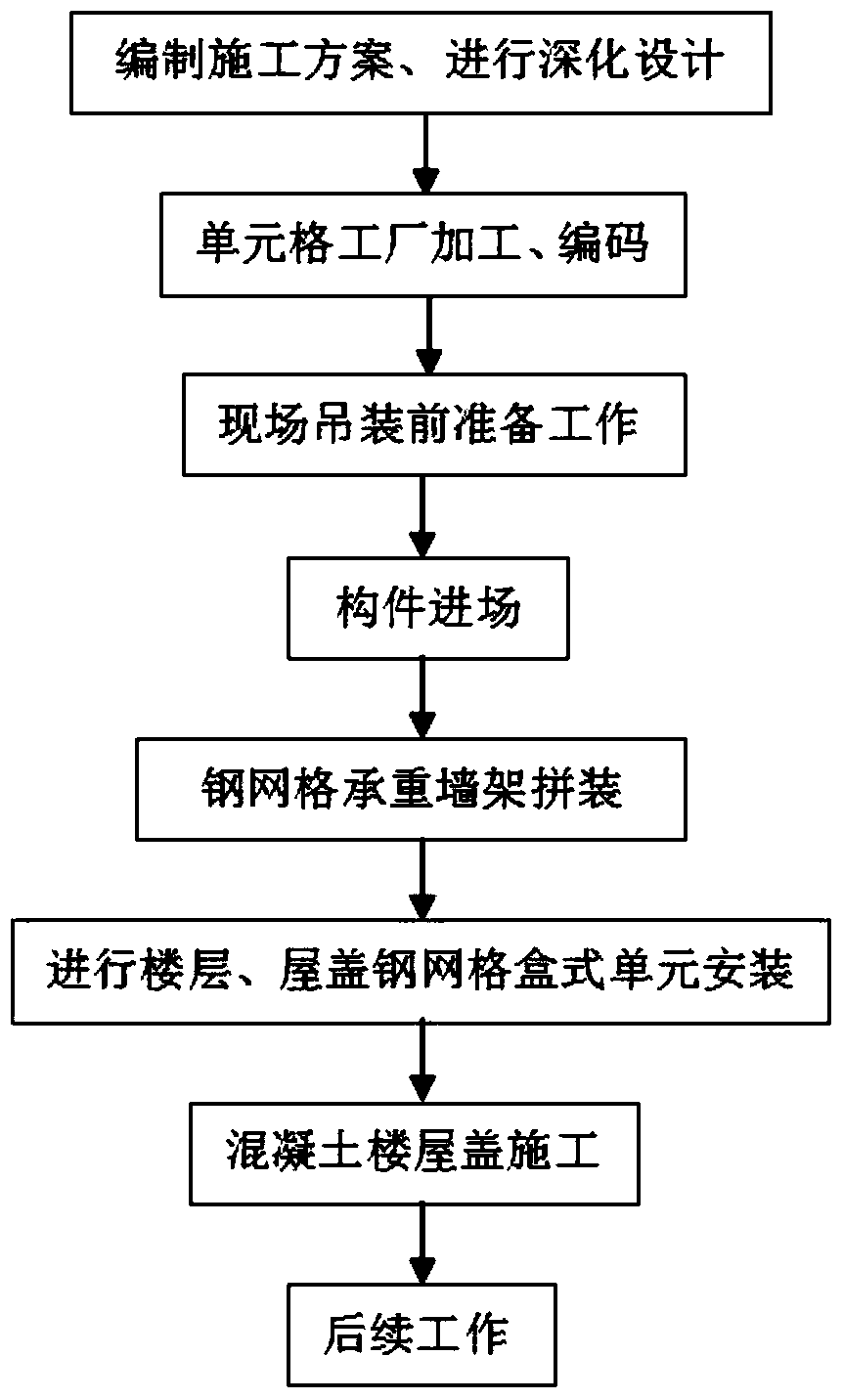

Method used

Image

Examples

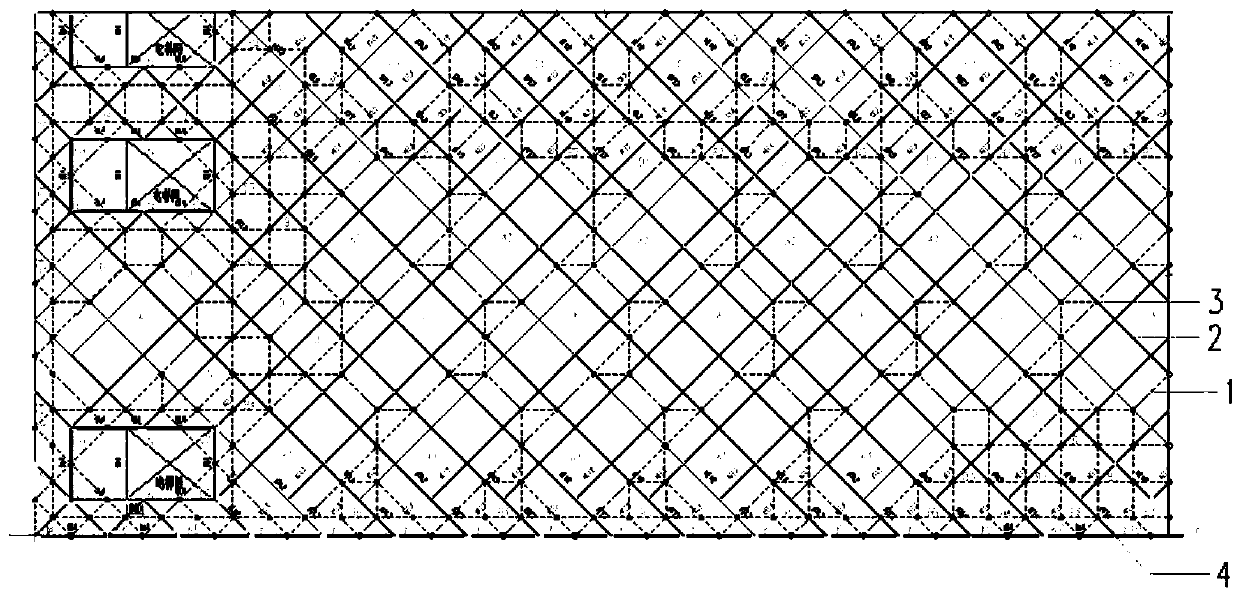

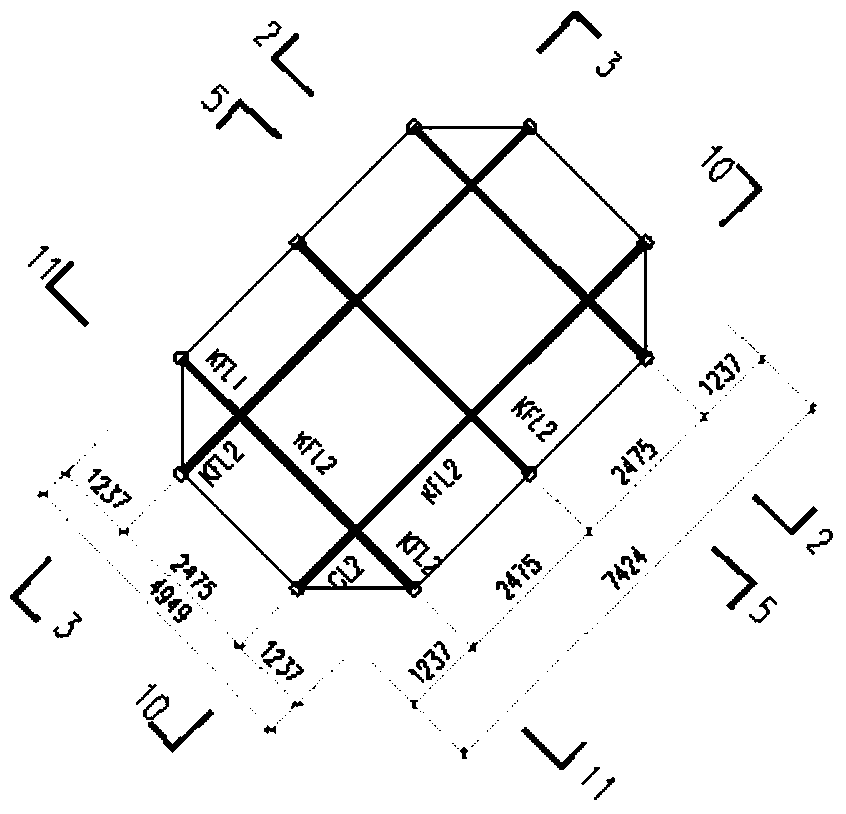

Embodiment 1

[0047] Example 1: China South Locomotive Group Guiyang New Industry Base Datian Shawen Industrial Park Project No. D103 Production Plant, with a construction area of 22627.68㎡, an orthogonal and obliquely assembled integral space steel grid multi-layer large-span box-type structure plant, with a width of 77m , the span is 21m×3+14m four-span, the axis length is 143.5m, the column spacing is 3.5m and 7.0m respectively, the number of building floors is 2, the height between floors is 7m, the building height is 14m, and the eaves height is 15.8m. Construction started in December 2013, basically completed in May 2014, installation of production process equipment began in June, and product production began in September; No. D104, comprehensive workshop of Datianshawen Industrial Park Project, Guiyang New Industrial Base, CSR Group. The construction area is 18,403.11㎡, and the vertical and oblique assembled integral space steel grid multi-layer large-span box-type structure factory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com