Combined knockout core structural investment pattern die bundling core

A core-pulling structure and combined technology, which is applied in the direction of cores, molds, and mold components, can solve problems that affect the consistency of shape, size and size of casting products, easy slag inclusion, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

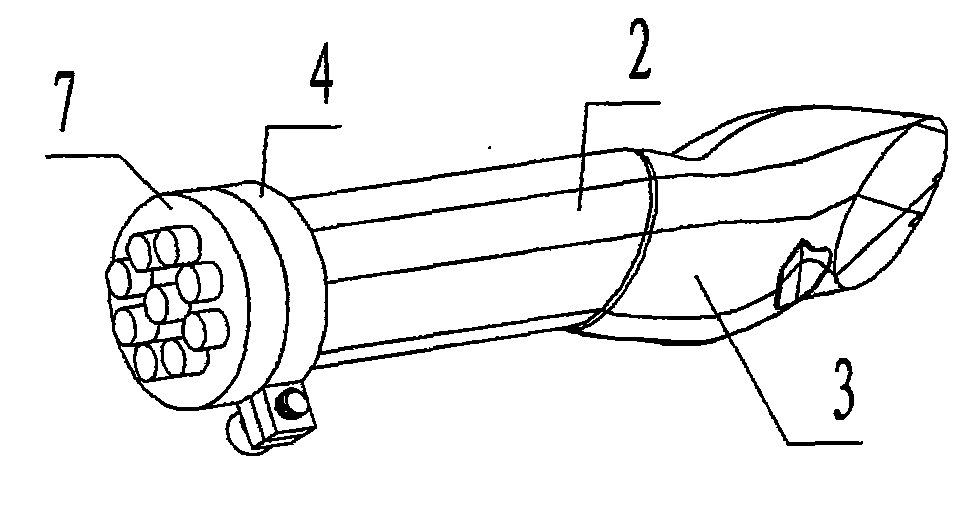

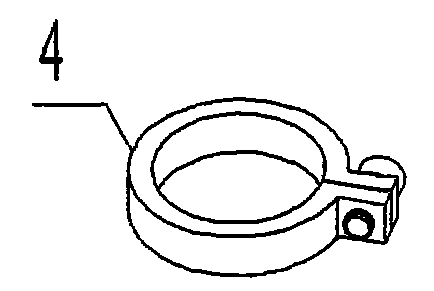

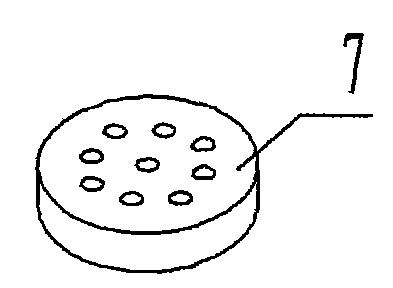

[0020] refer to Figure 1 to Figure 7 , a combined core-pulling structure investment mold cluster core of the present invention includes a positioning mandrel 1, a pumping flap 2, a flap 3, a clamp 4, and an end seat 7, wherein: the The positioning mandrel 1 is in the core divided by the "well" shape, located at the center of the core axis, the section is a rectangular petal strip, and each of the four surface centers is provided with a raised guide rail 6 along the axial direction. There is a fixed blind screw hole in the center of the end of the strip; the pumping flap 2 is a core divided by a "well" shape, located on the four sides of the positioning mandrel 1, and has three cutting surfaces and a flap The center of the contact surface with the positioning mandrel 1 is provided with a recessed guide groove 5 along the axis direction, and the center of the tail end of the flap is provided with a fixed blind screw hole; Among the divided cores, the flaps with two cutting sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com