Lighting stick with LBD wafer

A technology of light-emitting diodes and light-emitting sticks, applied in the field of light-emitting sticks, can solve the problems of adverse effects of light-emitting sticks, small heat dissipation area, and poor heat dissipation effect, and achieve the effects of facilitating large-scale production, increasing heat dissipation area, and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Label in the figure

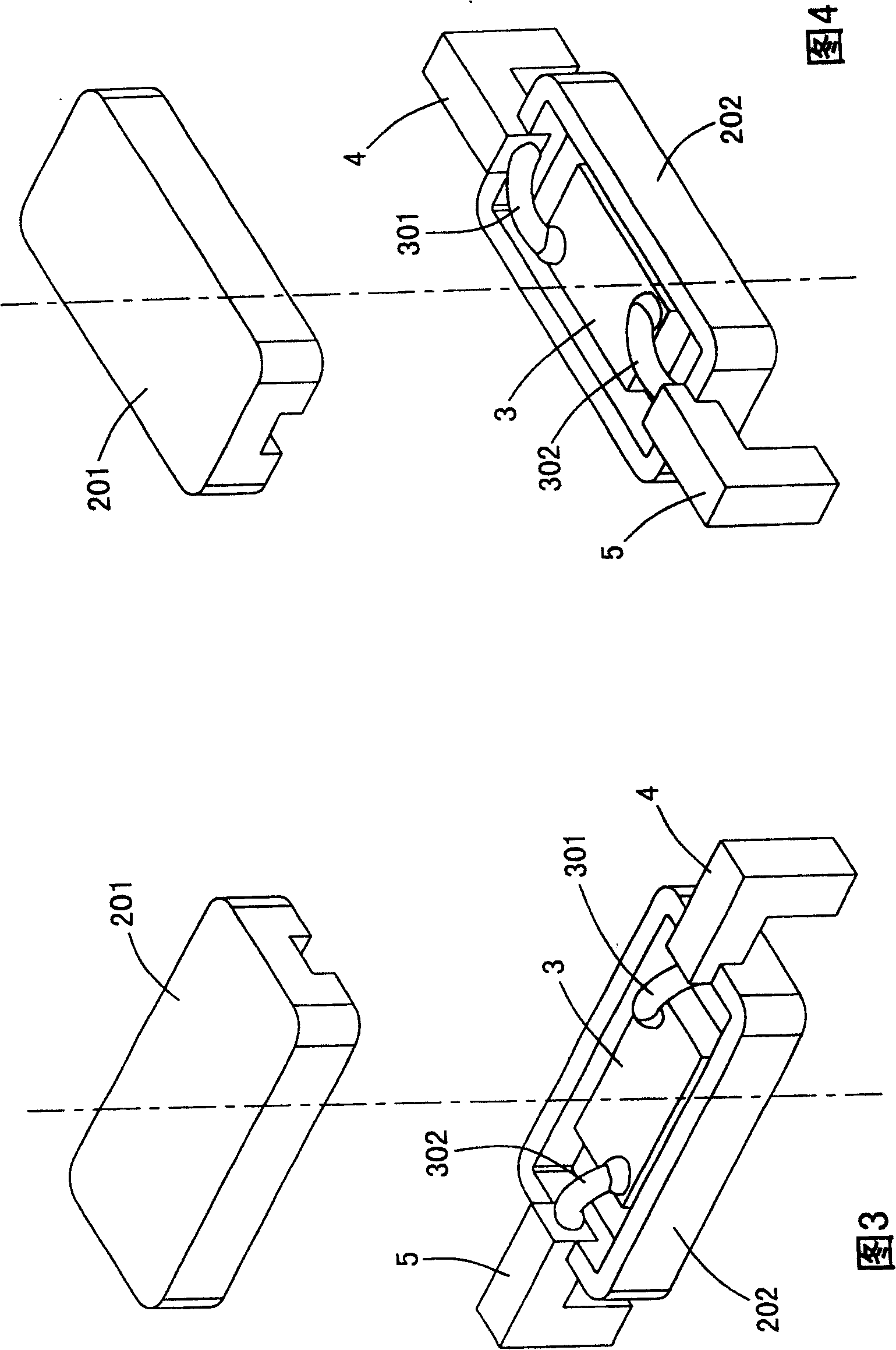

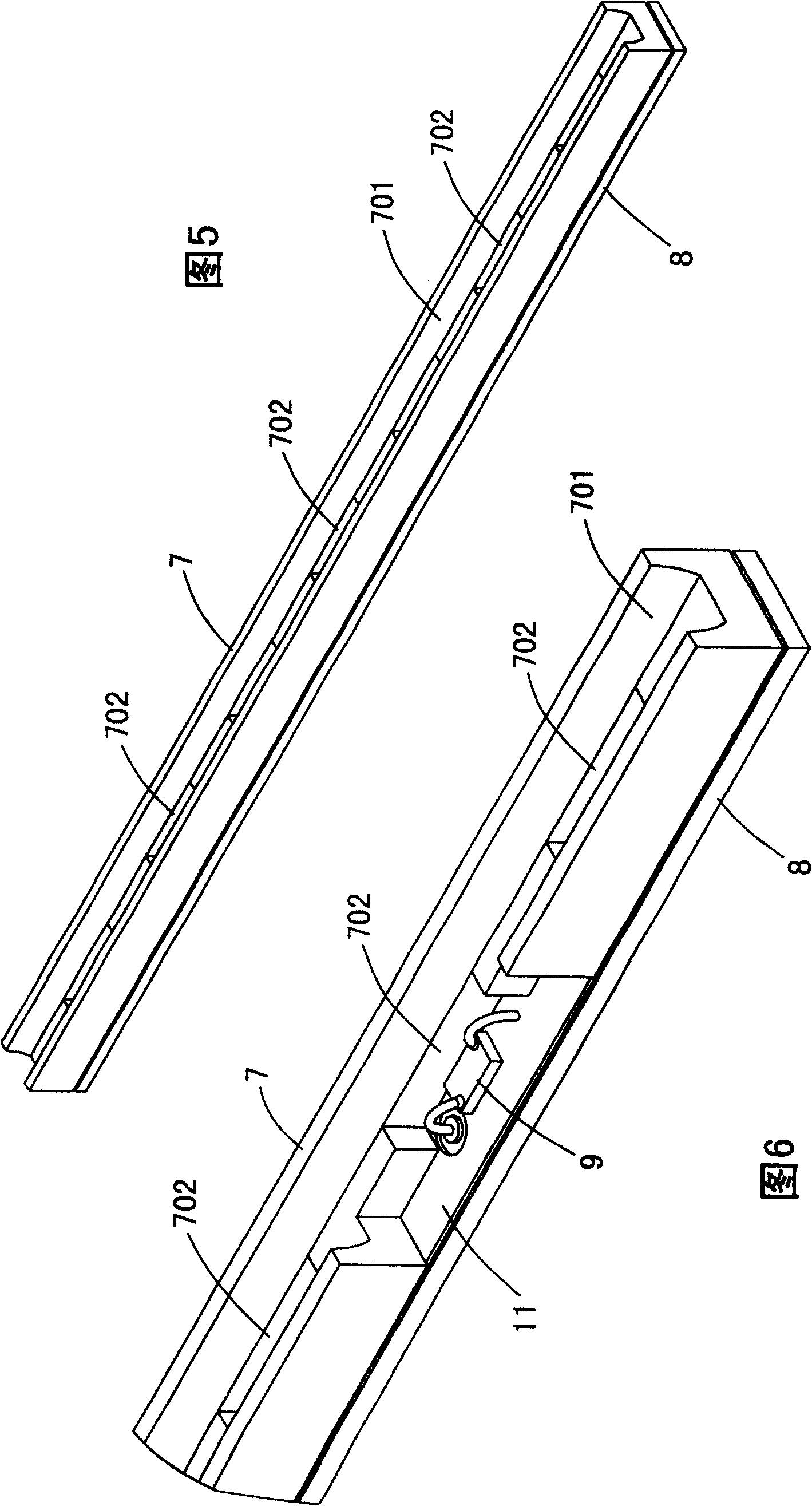

[0038] 1. Circuit board 2. Light-emitting diode 201. Top cover 202. Base 3. Light-emitting diode chip 301. Negative terminal soldering wire 302. Positive terminal soldering wire 4. Pin 401. Tin solder joint 5. Pin 501. Tin solder joint 6. Aluminum substrate 7. Frame 701. Groove 702. Vertical hole 8. Circuit board 9. Light-emitting diode chip 901. Negative terminal welding wire 902. Positive terminal welding wire 11. Negative electrode welding plate 111. Through hole 12. Positive electrode welding Plate 13. Transparent Silicone

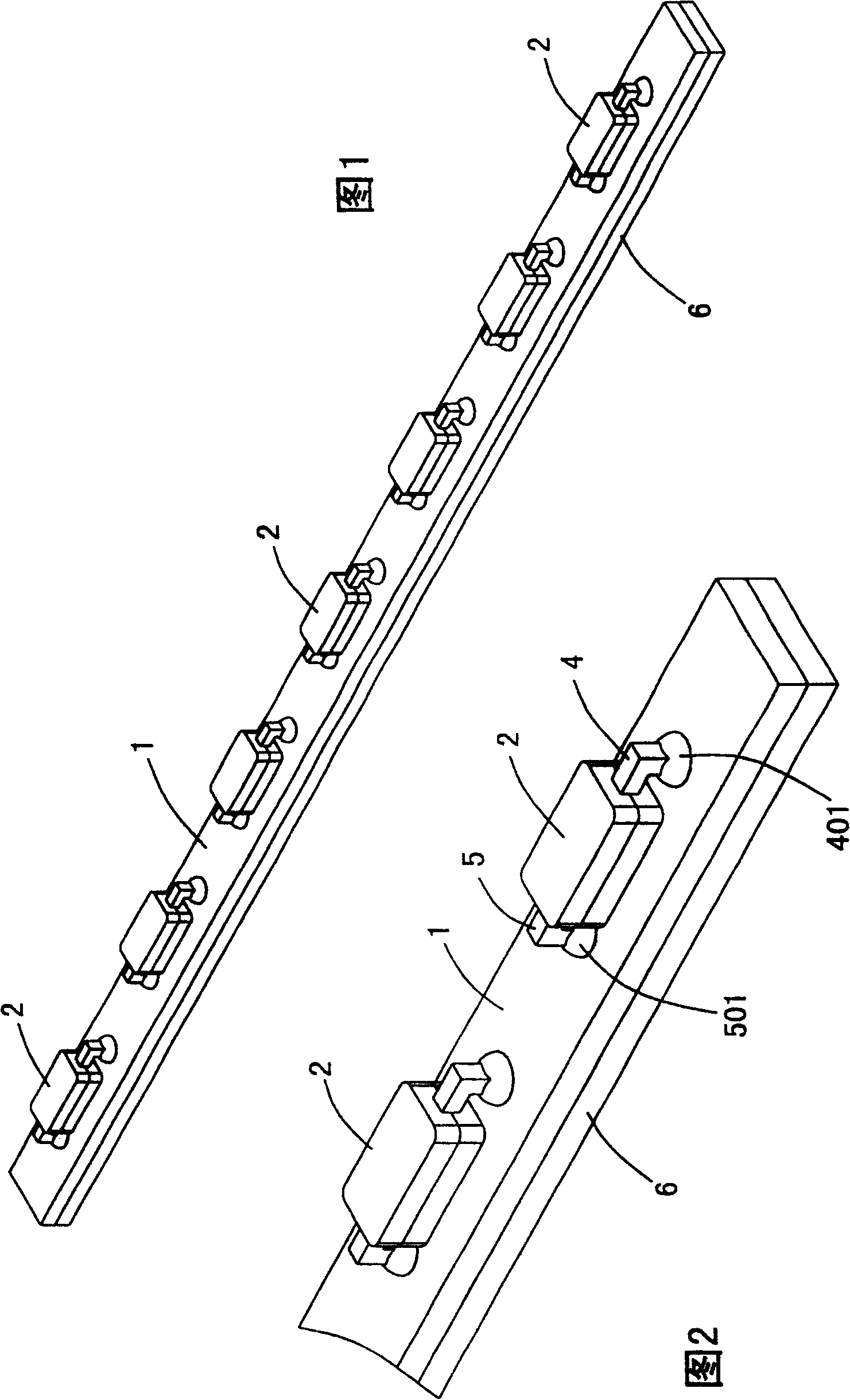

[0039] In order to facilitate a better understanding of the essential features of the present invention, firstly introduce the structure of the existing light stick. Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, the structure of the existing luminous stick is: a plurality of light-emitting diodes 2 are arranged at intervals on the strip-shaped circuit board 1, and each light-emitting diode 2 is composed of a housing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com