Multilayer large-span assembling integral type space steel grid building structure and manufacturing method

A technology of building structure and grid structure, applied in building construction, construction, building material processing, etc., can solve the problems of unwillingness to build cost, difficult to guarantee project quality, high-rise and multi-storey buildings, etc.

Inactive Publication Date: 2012-10-03

HUNAN UNIV +4

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Over the past 30 years of reform and opening up, in the construction of industrial plants in various provinces and cities, more than 90% are single-story industrial workshops. The main reasons are as follows: First, it is manufactured according to the traditional steel frame structure system, due to the large amount of steel used and the high cost (It is more than twice that of a single-story steel structure); secondly, due to the low unit price of land in the early stage, people are unwilling to build multi-storey buildings with high costs

At present, in many areas of our country, especially the economically developed areas, in order to ensure 1.8 billion mu of arable land and protect the ecological environment, except for heavy industry workshops, single-story buildings are not allowed. This is the general trend of economic construction. Under this condition, due to the traditional The steel frame structure has a large amount of steel per unit area, high cost, and its beams and columns are large and heavy. However, the construction of the traditional steel frame structure is carried out on site, and a large number of welding operations are required at high altitude. Not only The quality of the project is difficult to guarantee, and its construction is still very difficult, so the existing multi-layer steel frame structure can no longer meet the actual needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

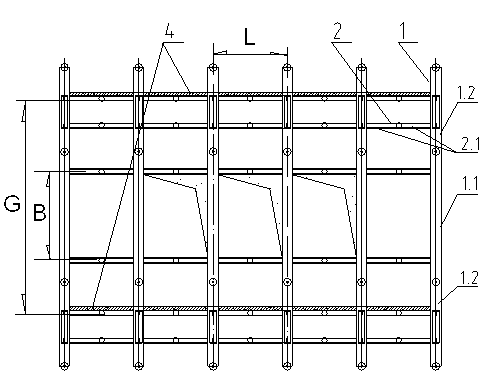

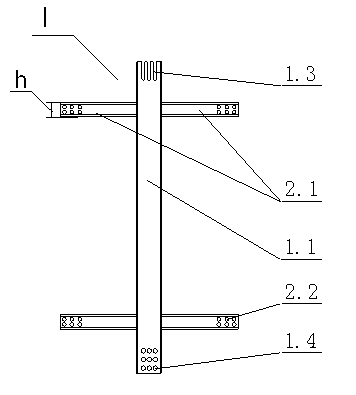

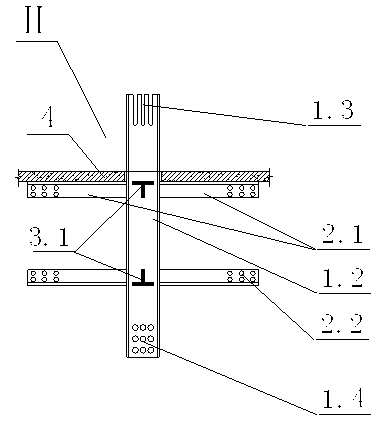

The invention discloses a multilayer large-span assembling integral type space steel grid building structure and a manufacturing method. The multilayer large-span assembling integral type space steel grid building structure is formed by adopting a steel grid type bearing outer wall structure and an assembling integral plated type or curved surface type steel hollow grid structure as a floor cover or a house cover structure to be assembled; the steel grid type bearing outer wall structure is formed by connecting a combined upright columns manufactured by rectangular steel tubes and combined transverse beams manufactured by H-shaped steel or T-shaped steel; the rectangular shape of the upright column is 200-300mm in height or width; the wall thickness of the upright column is 4-10mm; the shape height of the H-shaped steel or T-shaped steel of the transverse beam is 100-200mm; the center distance between every two adjacent upright columns is 1500-4000mm; and five transverse beams are connected in a column net structure within each height range and between two adjacent upright columns. The multilayer large-span assembling integral type space steel grid building structure has the advantages of being light in weight, high in strength, easy to construct, good in quality and the like.

Description

technical field The invention relates to a multi-layer large-span assembled integral space steel grid building structure and a manufacturing method thereof, belonging to the technical field of steel structure building frame manufacturing and construction. Background technique With the rapid increase of my country's steel production, the application of steel structures in the field of construction engineering is increasing, such as multi-storey (2-4 storeys) long-span (18m-36m) public and industrial buildings, and high-rise and super high-rise large bays, large For column grid residential and office buildings, these steel structure systems generally use rectangular steel pipes and H-shaped steel to form a steel frame structure. For the steel frame structure of a four-story industrial workshop with a span of 18m and a floor height of 5.2m, rectangular steel pipes with specifications of 600×600×25 (length×width×thickness) or 500×500×25 are generally used as columns , the center...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/342E04G21/14

Inventor 马克俭徐向东胡岚曾勇朱方正肖建春周观根周家干张华刚程志敏张晓楠段渝忠

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com