Corrugated plate wave crest distance measuring method

A measurement method, corrugated plate technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of inaccurate measurement and non-adjustment, and achieve the effect of improving the simplicity and accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

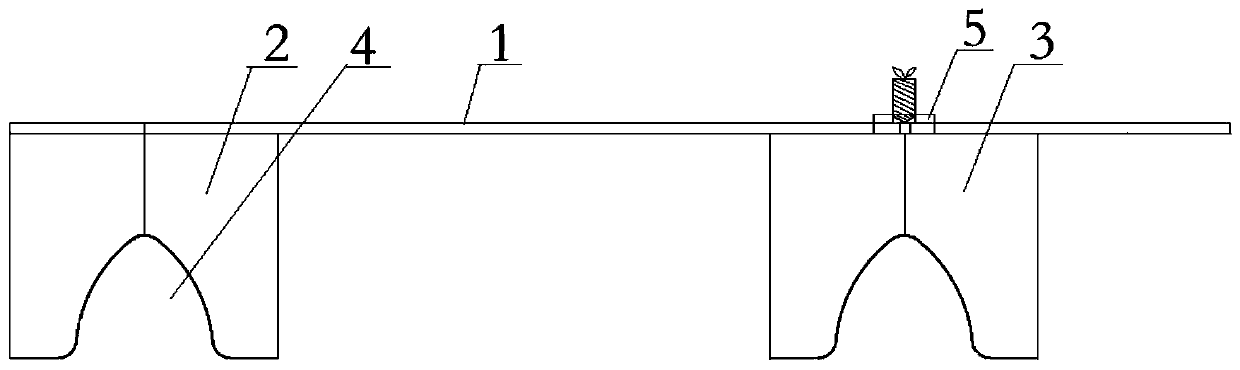

[0027] Such as figure 1 and figure 2 As shown, this embodiment provides a corrugated board wave crest distance measuring tool, which includes a measuring rule 1 and a corrugated clamp used in combination, and the corrugated clamps are arranged in multiple groups according to the specifications of the corrugated board. The corrugated card block includes a fixed corrugated card block 2 and a movable corrugated card block 3. Both sides of the fixed corrugated card block 2 and the movable corrugated card block 3 are provided with a corrugated card slot 4, the corrugated card slot 4 and the corrugated board Matching with the corrugation on the corrugated board. The top of the corrugated slot 4 on the fixed corrugated block 2 and the movable corrugated block 3 are both provided with a reading line in the opposite direction of the opening of the corrugated slot 4 , The reading line is perpendicular to the length direction of the measuring ruler 1, the fixed corrugated clamp 2 is fixed...

Embodiment 2

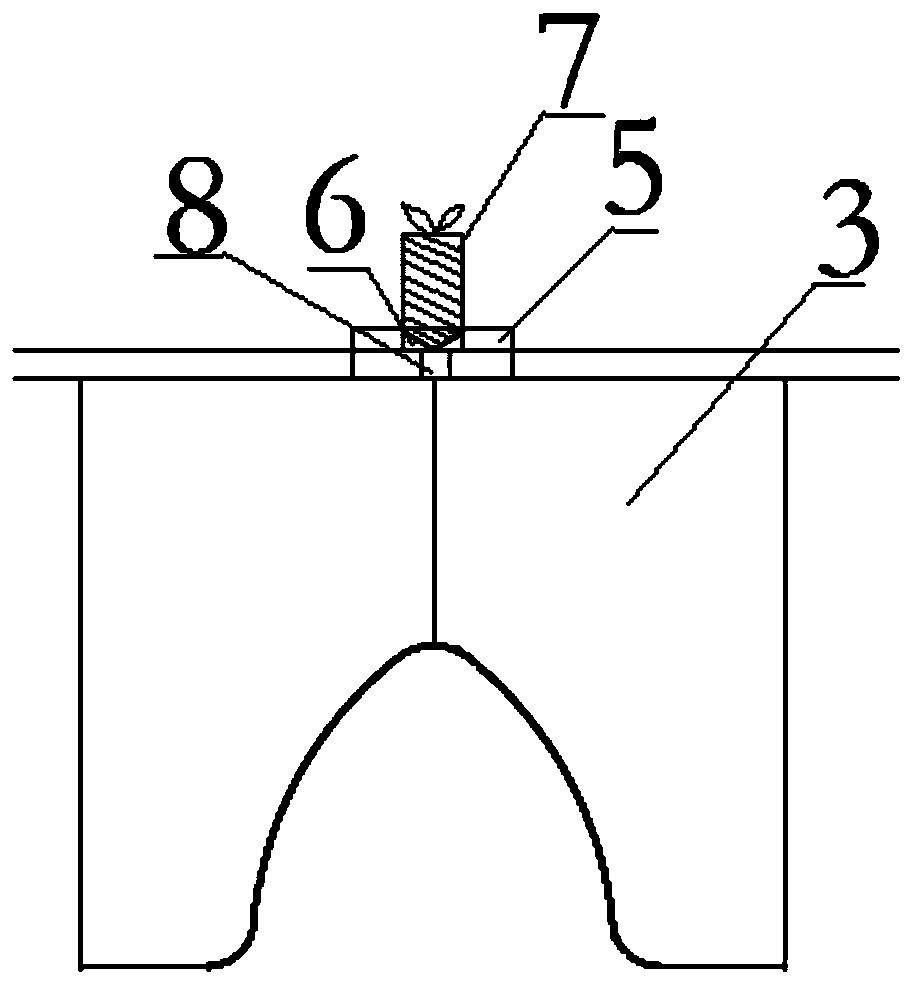

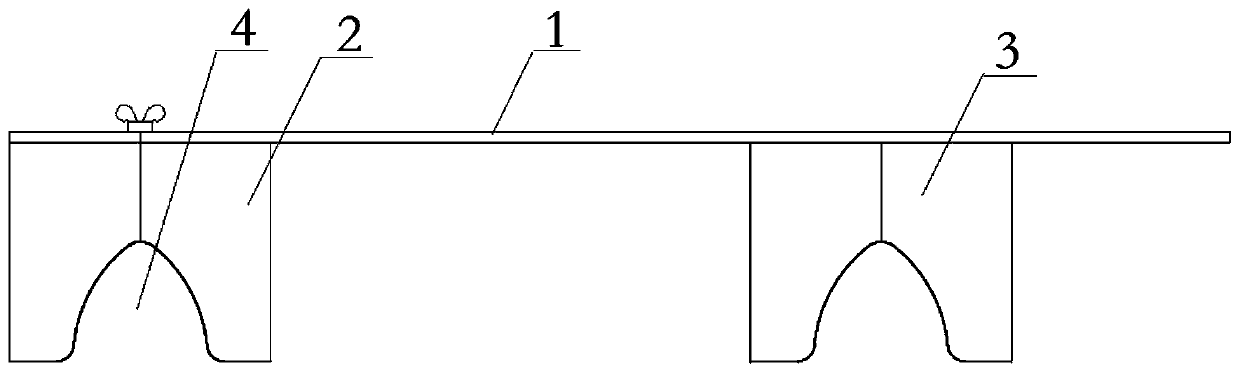

[0030] Such as Figure 3-Figure 5 As shown, this embodiment provides a corrugated board wave crest distance measuring tool, which includes a measuring rule 1 and a corrugated clamp used in combination, and the corrugated clamps are arranged in multiple groups according to the specifications of the corrugated board. The corrugated card block includes a fixed corrugated card block 2 and a movable corrugated card block 3. Both sides of the fixed corrugated card block 2 and the movable corrugated card block 3 are provided with a corrugated card slot 4, the corrugated card slot 4 and the corrugated board Matching with the corrugation on the corrugated board. The top of the corrugated slot 4 on the fixed corrugated block 2 and the movable corrugated block 3 are both provided with a reading line in the opposite direction of the opening of the corrugated slot 4 , The reading line is perpendicular to the length direction of the measuring ruler 1, the fixed corrugated clamp 2 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com