Special-shaped cavity sampling structure

A special-shaped cavity and chamber technology, applied in sampling devices and other directions, can solve problems such as blockage and lumen stenosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

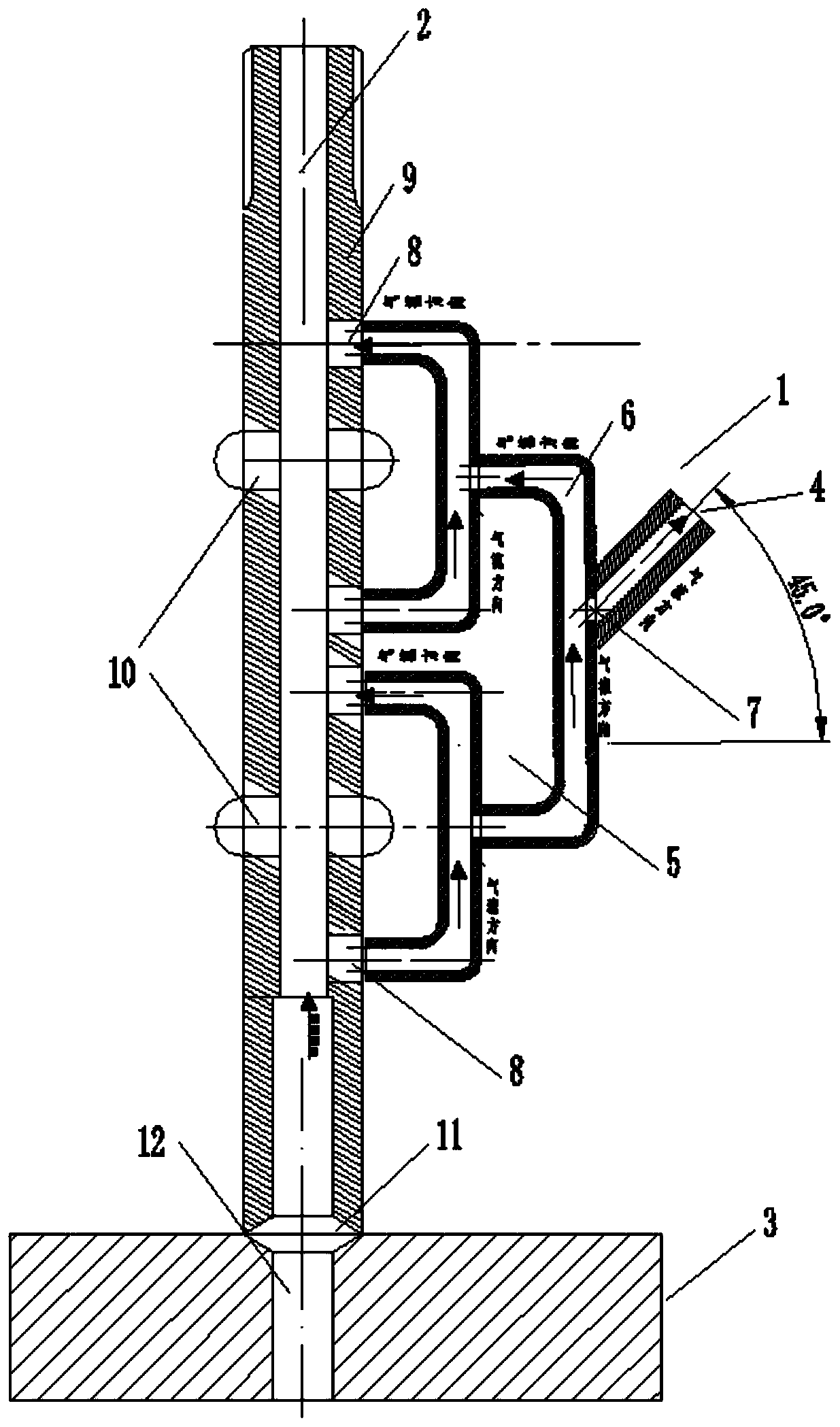

[0021] The invention belongs to the measurement and testing category in the field of industrial measurement, is a measurement and testing technology, relates to a special-shaped chamber sampling structure and its use method, and relates to the measurement of real-time pressure, temperature and other physical quantity parameters under complex working conditions and environmental conditions. The content includes the sampling structure and usage method of special-shaped chambers. It is characterized by the use of new structural design methods to solve the problem of narrowing and blockage of the measurement channel due to dust and debris deposition under complex working conditions and environmental conditions, which in turn leads to physical parameters of the medium working condition. The problem that it is difficult to measure accurately, the invention fills up the deficiencies in the prior art.

[0022] The present invention is a collection of technical means for the purpose of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com