Quality-related fault online monitoring method for efficiently updating model under time-varying system

A quality-related, time-varying system technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as inability to monitor quality-related faults, high computational complexity of model update, and low update efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

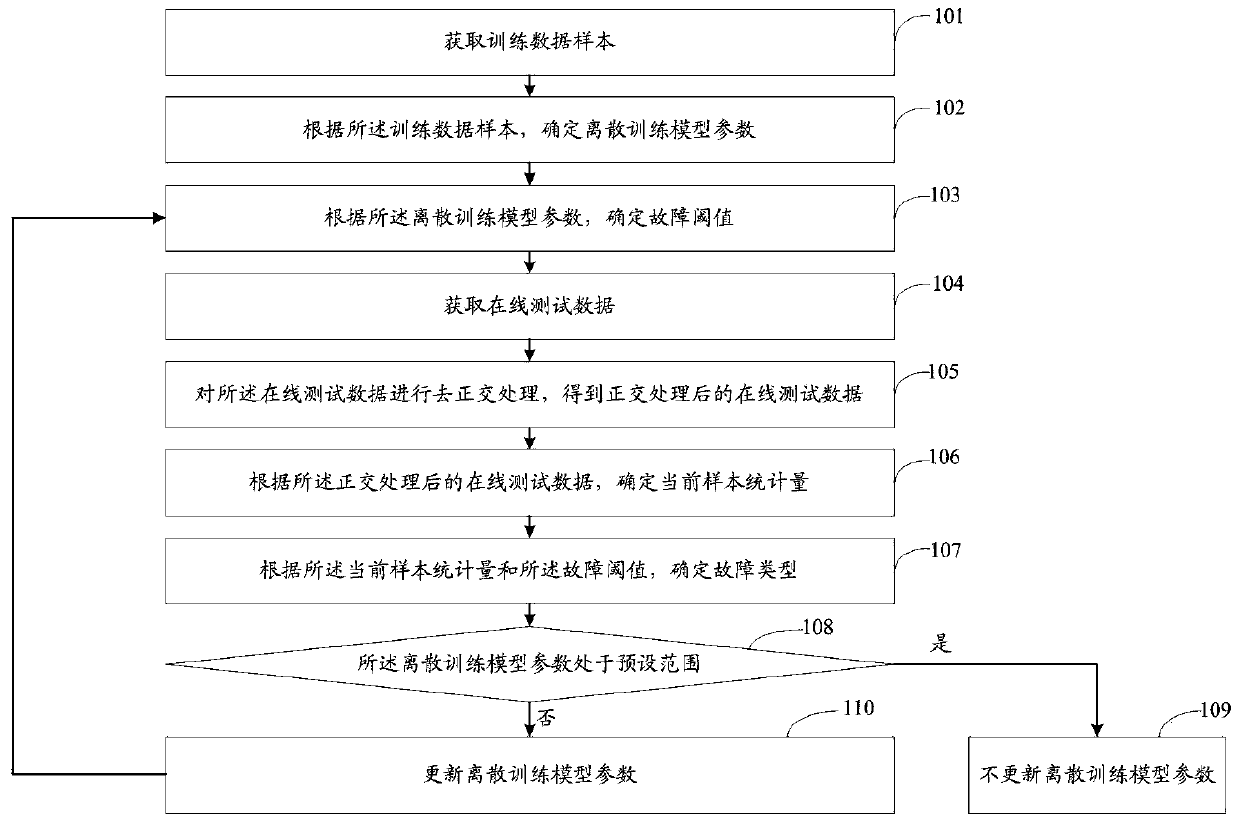

Method used

Image

Examples

Embodiment

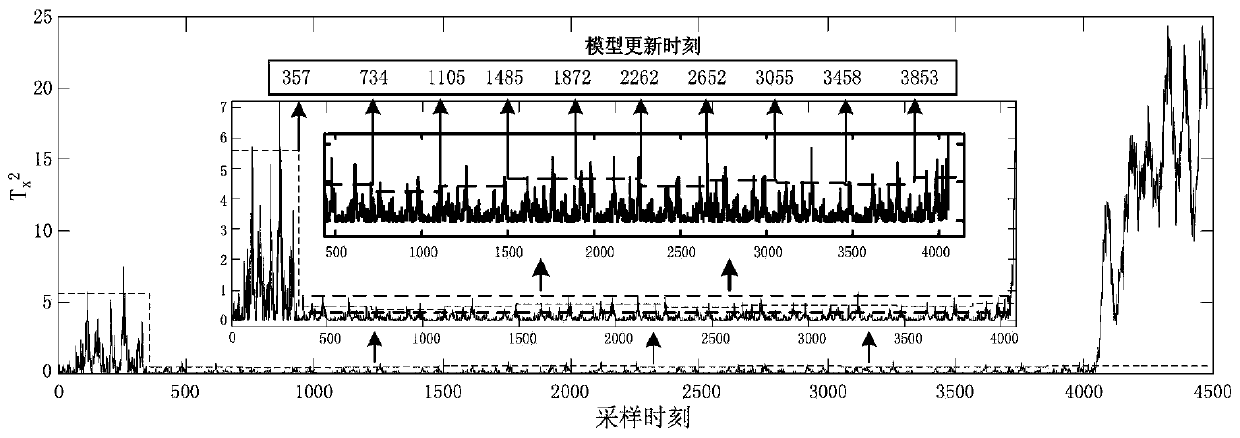

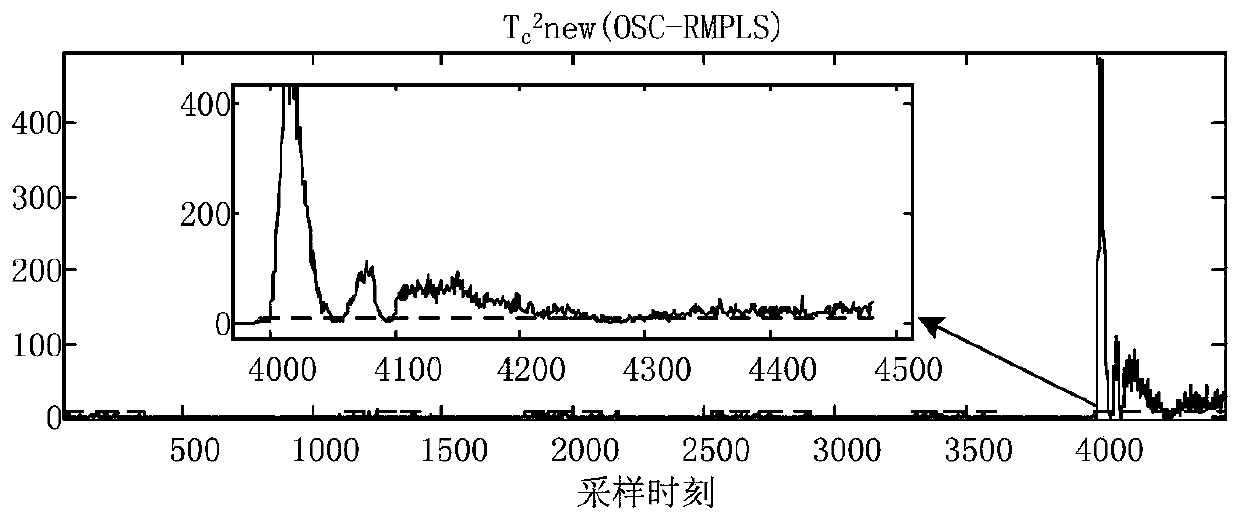

[0129] The method proposed by the present invention will be verified below through the data collected in the Tennessee-Eastman (TEP) experiment. TEP is a small-scale industrial process developed by Eastman Chemical Company Downs and Vogel in 1993. The entire process consists of five operating units, including chemical reactors, condensers, compressors, vapor / liquid separators, and separators.

[0130] TEP contains eight components: A, B, C, D, E, F, G and H, where gaseous substances A, C, D and E and inert substance B are reactants, G and H are reaction products, and F is reaction by-products. In the reactor, 4 reactions are carried out simultaneously with the assistance of the catalyst:

[0131]

[0132] Table 1 is 12 control variables (XMV), Table 2 is 41 measurement variables (XMEAS); Table 3 is 15 known faults (IDV). Table 1-Table 3 are as follows:

[0133] Table 1 12 control variables (XMV)

[0134]

[0135] Table 2 41 measurement variables (XMEAS)

[0136] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap