Transformer mounting structure convenient to mount and mounting method thereof

An installation structure and transformer technology, applied in the field of transformers, can solve problems such as low accuracy and affecting the installation quality of transformers, and achieve the effect of preventing inconvenient rotation and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

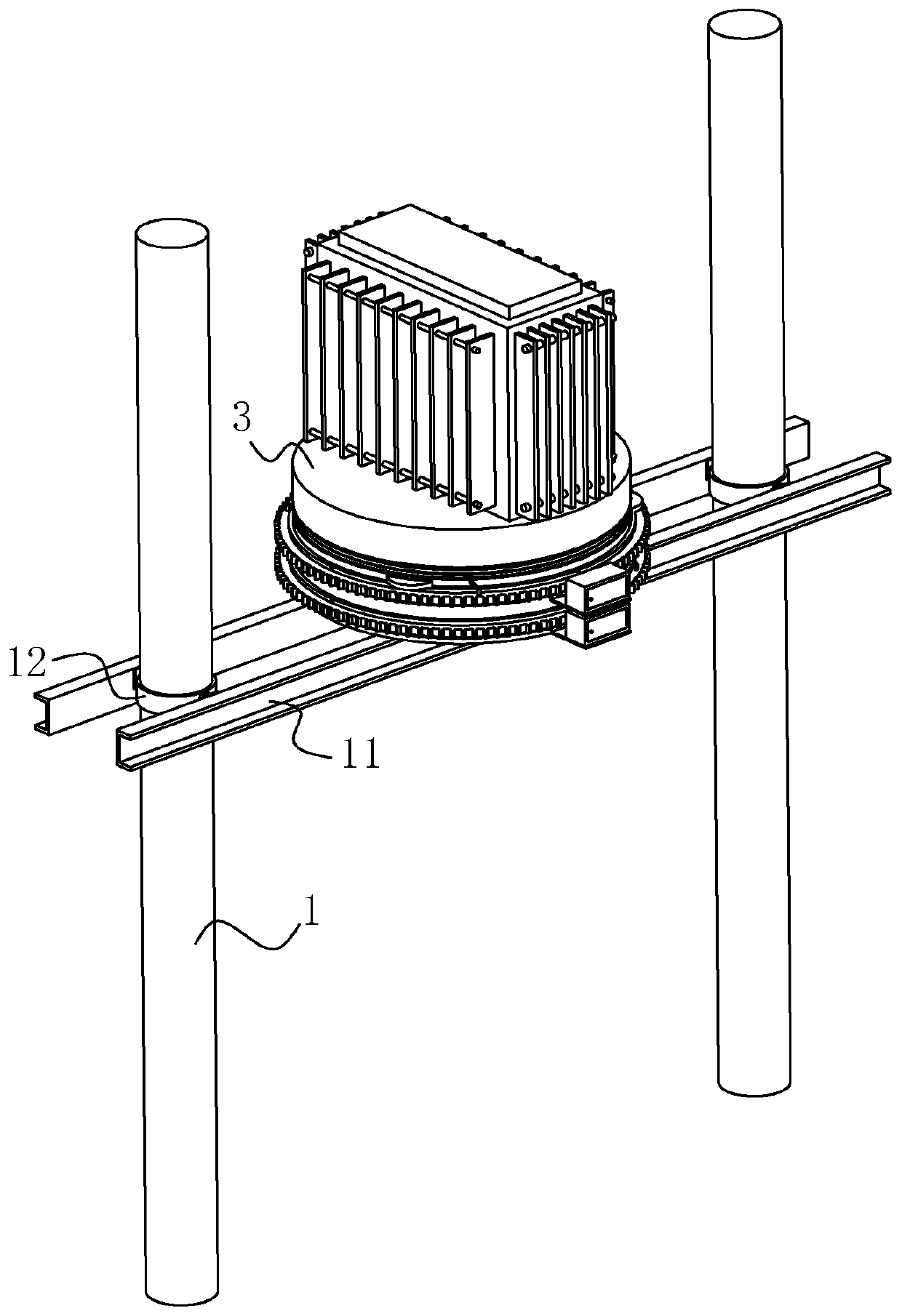

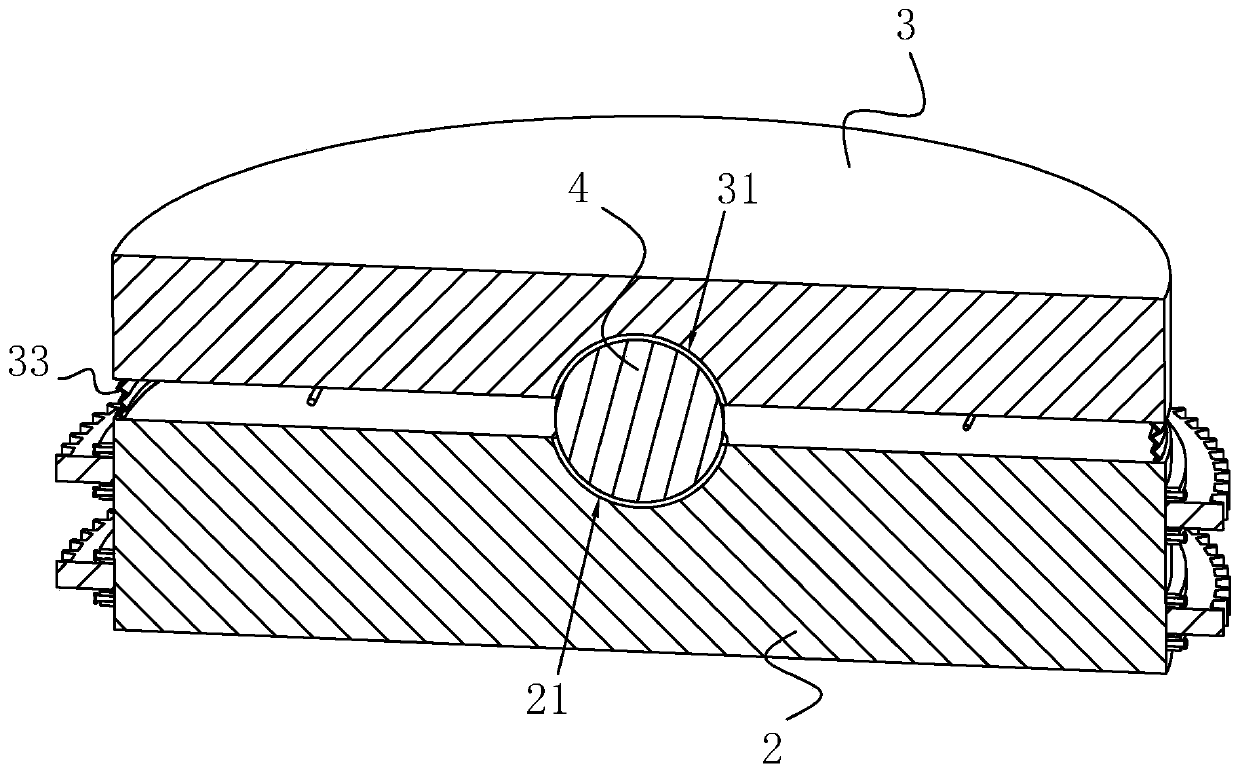

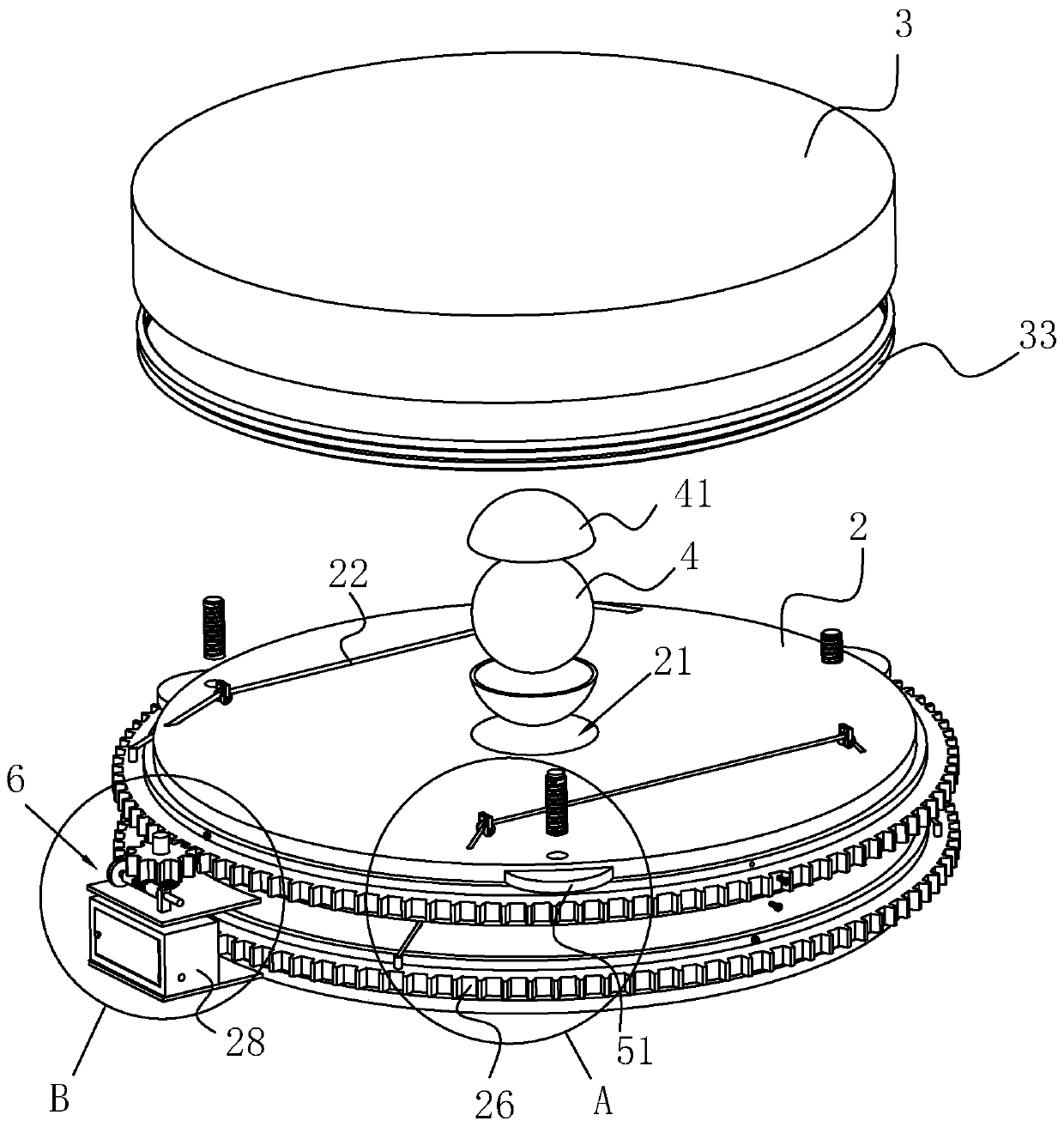

[0046] Such as figure 1 , 2 As shown, an easy-to-install transformer installation structure includes a base 2, a movable seat 3 and an adjusting ball 4. The adjusting ball 4 is a steel ball, and the cross section of the base 2 is circular. The top wall of the base 2 is provided with an arc-shaped first groove 21, the bottom wall of the movable seat 3 is provided with a second groove 31, and the adjusting ball 4 is rotatably embedded in the first groove 21 and the second groove 31. . The center of gravity of the movable seat 3 is on the same vertical line as the center of gravity of the adjusting ball 4; Leave space for the deflection of the movable seat 3 .

[0047] Such as figure 2 , 3 As shown, the first groove 21 and the second groove 31 are embedded with a polytetrafluoroethylene plate 41 bonded to the adjustment ball 4, the polytetrafluoroethylene plate 41 is an arc-shaped structure, and the polytetrafluoroethylene plate 41 adhere to the first groove 21 and the sec...

Embodiment 2

[0061] A transformer installation method for easy installation, comprising the following steps:

[0062] S1. Install the supporting frame 11, and fix the supporting frame 11 on the electric pole 1 through the hoop 12; the supporting frame 11 includes two channel steels.

[0063] S2. Lift the base 2 and the movable seat 3 together on the support frame 11, and then fix the base 2 on the support frame 11 by bolts.

[0064] S3. After the movable seat 3 is kept in balance, drive the support rod 5 to move upward through the adjustment member until the support rod 5 just abuts against the bottom wall of the movable seat 3, and after each support rod 5 abuts with the movable seat 3 , the position of the movable seat 3 is fixed by the fixture.

[0065] S4. Hoist the transformer on the movable seat 3, and fix it with the movable seat 3 through bolts.

[0066] After the base 2 is hoisted on the support frame 11, the base 2 is fixed on the support frame 11 by bolts. If the support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com