Flattening machine for PVC film processing

A technology of PVC film and flattening machine, applied in the field of flattening machine, can solve the problem of PVC film damage and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

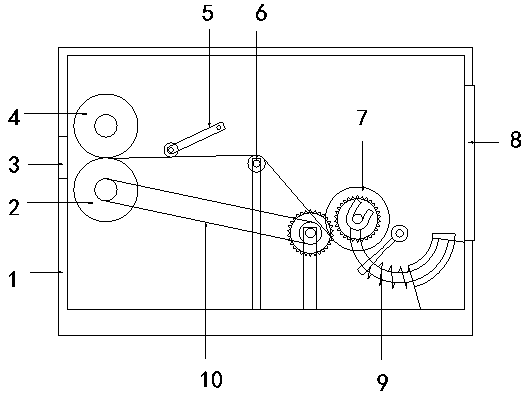

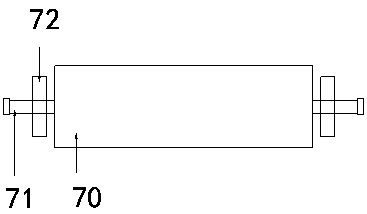

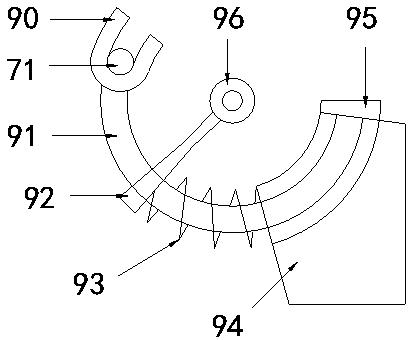

[0027] see Figure 1-4 , the present invention provides a technical solution for flattening machine used in PVC film processing: its structure includes a box body 1, a lower nip roller 2, an outlet 3, an upper nip roller 4, a tensioning structure 5, a support wheel 6, and an unwinding roller 7 , box door 8, booster structure 9, transmission device 10, the upper left side of the box body 1 is provided with an outlet 3, the upper nip roller 4 is installed inside the box body 1 and arranged on the side of the outlet 3, the upper nip roller The lower nip roller 2 is arranged below the roller 4, the support wheel 6 is arranged in the middle of the box door 8, the unwinding roller 7 is arranged on the right side of the box body 1, and the box body 1 right side is provided with a box door 8, so The booster structure 9 is provided with 2 and is respectively arranged on the two ends of the unwinding roller 7, and the two ends of the unwinding roller 7 are respectively installed on the ...

Embodiment 2

[0036] see Figure 1-5 , the present invention provides a technical solution for flattening machine used in PVC film processing: its structure includes a box body 1, a lower nip roller 2, an outlet 3, an upper nip roller 4, a tensioning structure 5, a support wheel 6, and an unwinding roller 7 , box door 8, booster structure 9, transmission device 10, the upper left side of the box body 1 is provided with an outlet 3, the upper nip roller 4 is installed inside the box body 1 and arranged on the side of the outlet 3, the upper nip roller The lower nip roller 2 is arranged below the roller 4, the support wheel 6 is arranged in the middle of the box door 8, the unwinding roller 7 is arranged on the right side of the box body 1, and the box body 1 right side is provided with a box door 8, so The booster structure 9 is provided with 2 and is respectively arranged on the two ends of the unwinding roller 7, and the two ends of the unwinding roller 7 are respectively installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com