Feeding device of production line

A production line and raw material technology, applied in the field of production line feeding devices, can solve problems such as low degree of mechanization, and achieve the effects of convenient operation, improved production work efficiency, and convenient grasping and releasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

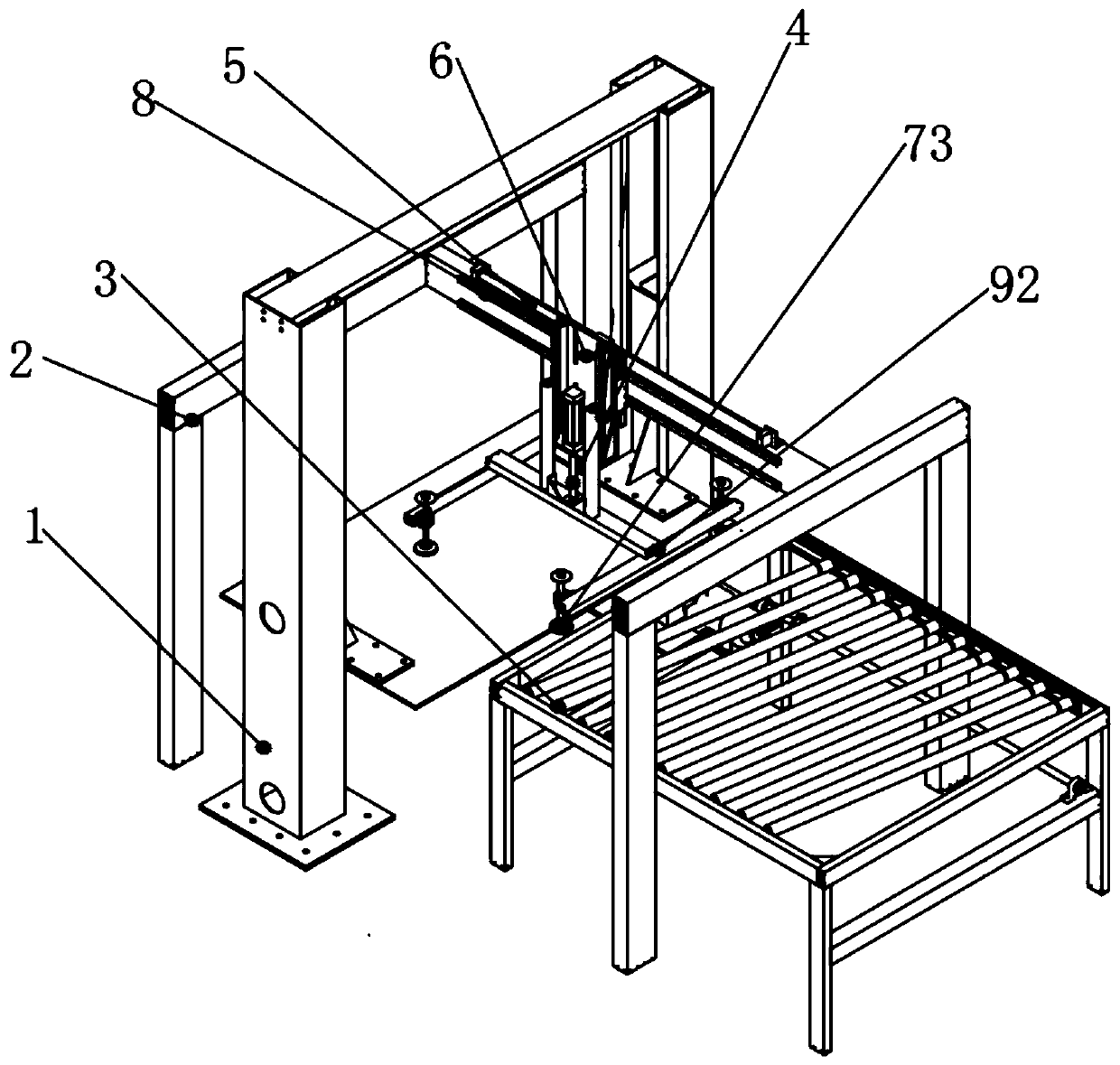

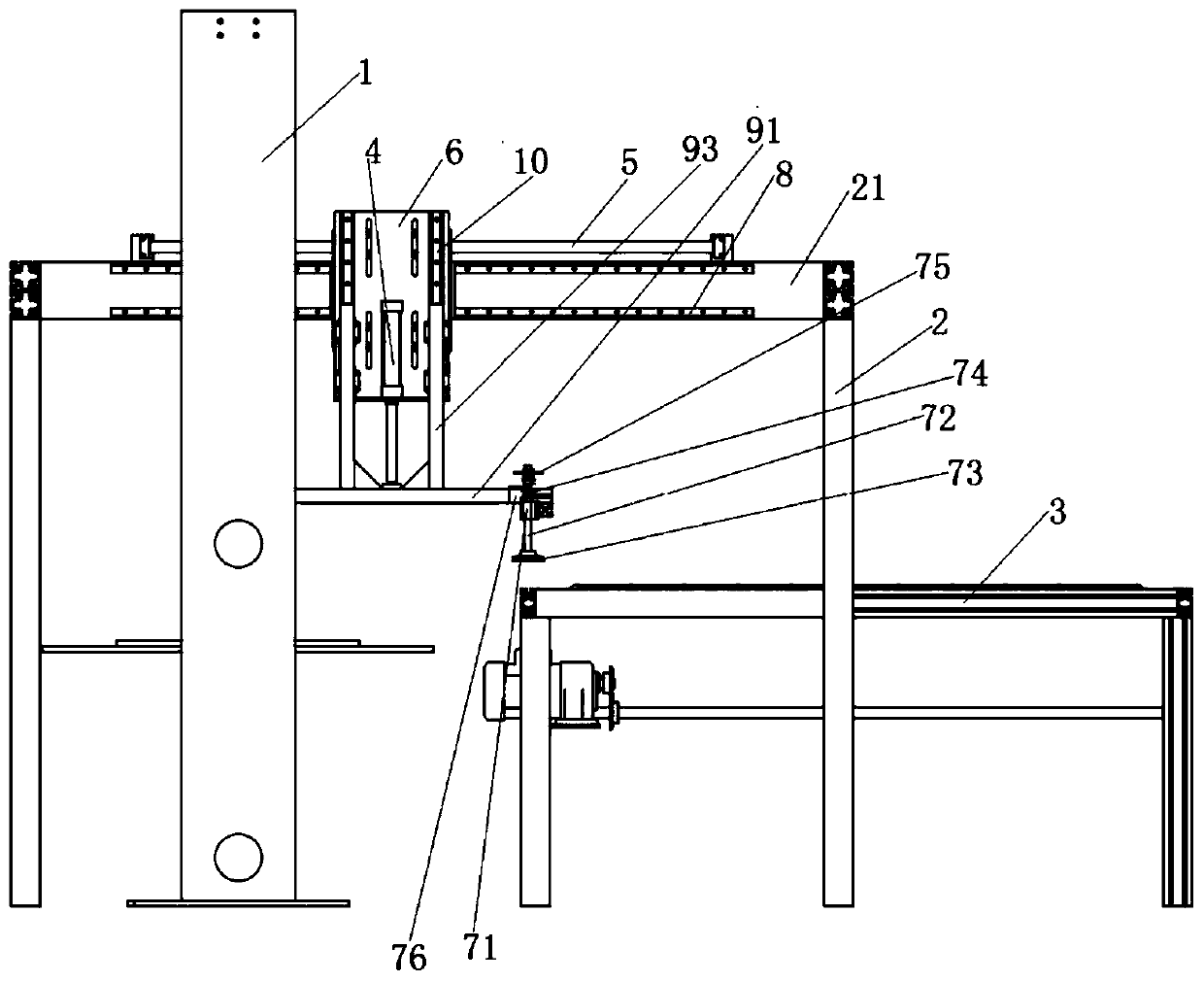

[0023] combine figure 1 and figure 2 , a production line feeding device of this embodiment, including a feeding manipulator and a hydraulic lifting platform 1 that can ensure that the height of the material can be lifted back to the original position after grabbing a piece of raw material, greatly reducing the manipulator's grabbing stroke and reducing the grabbing time , to improve production efficiency; the rear of the hydraulic lifting platform 1 is provided with a stick conveyor 3; the feeding manipulator includes a support frame 2, and the support frame 2 is composed of a beam 21 arranged in the front and rear directions and legs fixed at both ends of the beam 21. One of the legs is located in front of the hydraulic lift 1, and the other leg is located in the middle of the stick conveyor 3; the top surface of the crossbeam 21 is fixedly equipped with a rodless cylinder 5, and the cylinder slider of the rodless cylinder 5 is fixedly installed with a Plate 6, the mounting...

Embodiment 2

[0026] The basic structure of a production line feeding device of this embodiment is the same as that of Embodiment 1, the difference is that: a travel switch 76 is arranged on the position of the longitudinal arm beam 92 facing the pressure plate 75, and the distance between the travel switch 76 and the pressure plate 75 The distance is greater than the drop height of the pressure plate 75 when the vacuum suction cup 73 grabs one piece of raw material, and is smaller than the drop height of the pressure plate 75 when the vacuum suction cup 73 grabs two raw materials, so as to ensure that the manipulator grabs one piece of raw material at a time, and avoids the fact that the manipulator grabs multiple plates at a time. Then affect the normal work of the follow-up process during automatic production.

[0027] After the vacuum suction cup 73 grabs a piece of raw material, the gravity of the raw material drives the optical axis 72 to descend, and at the same time the spring 74 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com