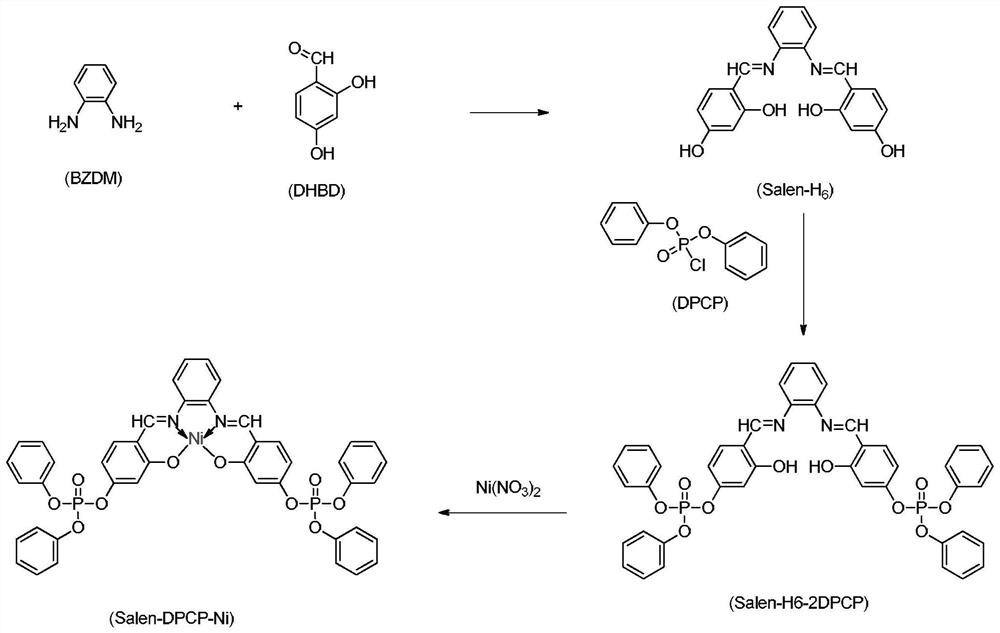

Metal ion flame retardant complex with Schiff base structure and preparation method

A technology of metal ions and Schiff bases, applied in the field of reactive flame retardants, can solve the problems of weakening the combustion of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Metal ion flame retardant complex with Schiff base structure

[0043] The structural formula is as follows

[0044] in,

[0045] Wherein, M is a metal ion, specifically Cu and Fe.

Embodiment 2

[0046] Embodiment 2: Metal ion flame retardant complex with Schiff base structure

[0047] The structural formula is as follows

[0048] in,

[0049] Wherein, M is a metal ion, specifically Ni, Zn.

Embodiment 3

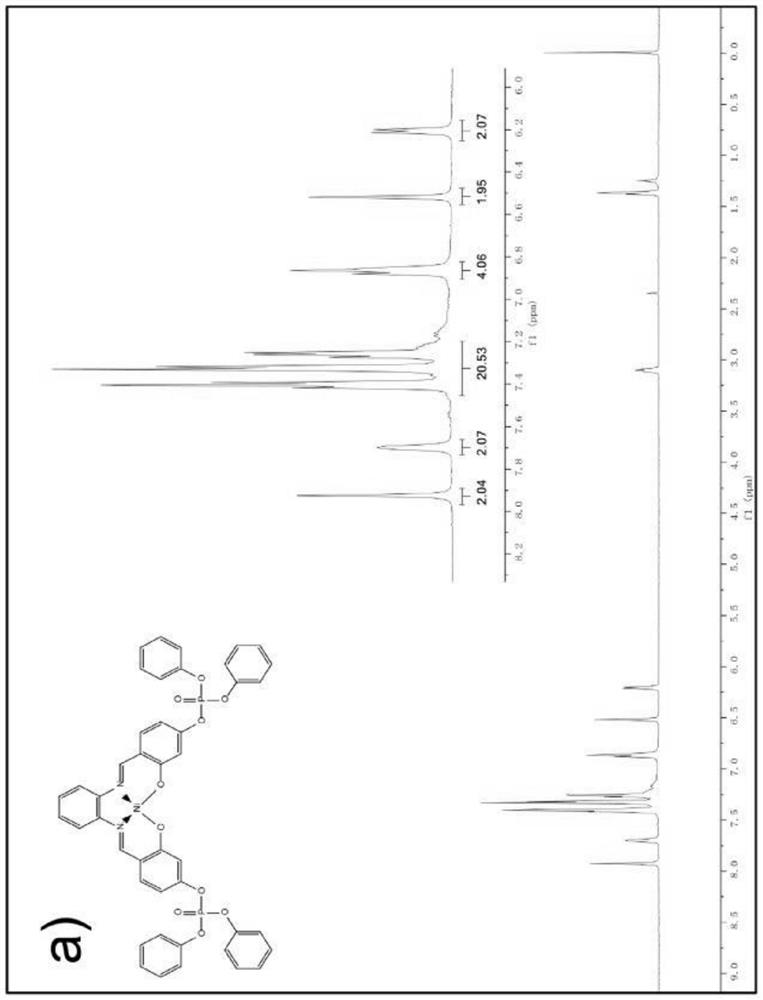

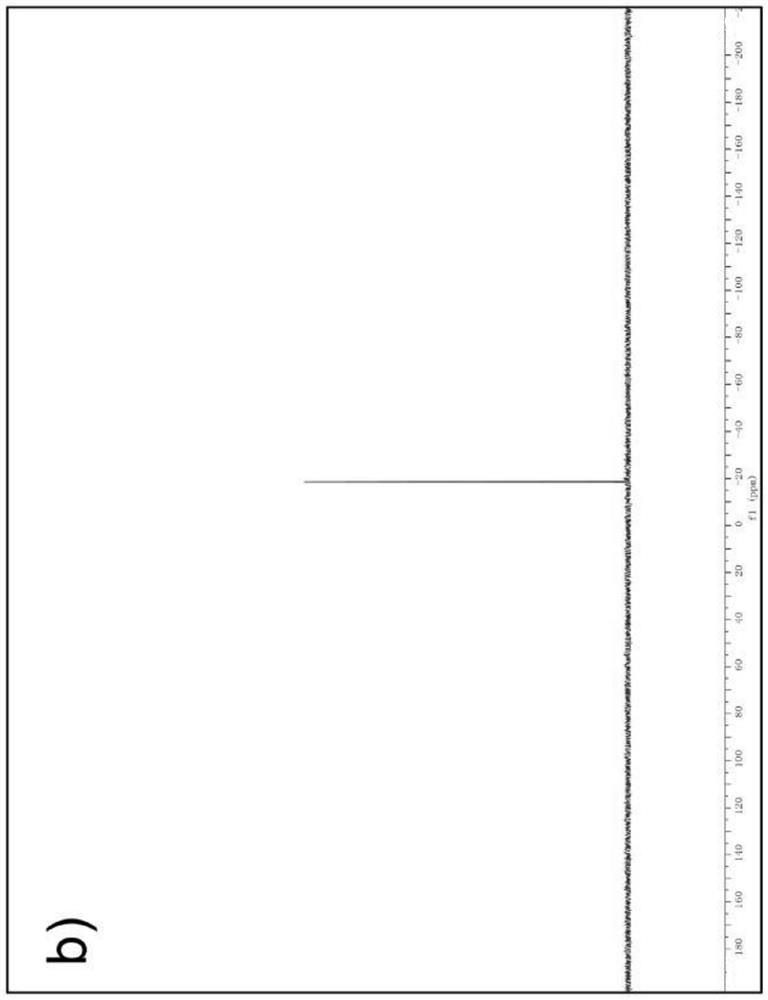

[0051] Add 2.0mol 2,4-dihydroxybenzaldehyde, ethanol, and 1.0mol o-phenylenediamine into a reaction vessel equipped with stirring, heating, and temperature control devices. After the addition is complete, stir and react at 30°C for 12h under nitrogen protection; the yellow The precipitate was filtered under reduced pressure, washed with ethanol, and dried in a vacuum oven to obtain the intermediate product N,N'-bis(2,4-dihydroxyhydrinohydrin)-1,2-phenylenediamine (Salen-H6). Then add 1.0mol Salen-H6, 2.3mol triethylamine and dichloromethane into the reaction vessel equipped with stirring, heating and temperature control devices, and add 2.3mol diphenyl chlorophosphate (DPCP) dropwise at 0°C Into the system, after the addition is complete, stir and react at 30°C for 6h under nitrogen protection; evaporate dichloromethane to dryness under reduced pressure, extract 3 times with dichloromethane, wash the organic phase with deionized water 3 times, and evaporate dichloromethane to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com